100 cfm more with anular and downleg boosters can't beat AFR

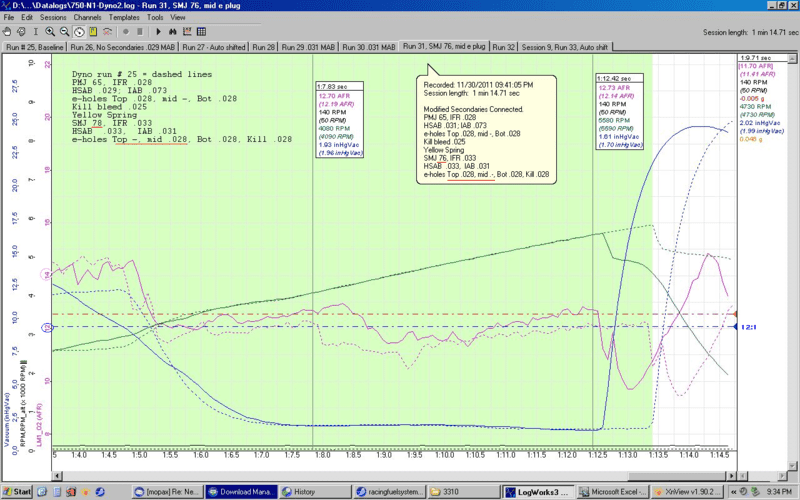

OK. Here's some I've already made screen shots of and marked up.

750 on the chassis dyno.

Solid lines is run #31, which is very similar to the 33 shown in the first post.

Dashed lines are an overlay of an earlier run with larger secondary jets, and a different pair of secondary emulsion holes.

Changes in power are difficult to ascertain as the rpm slope is the only clue.

But it is easier to see the details of the AFR and vacuum.

Those downlegs are going lean, then rich before drifting lean with rpm.

That's why in the photo of the carb you now see wires in the secondary main air bleeds. Would like to get back to the dyno or drag strip with the logger to see how much correction they are doing. I've also moved the secondary IFRs to a low location but that shouldn't anything but the start - if that.

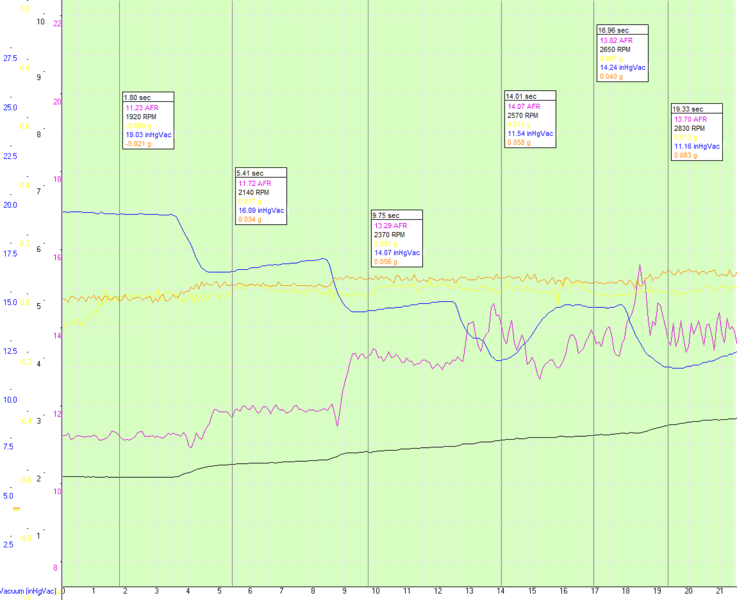

Next is some relatively low speed vacuum crowds. In other words, using the throttle to hold a vacuum reading.

This is the 650 carb and the mallory built MP distributor. With the converter tightened up a little, there were part throttle ping issues and a dead spot that was totally unacceptable for autocrossing.

The vacuum readings seem to be about 1.5"Hg higher than the mechanical gage. May be something to do with my conversion or the MAP sensor.

We can see that increasing throttle brings with it leaner mixture (violet), and more acceleration (orange), until vacuum drops below 12" on the MAP reading. Then AFR gets ragged and there's no corresponding increase in acceleration.

If this was done at higher speed, we'ld know that the power valve needs to open at this point. At these speeds, it was a maybe. Notice it did a little better at 2800 rpm. I think the kill bleed location was causing a delayed reaction on the main circuits. To be continued...

Throttle position would be helpful. It would let us better estimate how much portion is from the transfer slot vs booster, and also see motion related to pump shot.

OK. Here's some I've already made screen shots of and marked up.

750 on the chassis dyno.

Solid lines is run #31, which is very similar to the 33 shown in the first post.

Dashed lines are an overlay of an earlier run with larger secondary jets, and a different pair of secondary emulsion holes.

Changes in power are difficult to ascertain as the rpm slope is the only clue.

But it is easier to see the details of the AFR and vacuum.

Those downlegs are going lean, then rich before drifting lean with rpm.

That's why in the photo of the carb you now see wires in the secondary main air bleeds. Would like to get back to the dyno or drag strip with the logger to see how much correction they are doing. I've also moved the secondary IFRs to a low location but that shouldn't anything but the start - if that.

Next is some relatively low speed vacuum crowds. In other words, using the throttle to hold a vacuum reading.

This is the 650 carb and the mallory built MP distributor. With the converter tightened up a little, there were part throttle ping issues and a dead spot that was totally unacceptable for autocrossing.

The vacuum readings seem to be about 1.5"Hg higher than the mechanical gage. May be something to do with my conversion or the MAP sensor.

We can see that increasing throttle brings with it leaner mixture (violet), and more acceleration (orange), until vacuum drops below 12" on the MAP reading. Then AFR gets ragged and there's no corresponding increase in acceleration.

If this was done at higher speed, we'ld know that the power valve needs to open at this point. At these speeds, it was a maybe. Notice it did a little better at 2800 rpm. I think the kill bleed location was causing a delayed reaction on the main circuits. To be continued...

Throttle position would be helpful. It would let us better estimate how much portion is from the transfer slot vs booster, and also see motion related to pump shot.