Jetting and timing question

Be aware that change in timing can cause an apparent change to AFR because the combustion changed, not because the AFR changed. AFR gage uses a sensor that is effected by leftover O2.

If there is no choke, then they should have nothing to do with starting.

Maybe a few general relationships will be helpful.

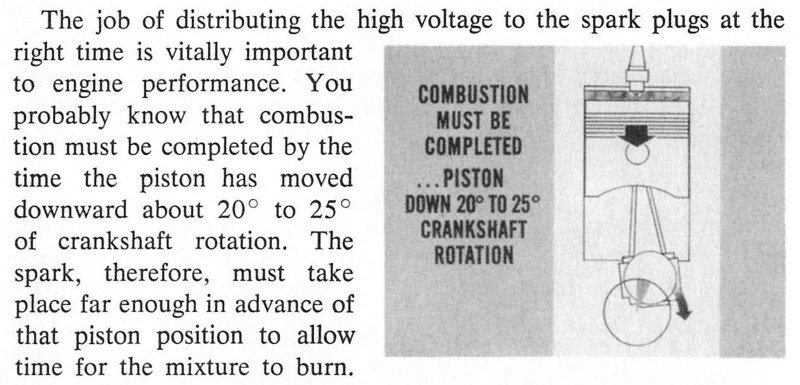

Where the timing ought to be depends most on the compression and engine speed for a given engine and cylinder head.

from: The New Distributor (Session 136), the Master Technician's Service Conference

At starting and idle rpm, there is more time (in fractions of a second) for the combustion to reach maximum just in time to put maximum leverage on the crank.

As rpms increase there is less time for the burn before the piston is past the ideal postion. So the spark is initiated earlier in the crank motion.

However in most engines the burn improves as rpm's increase. That's why the mechanical advance is not always a straight line.

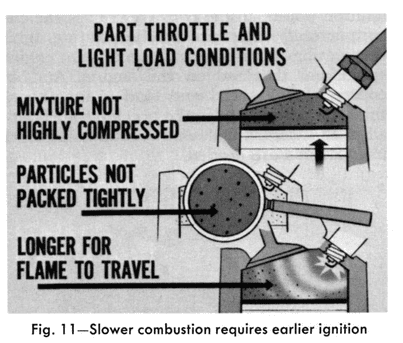

The density of the fuel and air mixture also effects the speed of the burn.

At steady cruising the engine has little load and can run on a leaner mixture.

from: Ignition System Analysis, Master Technician's Service Conference 1969

Adding throttle from stready cruising should lean out the mixture even further, until 1/2 or 3/4 throttle.

All of the lean combustion situations burn slower so need more advance, usually done with vacuum advance.

More than 1/2 or 3/4 throttle requires richer mixtures and vacuum advance (if used) needs to go away.

LOL. I was thinking it might be a 3 circuit 4500. It also could have garbage in the passages. Machining chips.

Should not be related on a 4150 or 4500

the AFR gage will give you some idea of the the effect of any change. That's the main thing to use it for.

Be aware that change in timing can cause an apparent change to AFR because the combustion changed, not because the AFR changed. AFR gage uses a sensor that is effected by leftover O2.

Generally a less dense fuel mixture burns slower and so needs more timing.

The main circuit jetting has little to do with starting conditions for any of the major carburetor types we use.

If there is no choke, then they should have nothing to do with starting.

Maybe a few general relationships will be helpful.

Where the timing ought to be depends most on the compression and engine speed for a given engine and cylinder head.

from: The New Distributor (Session 136), the Master Technician's Service Conference

At starting and idle rpm, there is more time (in fractions of a second) for the combustion to reach maximum just in time to put maximum leverage on the crank.

As rpms increase there is less time for the burn before the piston is past the ideal postion. So the spark is initiated earlier in the crank motion.

However in most engines the burn improves as rpm's increase. That's why the mechanical advance is not always a straight line.

The density of the fuel and air mixture also effects the speed of the burn.

At steady cruising the engine has little load and can run on a leaner mixture.

from: Ignition System Analysis, Master Technician's Service Conference 1969

Adding throttle from stready cruising should lean out the mixture even further, until 1/2 or 3/4 throttle.

All of the lean combustion situations burn slower so need more advance, usually done with vacuum advance.

More than 1/2 or 3/4 throttle requires richer mixtures and vacuum advance (if used) needs to go away.