8.8 swap

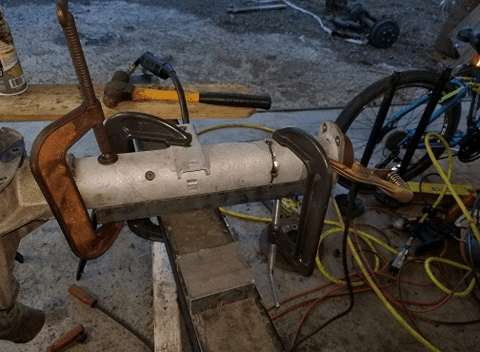

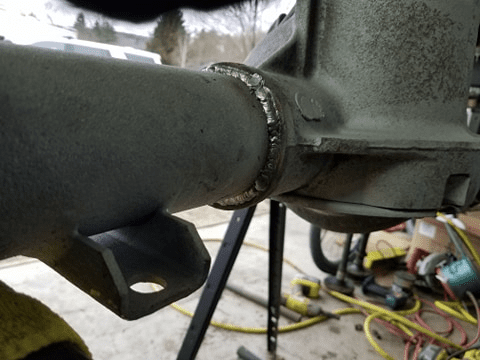

I had today off from work, so I marked out the 8.8, cut it, and welded it up. I tacked it all the way around, remeasuring 4 sides of the tube, after every 8-10 tacks. I then turned the heat up and put a nice thick bead an inch at a time, skipping around, and measuring 4 sides after ever 2-3 welds. It was 17 1/16" from the housing to the inside of the flange at all times. I also welded the center housing to the axle tubes. I am going to grind the weld down with a flap wheel tomorrow, and then fill in if needed:

I had today off from work, so I marked out the 8.8, cut it, and welded it up. I tacked it all the way around, remeasuring 4 sides of the tube, after every 8-10 tacks. I then turned the heat up and put a nice thick bead an inch at a time, skipping around, and measuring 4 sides after ever 2-3 welds. It was 17 1/16" from the housing to the inside of the flange at all times. I also welded the center housing to the axle tubes. I am going to grind the weld down with a flap wheel tomorrow, and then fill in if needed: