Stop in for a cup of coffee

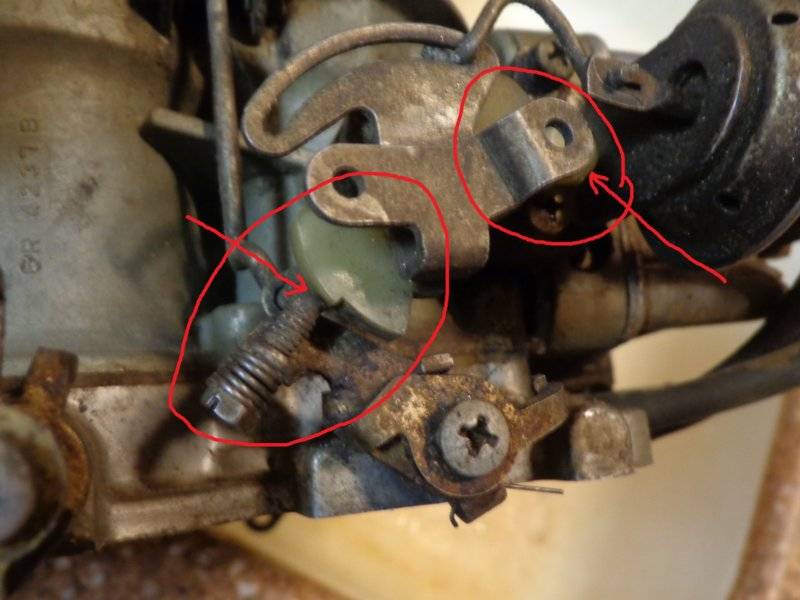

Here's another carb without the electric choke, but you can see the main parts better to see how they work...

This is a shot with the choke in the closed position... You can see on the right side that the choke idle screw is in contact with the highest step on the idle hammer cam... This is not an electric choke carb, so there are only two steps on the cam on the back side of the 'hammer', the electric choke hammer has more steps on the cam... On the left side, you can see that the hammer is in the upward position... On the electric choke the bimetallic spring opens gradually as the engine warms up and causes the hammer to lower gradually as the engine heats up and you give the throttle a quick goose...

Here is a picture of the hammer with the choke in the open position...

Look at the circle on the left side and see the hammer in the down position... Then look at the circles on the right and see that the choke adjustment screw is no longer on any of the ramps for the choke idle cam on the back of the hammer...

You can only adjust the choke idle screws with the carb off the car as there is too much in the way, so you want to study up and know what you need to do to minimize how many times you need to remove the carb and adjust the choke idle screw...

The choke idle will 'override' the warm idle screws on the throttle side when the choke is engaged... Only when the engine is warm and the choke is disengaged will the warm idle screws on the driver's side be in play..

**********************************************************************************************************************************************

BUT BEFORE YOU DO ANY ADJUSTMENTS:

Make sure that you have the choke hooked up to a good 12 volt source... DO NOT HOOK IT UP TO THE COIL + , that will only give 6 volts!!!

I like to hook up the positive 12 volt wire to the input side of the ballast resistor... It's easy to tell, just disconnect both wires from the ballast resistor and put a test light on the negative side of the battery... Then probe each ballast wire connector with the ignition switch in the on position and see which side makes the test light turn on - that is the input side of the ballast resistor... I like to use a flat blade piggyback connector and connect the electric choke positive wire to that one... Then you will have a good 12 volt source when the ignition is in the on position...

************************************************************************************************************************************************

Play with the choke butterfly and the hammer on the choke to get a feel for how it works... You may have to open the throttle plates a little to be able to move the choke and choke hammer...

Here's another carb without the electric choke, but you can see the main parts better to see how they work...

This is a shot with the choke in the closed position... You can see on the right side that the choke idle screw is in contact with the highest step on the idle hammer cam... This is not an electric choke carb, so there are only two steps on the cam on the back side of the 'hammer', the electric choke hammer has more steps on the cam... On the left side, you can see that the hammer is in the upward position... On the electric choke the bimetallic spring opens gradually as the engine warms up and causes the hammer to lower gradually as the engine heats up and you give the throttle a quick goose...

Here is a picture of the hammer with the choke in the open position...

Look at the circle on the left side and see the hammer in the down position... Then look at the circles on the right and see that the choke adjustment screw is no longer on any of the ramps for the choke idle cam on the back of the hammer...

You can only adjust the choke idle screws with the carb off the car as there is too much in the way, so you want to study up and know what you need to do to minimize how many times you need to remove the carb and adjust the choke idle screw...

The choke idle will 'override' the warm idle screws on the throttle side when the choke is engaged... Only when the engine is warm and the choke is disengaged will the warm idle screws on the driver's side be in play..

**********************************************************************************************************************************************

BUT BEFORE YOU DO ANY ADJUSTMENTS:

Make sure that you have the choke hooked up to a good 12 volt source... DO NOT HOOK IT UP TO THE COIL + , that will only give 6 volts!!!

I like to hook up the positive 12 volt wire to the input side of the ballast resistor... It's easy to tell, just disconnect both wires from the ballast resistor and put a test light on the negative side of the battery... Then probe each ballast wire connector with the ignition switch in the on position and see which side makes the test light turn on - that is the input side of the ballast resistor... I like to use a flat blade piggyback connector and connect the electric choke positive wire to that one... Then you will have a good 12 volt source when the ignition is in the on position...

************************************************************************************************************************************************

Play with the choke butterfly and the hammer on the choke to get a feel for how it works... You may have to open the throttle plates a little to be able to move the choke and choke hammer...