I went with the cope racing bolt in, I think it’s about 100 bucks for the stock modified four bolt. There’s better sprags out there for more money. But a stocker should be fine if you’re on a budget.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time for 727 rebuild.

- Thread starter swifty

- Start date

-

scott657

Well-Known Member

Ill be doing one soon. 1 thing I haven't seen is a tutorial on is removing and replacing the bushings. Any insight on that would be great.

Funny you’re title is almost the same as mine.

727 Time to rebuild

727 Time to rebuild

CudaFactHackJob

Well-Known Member

Bushings? Use a big flat plate to get them started if there's room. Tap, tap, tap; a little bit at a time.

swifty

Well-Known Member

Question on torque converter. I am sending emails to different companies. Which Dynamic is the one everyone recommends? If you google dynamic torque converter you get 3 different companies. Where are they located?

swifty

Well-Known Member

Ill be doing one soon. 1 thing I haven't seen is a tutorial on is removing and replacing the bushings. Any insight on that would be great.

I am dropping mine off at a local shop. He is not busy and could use the business. He has always been fair with me in the past.

The tailshaft I just cut a groove in with hack saw blade. Then push in on itself. It will split then pull it out. I use on old valve from a Chevy to drive it in.

I cleaned it up with emory cloth and sanded down the support with some 180 grit. Was able to get it in with a block of wood and some tapping. Real tight. I think I will take a little more off and put it in the freezer.

Next question, my sprag was a little loose and some of the spring tabs were bent. I took it out and it has quite a bit of wear. So I plan on replacing it. Should I look at a bolt in or is a regular one good enough for my application?

I would definitely replace it...bolt in if you have the coin...

Jeff

swifty

Well-Known Member

I would definitely replace it...bolt in if you have the coin...

Jeff

I ordered the Cope bolt in about $100.

swifty

Well-Known Member

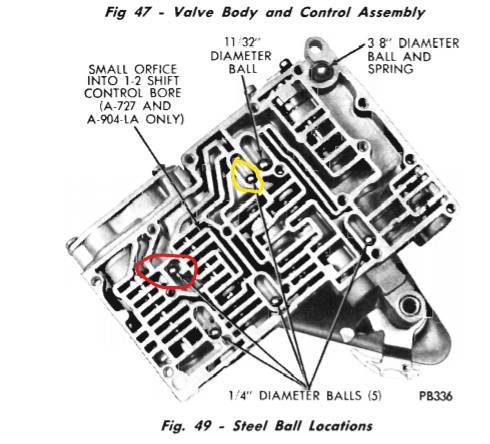

I disassembled valve body and cleaned up. One thing I found was I only have 6 check balls. Unfortunately one of the six fell out during disassembly so I am not sure were it goes. The pockets I circled did not have check balls.

I found on some shift kits the red marked ball is sometimes removed. Is this right or should I get another steel ball?

I found on some shift kits the red marked ball is sometimes removed. Is this right or should I get another steel ball?

CudaFactHackJob

Well-Known Member

Just follow the shift kit instructions. There are several different variations on check balls. But you should post a pic of YOUR valve body because there are sometimes subtle differences.

swifty

Well-Known Member

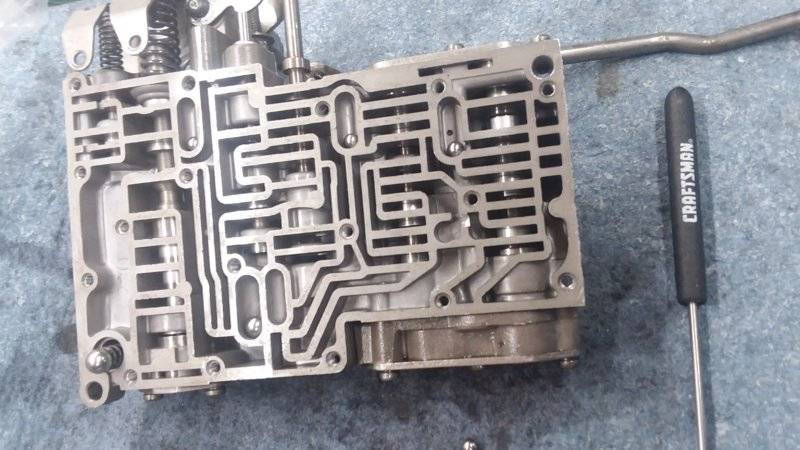

Here is what I found when I took apart.

swifty

Well-Known Member

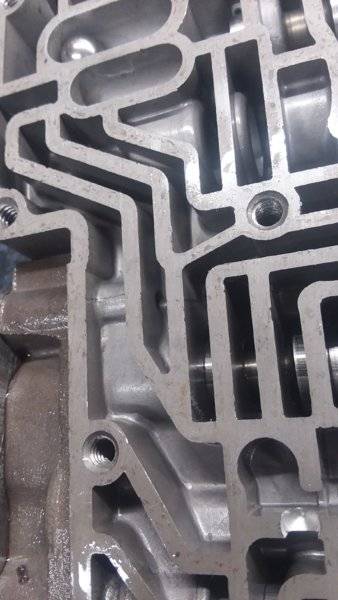

I do not know what kind of shift kit it has. There is no spring under accumulator or rod. A cup with hole in this passage.

This passage could be drilled out.

Anything else to look for to help identify?

This passage could be drilled out.

Anything else to look for to help identify?

CudaFactHackJob

Well-Known Member

TF-2. No ball goes in the hole where the wall is cut out.

swifty

Well-Known Member

What about the accumulator? Spring, no spring or rod?

swifty

Well-Known Member

I have trans together to check clearances.

The gear train endplay was .018.

Input shaft .077

Front clutch with a flat snap ring .074

Rear clutch .032.

Input shaft is within tolerance but barely. Look at tightening up?

Front clutch is 4 disc Red Eagles. Should I have more clearance. Should I also have a wavy snap ring?

One other thing I found odd was the front clutch only had 8 springs. I found from from Tom Hand book it should have 9. This is a 72 360 trans. Any thoughts?

The gear train endplay was .018.

Input shaft .077

Front clutch with a flat snap ring .074

Rear clutch .032.

Input shaft is within tolerance but barely. Look at tightening up?

Front clutch is 4 disc Red Eagles. Should I have more clearance. Should I also have a wavy snap ring?

One other thing I found odd was the front clutch only had 8 springs. I found from from Tom Hand book it should have 9. This is a 72 360 trans. Any thoughts?

CudaFactHackJob

Well-Known Member

I like a wavy snap ring in the front drum to make the reverse engagement softer; unless you have a stall converter. Those come with usually a thick washer and a thin washer between the drums and at the pump; so I usually run two thins at the pump an a thick between the drums, or you could get a thicker button for the front of the output shaft. Maybe run three thins altogether with no thick; might get you down to .040 end play. But only put one thrust between the drums. I like a little more clearance than .032 in the forward clutch; like .050

swifty

Well-Known Member

Let me start over for endplay. I did not have tail shaft on when I checked because I was waiting for bushing driver. Now is .058. Is that still too loose?

If I switch around snap rings I could get .046 on rear clutch. But then I would need a thin snap ring for front. With a flat snap ring on front and 4 discs what should the front clearance be?

If I switch around snap rings I could get .046 on rear clutch. But then I would need a thin snap ring for front. With a flat snap ring on front and 4 discs what should the front clearance be?

scott657

Well-Known Member

Following intently

swifty

Well-Known Member

Does any one have TF-2 instructions link or copy they can email? I can't seem to fine one.

CudaFactHackJob

Well-Known Member

I like endplay about .020. Put the pump in a vise and air apply the clutch packs; the clearance will open up when the extra fluid is squished out.

scott657

Well-Known Member

send me your emailDoes any one have TF-2 instructions link or copy they can email? I can't seem to fine one.

scott657

Well-Known Member

scanned and ready to deliver

swifty

Well-Known Member

Just want to verify something when it comes to input shaft endplay. I just pushed in and then measured pulling out about .060. I see some people stand it on output shaft. If i push the input shaft in. then push in the output shaft to take out bearing play, then measure, I get .040. Is that good? What is the proper procedure?

CudaFactHackJob

Well-Known Member

The way you got .060. .040 is max factory, I like .020 to help that direct drum from wobbling too much.

scott657

Well-Known Member

so will that require a thicker washer between input and output shafts

-