Ring Gap?

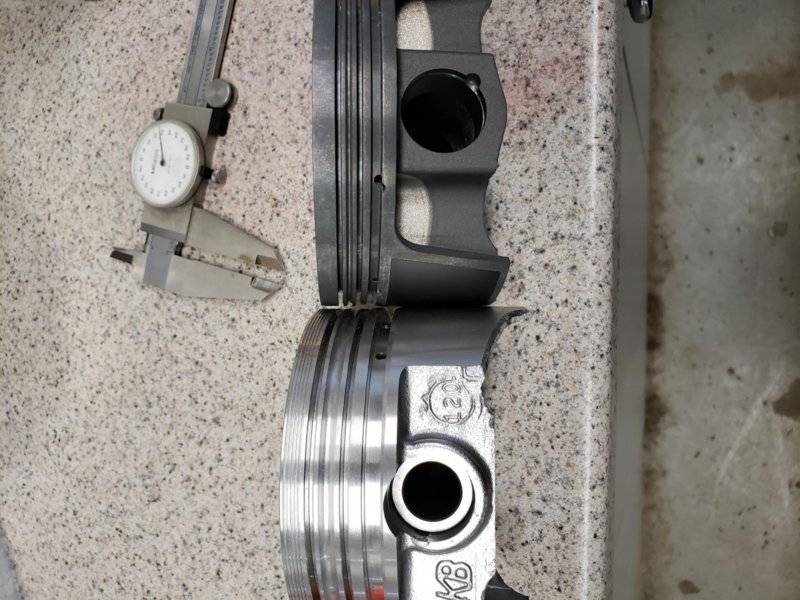

I guess he doesn't really understand his product totally. I have provided a photo of a KB on the left and a Mahle forging on the right. The KB has a top ring land of .280" and the Mahle .240". The Mahle does not require any additional top ring gap unlike the KB. If its placement and not alloy type as you and KB suggest then please explain. I'm curious now. J.Rob

I guess he doesn't really understand his product totally. I have provided a photo of a KB on the left and a Mahle forging on the right. The KB has a top ring land of .280" and the Mahle .240". The Mahle does not require any additional top ring gap unlike the KB. If its placement and not alloy type as you and KB suggest then please explain. I'm curious now. J.Rob