Project “Ghost Duster”, 1970 Duster Corner Carver

The rear cross member was composed of three welded pieces. The outer ones spanned the width of the trunk drop downs and were previously patched....terribly.

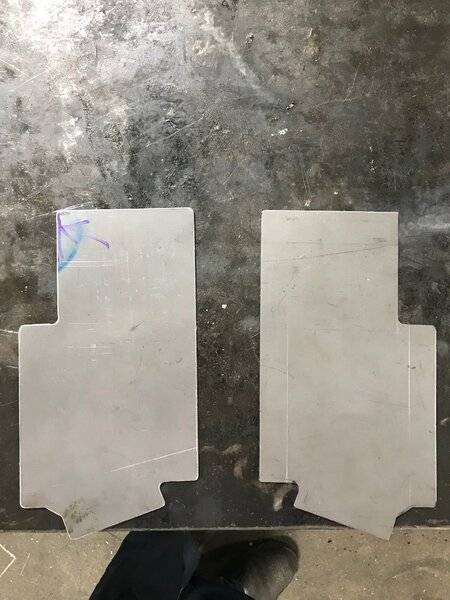

Since I had to cut them back to install the trunk drop downs, I cut the patch out plus a bit more until I hit solid steel. Then I laid out new crossmember ends on sheet metal and made them long enough to fill in for the extra rust that was removed. Then cut them out on a shear and bandsaw.

Since I had to cut them back to install the trunk drop downs, I cut the patch out plus a bit more until I hit solid steel. Then I laid out new crossmember ends on sheet metal and made them long enough to fill in for the extra rust that was removed. Then cut them out on a shear and bandsaw. I bent the flanges, as the original piece, on the brake. Here is an OEM beside the new and improved version.

I bent the flanges, as the original piece, on the brake. Here is an OEM beside the new and improved version. I slit the overlapping 5/8” on the radius of the top flange to make sure the lower flanges sat flush on the drop down. Then I drilled holes for plug welding and burned her home.

I slit the overlapping 5/8” on the radius of the top flange to make sure the lower flanges sat flush on the drop down. Then I drilled holes for plug welding and burned her home.

Dressed the welds and coated with POR15.

Dressed the welds and coated with POR15.

Both sides needed the same treatment, looks great now and is super solid.

View attachment 1715535894

The rear cross member was composed of three welded pieces. The outer ones spanned the width of the trunk drop downs and were previously patched....terribly.

Both sides needed the same treatment, looks great now and is super solid.

View attachment 1715535894