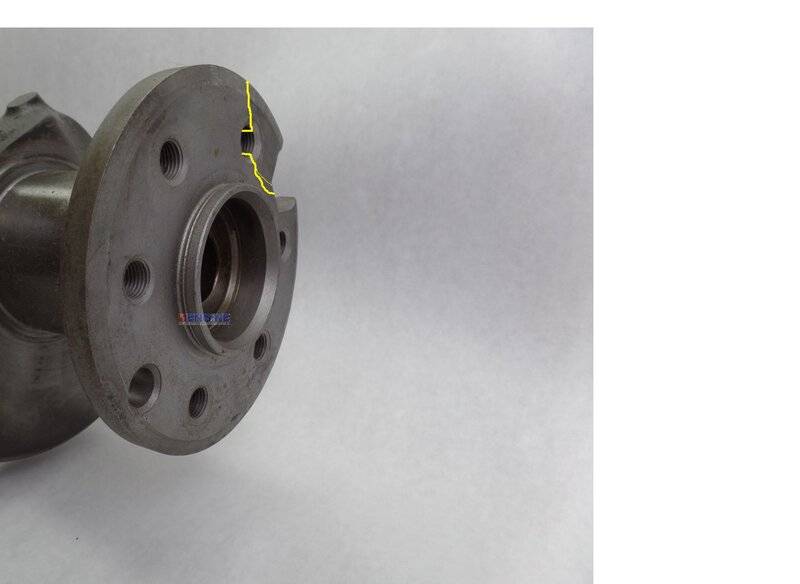

Damaged crank flange

Had this 340 turned mains 360 crank forever after Fedex damaged it in shipping. Didnt want to toss it so Im doing a derust session on it. I realized the chip in the flange is not as bad as I remembered it being, its just a corner chip between a bolt hole and the void. If I were to actually put a bolt in whats left of that hole (not even sure it would hold one) and then run a flexplate, do you think the strength would be all that reduced? It would be a hack 318 stroker build (cleaner than UTG/Nicks motor at least!) using low compression cast truck pistons and open 360 heads and the thickest pair of head gasket I can mic out of the 13 I have collected at various swap meets. The chip and the location:

Figured I could at least epoxy it and put a bolt in it with locktite red 271 just for the balance of it if it would matter being so close to the axis? Looks like crack is not on thrust side of flange it that existed.

Had this 340 turned mains 360 crank forever after Fedex damaged it in shipping. Didnt want to toss it so Im doing a derust session on it. I realized the chip in the flange is not as bad as I remembered it being, its just a corner chip between a bolt hole and the void. If I were to actually put a bolt in whats left of that hole (not even sure it would hold one) and then run a flexplate, do you think the strength would be all that reduced? It would be a hack 318 stroker build (cleaner than UTG/Nicks motor at least!) using low compression cast truck pistons and open 360 heads and the thickest pair of head gasket I can mic out of the 13 I have collected at various swap meets. The chip and the location:

Figured I could at least epoxy it and put a bolt in it with locktite red 271 just for the balance of it if it would matter being so close to the axis? Looks like crack is not on thrust side of flange it that existed.