New 408 build finally started

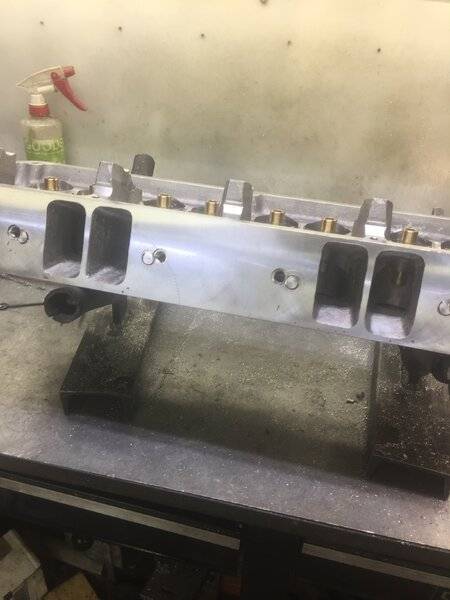

So for 4.5 hours Friday night and 5 hours Saturday night my buddy and I knocked the heads of the aluminum bolts and faced them, laid out the new Indy intake pattern, drilled then, I hand tapped them, then we set up one head to relocate the new pushrod holes. Each head needed reset twice for the four holes on each head. We milled a 5/8 hole so now I will debuted everything by hand and test fit each and every (8) hole with rockers, test springs, and pushrods. Would I recommend doing this. Aaaaaa NO. Will I do it again? Probably because I have the other set of .350 rockers. I would probably open the port to a max of 1.150 and knowing the 5 degree pushrod angle could probably do it on my drill press. And shirt between the port and stock Edelbrock intake pattern but I would do some port measurements on my Super Victor intake.

So for 4.5 hours Friday night and 5 hours Saturday night my buddy and I knocked the heads of the aluminum bolts and faced them, laid out the new Indy intake pattern, drilled then, I hand tapped them, then we set up one head to relocate the new pushrod holes. Each head needed reset twice for the four holes on each head. We milled a 5/8 hole so now I will debuted everything by hand and test fit each and every (8) hole with rockers, test springs, and pushrods. Would I recommend doing this. Aaaaaa NO. Will I do it again? Probably because I have the other set of .350 rockers. I would probably open the port to a max of 1.150 and knowing the 5 degree pushrod angle could probably do it on my drill press. And shirt between the port and stock Edelbrock intake pattern but I would do some port measurements on my Super Victor intake.