checking gauge function

Do a search, I'm not trynna be mean. There are hundreds of posts on this, ................

You need to rig some test resistors, or use a gas tank sender which you can move and set to a resistance with your meter

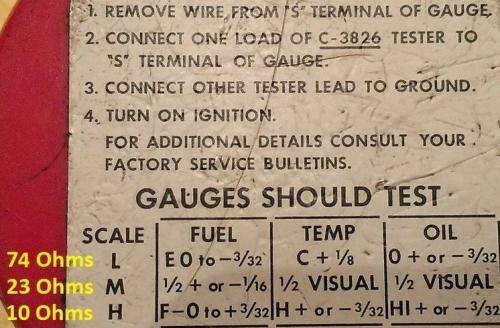

This is a photo of an aftermarket gauge tester......just like the one in the service manuals.........and they photoshopped the resistances in yellow

What you need and need to do..........Some of this may be different, it has been 40 years since I've screwd with a B Ralley dash cluster, I'm speaking of A bodies, appy if you will

1....Make certain the pc board harness connector pins are tight and undamaged. They are swedged/ riveted, so clean and solder them.

2....Get a solid state IVR and if it plugs into the cluster make certain the connector contacts are clean and continuous. On A bodies, they need to be soldered jumpers to connect to the PC board traces

3....Loosen/ tighten the gauge studs several times to be sure the gauges are making contact.

4....Clusters are poorly grounded by the mounting screws. Find a ground point and solder/ connect a grounding pigtail which you can bolt to the column suppor/ dash frame

5...."Rig" the cluster to a battery, make sure you ground the appropriate point on the cluster. . Apply the appropriate test resistor to ground at the gauge sender terminal, and wait a few seconds for the guage to stabilize. And see if it reads what it should

6....If you have a variable power supply it would be wise to check the gauges at 14V which is what the system "runs" at. If you don't have that, just nose a running vehicle into the garage and use jumper wires to power the cluster off the running vehicle. This will give you the desired 14V

NOTice in the destructions for the tester, that all 2 or 3 gauges read the same with the same resistor at each one. This will give you a "double check" because, say, if the fuel gauge works and the temp is different with same test resistance, you have a problem

Do a search, I'm not trynna be mean. There are hundreds of posts on this, ................

You need to rig some test resistors, or use a gas tank sender which you can move and set to a resistance with your meter

This is a photo of an aftermarket gauge tester......just like the one in the service manuals.........and they photoshopped the resistances in yellow

What you need and need to do..........Some of this may be different, it has been 40 years since I've screwd with a B Ralley dash cluster, I'm speaking of A bodies, appy if you will

1....Make certain the pc board harness connector pins are tight and undamaged. They are swedged/ riveted, so clean and solder them.

2....Get a solid state IVR and if it plugs into the cluster make certain the connector contacts are clean and continuous. On A bodies, they need to be soldered jumpers to connect to the PC board traces

3....Loosen/ tighten the gauge studs several times to be sure the gauges are making contact.

4....Clusters are poorly grounded by the mounting screws. Find a ground point and solder/ connect a grounding pigtail which you can bolt to the column suppor/ dash frame

5...."Rig" the cluster to a battery, make sure you ground the appropriate point on the cluster. . Apply the appropriate test resistor to ground at the gauge sender terminal, and wait a few seconds for the guage to stabilize. And see if it reads what it should

6....If you have a variable power supply it would be wise to check the gauges at 14V which is what the system "runs" at. If you don't have that, just nose a running vehicle into the garage and use jumper wires to power the cluster off the running vehicle. This will give you the desired 14V

NOTice in the destructions for the tester, that all 2 or 3 gauges read the same with the same resistor at each one. This will give you a "double check" because, say, if the fuel gauge works and the temp is different with same test resistance, you have a problem