Magnum Head porting for the beginner, Pt II Exh

We ended the first installment finding the Int port hitting 257 cfm.

Not bad for a port just about anyone could duplicate in their garage.

Although I was happy to hit this mark, without anything elaborate, it also meant the Exhaust side had it's work cut out for it.

A lifetime ago, it was thought exhaust port flow percentage of 70% was all one would needed.

As conventional wisdom prevailed, this percentage jumped in 5% increments over the years, to the point of 80% in many circles. At least in the magazines.

Reher & Morrison, as well as many others still contend 60% is enough.

I'm sure there are some on this forum who may have differing opinions on this as well.

And that's ok ! I want to hear their opinions too !

I think the key thing here is keeping the apples away from the oranges.. A race only application may be ok with, say 70%, but one who is running a street deal with closed exhaust may get a bump from a higher percentage.

How does the Magnum Exh port faire? Well, in OEM form, about 73%. Wow, that's cool. This could be why so many are getting good to great results with CAT backs and such on their Mag power trucks.

I used to own a beautiful 2001 Dakota RT that responded very well from a well crafted DIY Y-pipe.

Ok enough of that !

As in the Int test, I freshened up the Valve Job first.

This is what I ended up with.. pass-able.

Mag Exh baseline OE port./ 35°back cut .125 wide .090 seat

.050 31.2 /27.0

.100 55.8 /59.9

.150 80.7 /84.3

.200 104.9 /108.4

.250 124.9 /126.2

.300 138.8 /138.0

.350 146.6 /148.3

.400 151.3 /152.3

.450 154.0 /154.5

.500 155.8 /157.2

.550 156.9 /156.5

.600 157.4 /157.3

As you can see in the Baseline Test, this port is starting to flatten out even at .350 lift, and almost completely by .450. It really could be better, but at 73%, it gets by.

But, we're at 257 cfm @.500 on the Int. We NEED more, even just to hit 70% of that! which is 180 cfm. Preferably at .500 lift.

The BC valve helped in the lower lifts to about .300. The .050 lift point was really noisy. probably due to the ledges in the chamber. We'll fix that later.

Before we get to step 2, I'd like to point out a few things..

The NET valve area is 1.984 sq in (valve area - stem area =1.984)

The Bowl area (OE) is 1.430

A rough approximation of area between the SSR and guide is less than 1.25 (yes 1.25)

Port area at the gasket (end port 1,7, 2,8) is 1.640 (the middle ports are smaller due to the angle on the ports lower half and flows about 5 cfm less )

Obviously, there's a major disparity in CSA in a span of merely 2.3" of port length.

The only saving grace in this port (in my view) is the generous SSR. Even though the majority of port flow is upon the roof.

Seems dismal, doesn't it ? Let's press on.

Let's open the bowl up. There's a factory counter bore below the VJ, but only visible 2/3 the way around. Do the best you can to follow this the whole way around. take it all the way down to the guide. I used a 1/2" Oval burr here.

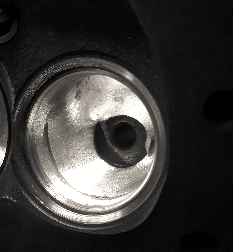

Something like this:

You can see a partial shadow of this counter bore.

Test 2 opened bowl.

.050 28.0

.100 64.3

.150 88.5

.200 110.1

.250 127.8

.300 143.7

.350 155.5

.400 161.6

.450 164.6

.500 166.9

.550 168.9

.600 170.1

Well, that was a pretty handsome gain, given the major pinch in the SSR/Guide area !!

I'm encouraged ! 13 more cfm, and we'll have hit our target of 180.

Now let's thin the guide some. About like this (sorry, it's a bit dark):

.050 28.6

.100 65.4

.150 91.4

.200 112.1

.250 130.5

.300 147.5

.350 160.7

.400 167.5

.450 170.2

.500 172.1

.550 173.9

.600 175.2

Ok, this is getting fun now !

Like most Exh ports, the roof has a problem. A hump, like you see here:

I scratched out a parameter here with a layout pencil.

I scratched out a parameter here with a layout pencil.

This hump (sorry hard to see) needs to be gone.

Problem is, we don't know how thick it is here. So, in another port I previously ported, I found out. See below:

That's correct, I drilled a hole. My apologies again, its hard to make out but, that hole is approximately .125 (1/8") deep/thick. (I'll tap it 1/4-20 and put a set screw in it for future testing)

That's correct, I drilled a hole. My apologies again, its hard to make out but, that hole is approximately .125 (1/8") deep/thick. (I'll tap it 1/4-20 and put a set screw in it for future testing)

With that, grind away! just make it flat. Remove about .080" at the apex.

Roof made flat test:

.050 28.4

.100 64.8

.150 90.5

.200 112.1

.250 131.2

.300 149.2

.350 162.7

.400 170.1

.450 173.6

.500 176.0

.550 177.9

.600 179.9

A gain, but smaller than the last test. Our restriction is in another area.

My guess it's in the factory type Valve Job. Like with the Int, I'm going to use a much larger stone to clean up some of the ledges above the factory top cut.

I will also move the seat out to a diameter of 1.590. .030 smaller than the valve. Then a 60° bottom hopefully .080 wide and finish cut of 70°

Sorry, got all excited and forgot to take a pic. (I know, I"m fired)

.050 28.0

.100 57.0

.150 92.9

.200 116.0

.250 135.8

.300 153.0

.350 165.6

.400 171.3

.450 173.8

.500 176.4

.550 178.8

.600 180.2

The gains are slowing down... still a problem elsewhere.

The noise in the low lift came back.. Let's debur it.

That's better!

Debur test:

.050 28.7

.100 56.0 (humm)

.150 93.3

.200 117.1

.250 141.0

.300 158.2

.350 168.6

.400 172.9

.450 175.4

.500 177.7

.550 179.5

.600 180.5

Some nice gains in the mid lifts.. But still not responding like we need it to. We're sooo close.

We haven't touched that SSR. It's pucker time. I'm not ready to punt, yet..

This is what I did:

The light green is where I started to grind, the darker green is where I removed about .035" worth of SSR, and the longer green is showing the boundary line I ground to while I also widened the port some.

The Hail Mary to 180 cfm test:

.050 29.0 (?!)

.100 57.8

.150 94.5

.200 118.6

.250 141.2

.300 158.2

.350 168.7

.400 173.7

.450 176.6 (feeling better..)

.500 179.1

.550 181.1

.600 182.2

Just in the nick of time! are you feeling the love right now?!

In the back of my mind, Maxwell Smart is saying, '..missed it by THAT much!'

More flow probably could be had by getting after that roof some more, Definitely the pinch between the SSR/guide area.

Taking a break for now. Let me know what you think.

I"m just glad we met the goal.

We ended the first installment finding the Int port hitting 257 cfm.

Not bad for a port just about anyone could duplicate in their garage.

Although I was happy to hit this mark, without anything elaborate, it also meant the Exhaust side had it's work cut out for it.

A lifetime ago, it was thought exhaust port flow percentage of 70% was all one would needed.

As conventional wisdom prevailed, this percentage jumped in 5% increments over the years, to the point of 80% in many circles. At least in the magazines.

Reher & Morrison, as well as many others still contend 60% is enough.

I'm sure there are some on this forum who may have differing opinions on this as well.

And that's ok ! I want to hear their opinions too !

I think the key thing here is keeping the apples away from the oranges.. A race only application may be ok with, say 70%, but one who is running a street deal with closed exhaust may get a bump from a higher percentage.

How does the Magnum Exh port faire? Well, in OEM form, about 73%. Wow, that's cool. This could be why so many are getting good to great results with CAT backs and such on their Mag power trucks.

I used to own a beautiful 2001 Dakota RT that responded very well from a well crafted DIY Y-pipe.

Ok enough of that !

As in the Int test, I freshened up the Valve Job first.

This is what I ended up with.. pass-able.

Mag Exh baseline OE port./ 35°back cut .125 wide .090 seat

.050 31.2 /27.0

.100 55.8 /59.9

.150 80.7 /84.3

.200 104.9 /108.4

.250 124.9 /126.2

.300 138.8 /138.0

.350 146.6 /148.3

.400 151.3 /152.3

.450 154.0 /154.5

.500 155.8 /157.2

.550 156.9 /156.5

.600 157.4 /157.3

As you can see in the Baseline Test, this port is starting to flatten out even at .350 lift, and almost completely by .450. It really could be better, but at 73%, it gets by.

But, we're at 257 cfm @.500 on the Int. We NEED more, even just to hit 70% of that! which is 180 cfm. Preferably at .500 lift.

The BC valve helped in the lower lifts to about .300. The .050 lift point was really noisy. probably due to the ledges in the chamber. We'll fix that later.

Before we get to step 2, I'd like to point out a few things..

The NET valve area is 1.984 sq in (valve area - stem area =1.984)

The Bowl area (OE) is 1.430

A rough approximation of area between the SSR and guide is less than 1.25 (yes 1.25)

Port area at the gasket (end port 1,7, 2,8) is 1.640 (the middle ports are smaller due to the angle on the ports lower half and flows about 5 cfm less )

Obviously, there's a major disparity in CSA in a span of merely 2.3" of port length.

The only saving grace in this port (in my view) is the generous SSR. Even though the majority of port flow is upon the roof.

Seems dismal, doesn't it ? Let's press on.

Let's open the bowl up. There's a factory counter bore below the VJ, but only visible 2/3 the way around. Do the best you can to follow this the whole way around. take it all the way down to the guide. I used a 1/2" Oval burr here.

Something like this:

You can see a partial shadow of this counter bore.

Test 2 opened bowl.

.050 28.0

.100 64.3

.150 88.5

.200 110.1

.250 127.8

.300 143.7

.350 155.5

.400 161.6

.450 164.6

.500 166.9

.550 168.9

.600 170.1

Well, that was a pretty handsome gain, given the major pinch in the SSR/Guide area !!

I'm encouraged ! 13 more cfm, and we'll have hit our target of 180.

Now let's thin the guide some. About like this (sorry, it's a bit dark):

.050 28.6

.100 65.4

.150 91.4

.200 112.1

.250 130.5

.300 147.5

.350 160.7

.400 167.5

.450 170.2

.500 172.1

.550 173.9

.600 175.2

Ok, this is getting fun now !

Like most Exh ports, the roof has a problem. A hump, like you see here:

This hump (sorry hard to see) needs to be gone.

Problem is, we don't know how thick it is here. So, in another port I previously ported, I found out. See below:

With that, grind away! just make it flat. Remove about .080" at the apex.

Roof made flat test:

.050 28.4

.100 64.8

.150 90.5

.200 112.1

.250 131.2

.300 149.2

.350 162.7

.400 170.1

.450 173.6

.500 176.0

.550 177.9

.600 179.9

A gain, but smaller than the last test. Our restriction is in another area.

My guess it's in the factory type Valve Job. Like with the Int, I'm going to use a much larger stone to clean up some of the ledges above the factory top cut.

I will also move the seat out to a diameter of 1.590. .030 smaller than the valve. Then a 60° bottom hopefully .080 wide and finish cut of 70°

Sorry, got all excited and forgot to take a pic. (I know, I"m fired)

.050 28.0

.100 57.0

.150 92.9

.200 116.0

.250 135.8

.300 153.0

.350 165.6

.400 171.3

.450 173.8

.500 176.4

.550 178.8

.600 180.2

The gains are slowing down... still a problem elsewhere.

The noise in the low lift came back.. Let's debur it.

That's better!

Debur test:

.050 28.7

.100 56.0 (humm)

.150 93.3

.200 117.1

.250 141.0

.300 158.2

.350 168.6

.400 172.9

.450 175.4

.500 177.7

.550 179.5

.600 180.5

Some nice gains in the mid lifts.. But still not responding like we need it to. We're sooo close.

We haven't touched that SSR. It's pucker time. I'm not ready to punt, yet..

This is what I did:

The light green is where I started to grind, the darker green is where I removed about .035" worth of SSR, and the longer green is showing the boundary line I ground to while I also widened the port some.

The Hail Mary to 180 cfm test:

.050 29.0 (?!)

.100 57.8

.150 94.5

.200 118.6

.250 141.2

.300 158.2

.350 168.7

.400 173.7

.450 176.6 (feeling better..)

.500 179.1

.550 181.1

.600 182.2

Just in the nick of time! are you feeling the love right now?!

In the back of my mind, Maxwell Smart is saying, '..missed it by THAT much!'

More flow probably could be had by getting after that roof some more, Definitely the pinch between the SSR/guide area.

Taking a break for now. Let me know what you think.

I"m just glad we met the goal.