Is the kickdown linkage set up right?

What you see in posts 8 & 10 is correct.

The Chrysler video shows the correct method of adjustment. You can read and see the details by going to the booklet here,

Master Technician Service Conference - Chrysler's Training for Mechanics , under 1971.

Some of what pearljam posted is incorrect. Yes passing gear is simply the downshift. However it can be 2nd to 1st, 3rd to 2nd etc.

Later torqueflites were designed for 'part throttle' downshift.

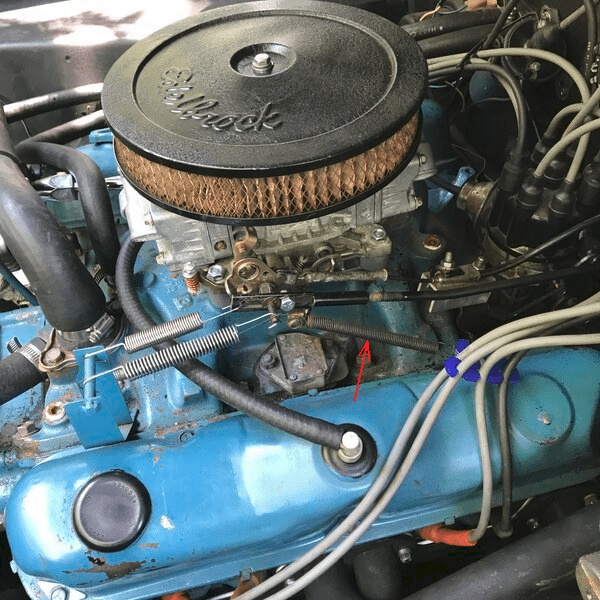

Some clever bracketing you've done.

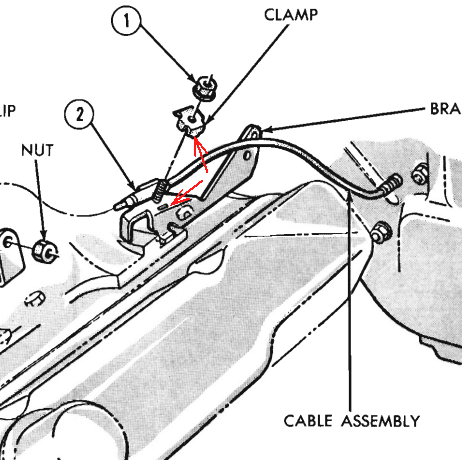

Throttle. My suggestion is to reorient the hold down clamp so it looks like the show manual shows. This provides more leverage so will hold the cable housing more securely.

Tip. Have a friend help to ensure the throttle is actual completely open when the pedal is floored. No more, no less.

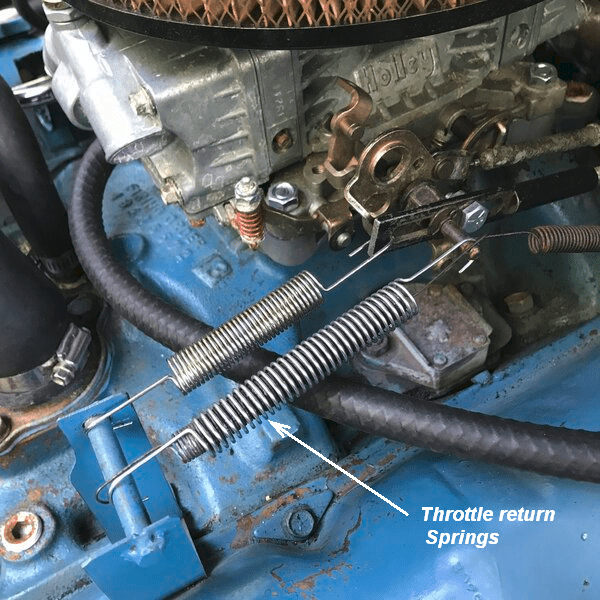

Throttle return springs will work correctly as attached.

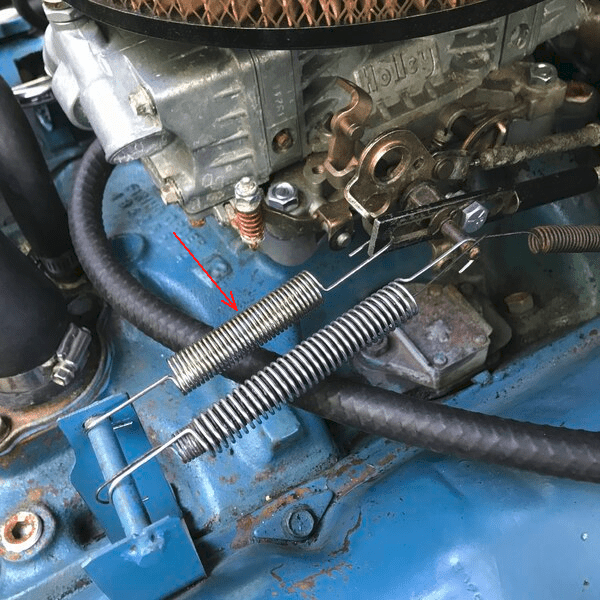

It does put some leverage on the stud that I personally see as a possible source of eventual failure.

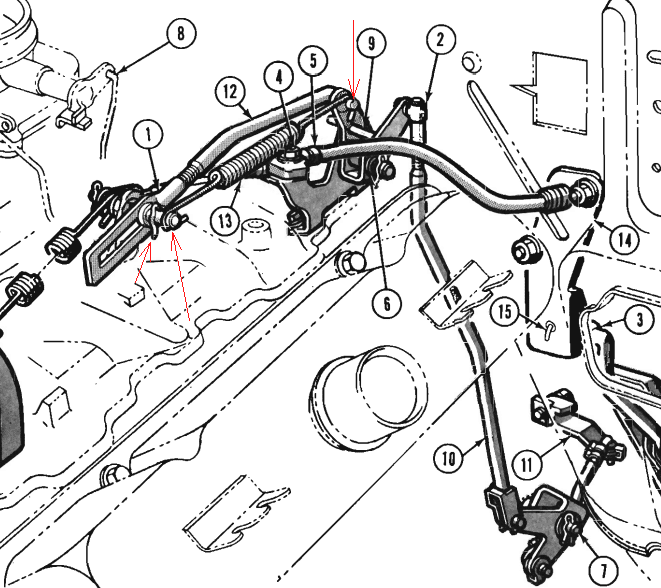

Transmission Linkage

These springs are incorrect and won't do the job.

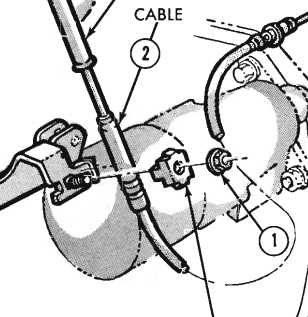

Both ends of the transmission linkage spring needs to move with the linkage.

This can be done as shown here in the 69 FSM, however there were other versions.

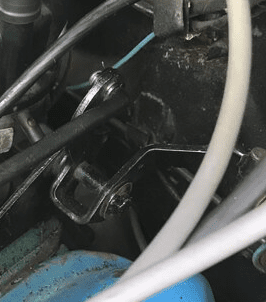

The hairpin clip and washer to ensure the adjustable rod doesn't slip off looks fine.

How well bellcrank will work with the rods I can't say.

The rod angles look about correct. The trick is to have correct matching bell crank ratios, and rod ends are roughly tangent to the arc in which they move.

What you see in posts 8 & 10 is correct.

The Chrysler video shows the correct method of adjustment. You can read and see the details by going to the booklet here,

Master Technician Service Conference - Chrysler's Training for Mechanics , under 1971.

Some of what pearljam posted is incorrect. Yes passing gear is simply the downshift. However it can be 2nd to 1st, 3rd to 2nd etc.

Later torqueflites were designed for 'part throttle' downshift.

Some clever bracketing you've done.

Throttle. My suggestion is to reorient the hold down clamp so it looks like the show manual shows. This provides more leverage so will hold the cable housing more securely.

Tip. Have a friend help to ensure the throttle is actual completely open when the pedal is floored. No more, no less.

Throttle return springs will work correctly as attached.

It does put some leverage on the stud that I personally see as a possible source of eventual failure.

Transmission Linkage

These springs are incorrect and won't do the job.

Both ends of the transmission linkage spring needs to move with the linkage.

This can be done as shown here in the 69 FSM, however there were other versions.

The hairpin clip and washer to ensure the adjustable rod doesn't slip off looks fine.

How well bellcrank will work with the rods I can't say.

The rod angles look about correct. The trick is to have correct matching bell crank ratios, and rod ends are roughly tangent to the arc in which they move.