Dead old 750 Holley - Resurrected !

So a good friend of mine brings me and old 4779 Holley 750 DP, and says, "fix it! F$%@# thing won't run". "Idles fat, and there's no adjustability on the mixture screws.

"See if you can get it to flow better, while you're at.. OK?"

Like many of you have seen before, and probably know why it don't F$%@# run.

So I do a quick Inspec to see if it had been monkeyed with in it's life.. (monkeys like to do that..) and all of the numbers appear to match! Good!

Air bleeds appear to be OE.. A quick reference of my book confirms.

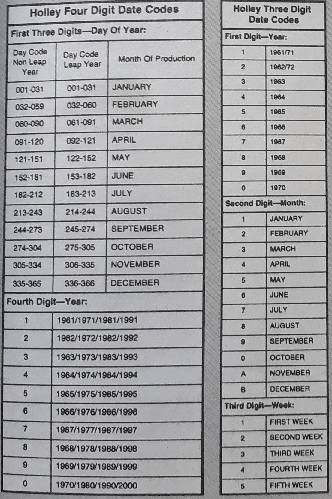

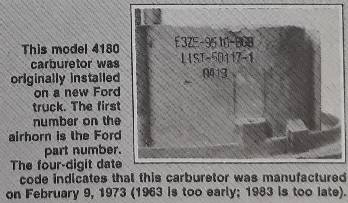

BTW, here's a cool tool to date your carb by using the code BELOW your List Number:

Looks like this carbs birthday is Sept 25 1973 (2693)

A quick flow test show's it flows 834 cfm. Pretty good! this model has the Down-Leg boosters, which I've found to flow about 40 cfm better than traditional boosters. So this is right in line with previous findings. A 650 will typically flow a tick over 700 cfm, stock and nearly 750 with modified Down-Legs installed.

I get it apart and run a file along the body/block mating surface. Bingo! it's warped.

Since I'm fairly confidant this is the issue for the complaint, I figured I'd go for more CFM !

It's a pretty common practice to bolt an 850 baseplate to the 750 body for more flow, but those aren't as easy to come by, so the next best thing is to thin the throttle shafts and replace the OE shaft screws with button head screws.

But before we take out these 'steaked-in' screws, lets remove that part of the screw with:

A 5/64" piloted drill.

A 5/64" piloted drill.

Sorry for the blurry pic, I was on my 3rd cup of coffee. As you can see, the pilot on the drill will center on the 'steaked' screw. Just take it down to the level of the shaft, like so.

Sorry for the blurry pic, I was on my 3rd cup of coffee. As you can see, the pilot on the drill will center on the 'steaked' screw. Just take it down to the level of the shaft, like so.

Most of you will say, "NO, DUH" to this, but I'm never surprised to see screw slots nearly stripped. So always use the right tool for the job. The bit should fit the screw and hold it like this:

NOTE: the throttle blades are numbered on the bottom side. Write down this orientation for reassembly. Or, you can number them with an arrow fwd.

This is interesting.. looks like a lot of fuel was indeed going through the carb. look at the cleaned area below the throttle blades. Also the witness mark where the blades used to ride.

Remove the choke lever off of the throttle shaft, pull back the shaft spring, and pull the shaft out.

When I pulled the shaft out of the baseplate, I noticed another common problem with old carbs.. the throttle lever is loose on the shaft. You can see the dark area, where the shaft has been working loose here: at the end of my pick.

I've got the shaft through a thick square bar with a hole in it. Just center punch the edges like this. Good as new!

TO BE CONTINUED

So a good friend of mine brings me and old 4779 Holley 750 DP, and says, "fix it! F$%@# thing won't run". "Idles fat, and there's no adjustability on the mixture screws.

"See if you can get it to flow better, while you're at.. OK?"

Like many of you have seen before, and probably know why it don't F$%@# run.

So I do a quick Inspec to see if it had been monkeyed with in it's life.. (monkeys like to do that..) and all of the numbers appear to match! Good!

Air bleeds appear to be OE.. A quick reference of my book confirms.

BTW, here's a cool tool to date your carb by using the code BELOW your List Number:

Looks like this carbs birthday is Sept 25 1973 (2693)

A quick flow test show's it flows 834 cfm. Pretty good! this model has the Down-Leg boosters, which I've found to flow about 40 cfm better than traditional boosters. So this is right in line with previous findings. A 650 will typically flow a tick over 700 cfm, stock and nearly 750 with modified Down-Legs installed.

I get it apart and run a file along the body/block mating surface. Bingo! it's warped.

Since I'm fairly confidant this is the issue for the complaint, I figured I'd go for more CFM !

It's a pretty common practice to bolt an 850 baseplate to the 750 body for more flow, but those aren't as easy to come by, so the next best thing is to thin the throttle shafts and replace the OE shaft screws with button head screws.

But before we take out these 'steaked-in' screws, lets remove that part of the screw with:

Most of you will say, "NO, DUH" to this, but I'm never surprised to see screw slots nearly stripped. So always use the right tool for the job. The bit should fit the screw and hold it like this:

NOTE: the throttle blades are numbered on the bottom side. Write down this orientation for reassembly. Or, you can number them with an arrow fwd.

This is interesting.. looks like a lot of fuel was indeed going through the carb. look at the cleaned area below the throttle blades. Also the witness mark where the blades used to ride.

Remove the choke lever off of the throttle shaft, pull back the shaft spring, and pull the shaft out.

When I pulled the shaft out of the baseplate, I noticed another common problem with old carbs.. the throttle lever is loose on the shaft. You can see the dark area, where the shaft has been working loose here: at the end of my pick.

I've got the shaft through a thick square bar with a hole in it. Just center punch the edges like this. Good as new!

TO BE CONTINUED