1968 340 timing

Lets explain why the '68 340 timing spec is 5* BTDC with some graphics.

Short version: It's a part of a package of changes to reduce the emission of HC and CO at idle. For it to work correctly, the rest of the package has to be used. Then it will be 'ok'. It won't work well if there ares changes to the cam, to the advance curve, to the idle fuel mix, or to the idle rpm used for setting the initial timing.

Chrysler explained this in their Master Tech Series, on this page 1967 Chrysler Imperial CAP System from the Master Technicians Service Conference Session 241, 1967 Chrysler Imperial Engine Combustion fom the Master Technicians Service Conference Session 240

Long version:

For best fuel economy and power at idle rpms the fuel-air mixture should usually be relatively rich, between 12:1 to a little more then 13:1 air to fuel.

The timing that best matches the mixture at idle speed is that provides the time (in fractions of a second) to get the best leverage on the crank.

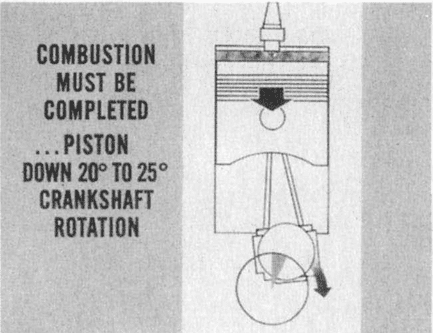

To reduce the carbon monoxide at idle and deceleration, timing at idle was delayed.

The results is more of the cylinder walls being exposed to the flame resulting in hotter combustion conditions and more thorough burning of the fuel components.

The slight loss in power was covered by slightly higher idle speeds.

Above idle rpm, timing was advanced very quickly so it would be virually the same as a non-emissions engine.

Unfortunely 340s were never released in a non-CAP version, so we can't compare directly. But we can look at other Chrysler hi-perf engine packages that had non-CAP and CAP versions.

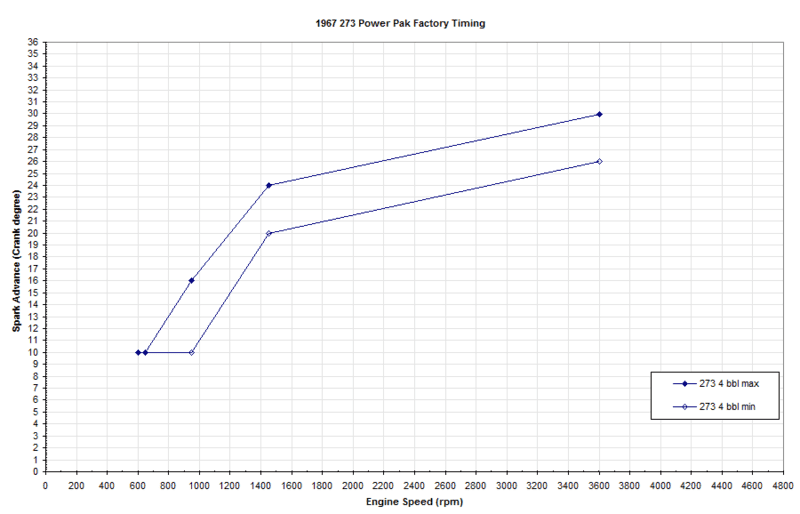

So lets look at timing for 1967 273 Power-Pak using specs from the Plymouth FSM.

This is the range of acceptable timing when initial was set to the target 10* at 600 to 625 rpm.

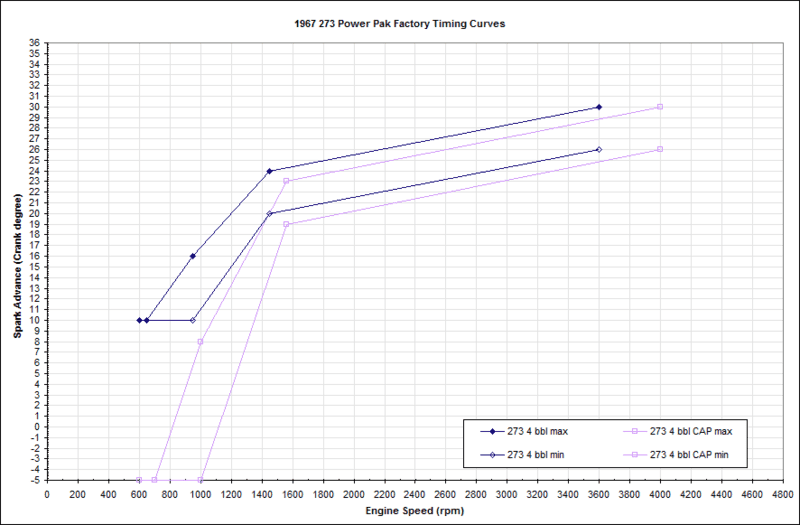

And now overlaying the timing for the same engine CAP equiped with a manual transmission.

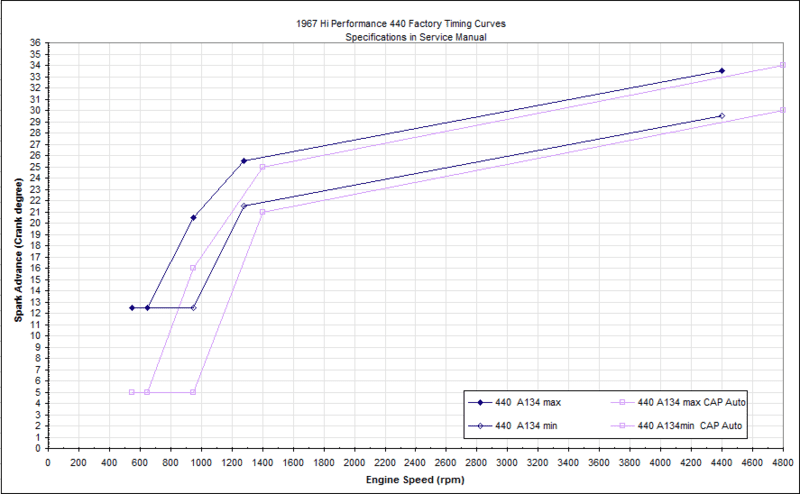

And here's an overlay of a '67 440 4bbl non CAP an dCAP with Automatic transmission.

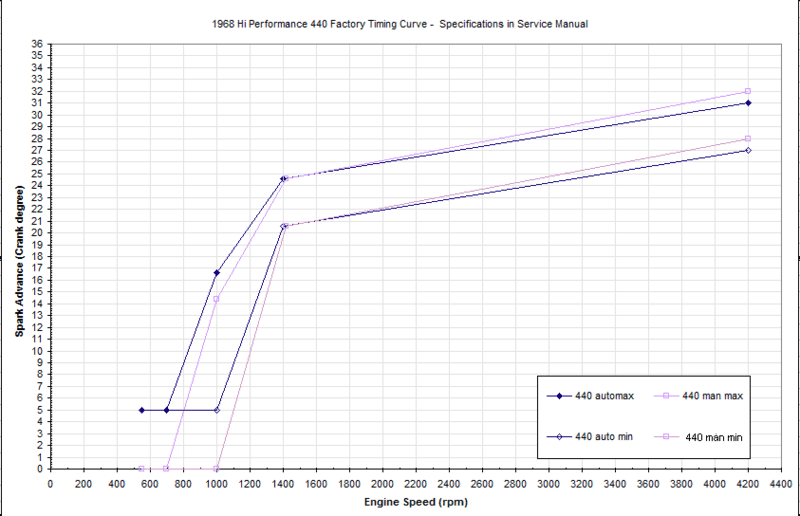

Getting to 1968, here's the 440 CAP timings

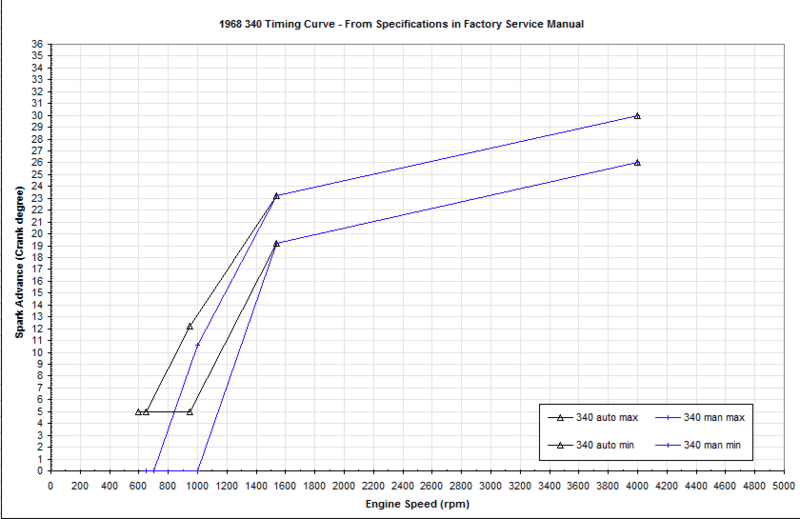

Now looking at the 340, we can see how the 5* initial worked with the matching distributor, when set at 625-650 rpm.

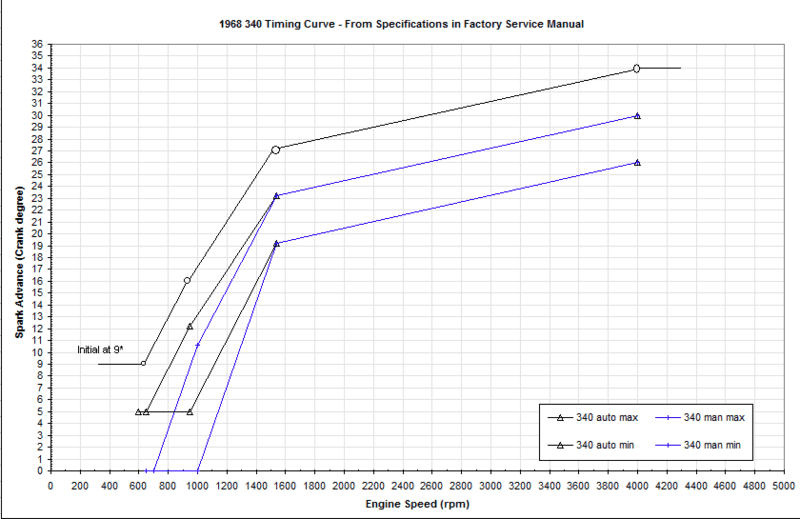

We can also see Plymouth was relatively conservative with the timing in general. This probably was done to ensure there would be no pinging under any conditions, location, or fuel. So even with an original distributor advance, you could experiment with additional initial timing. For example if the distributor advance rate was near the maximum, setting initial 9* at 650 RPM would result in a 34* at 4000 rpm, WOT. That's not unreasonable. In fact its typical starting point for performance tuning the timing.

Lets explain why the '68 340 timing spec is 5* BTDC with some graphics.

Short version: It's a part of a package of changes to reduce the emission of HC and CO at idle. For it to work correctly, the rest of the package has to be used. Then it will be 'ok'. It won't work well if there ares changes to the cam, to the advance curve, to the idle fuel mix, or to the idle rpm used for setting the initial timing.

Chrysler explained this in their Master Tech Series, on this page 1967 Chrysler Imperial CAP System from the Master Technicians Service Conference Session 241, 1967 Chrysler Imperial Engine Combustion fom the Master Technicians Service Conference Session 240

Long version:

For best fuel economy and power at idle rpms the fuel-air mixture should usually be relatively rich, between 12:1 to a little more then 13:1 air to fuel.

The timing that best matches the mixture at idle speed is that provides the time (in fractions of a second) to get the best leverage on the crank.

To reduce the carbon monoxide at idle and deceleration, timing at idle was delayed.

The results is more of the cylinder walls being exposed to the flame resulting in hotter combustion conditions and more thorough burning of the fuel components.

The slight loss in power was covered by slightly higher idle speeds.

Above idle rpm, timing was advanced very quickly so it would be virually the same as a non-emissions engine.

Unfortunely 340s were never released in a non-CAP version, so we can't compare directly. But we can look at other Chrysler hi-perf engine packages that had non-CAP and CAP versions.

So lets look at timing for 1967 273 Power-Pak using specs from the Plymouth FSM.

This is the range of acceptable timing when initial was set to the target 10* at 600 to 625 rpm.

And now overlaying the timing for the same engine CAP equiped with a manual transmission.

And here's an overlay of a '67 440 4bbl non CAP an dCAP with Automatic transmission.

Getting to 1968, here's the 440 CAP timings

Now looking at the 340, we can see how the 5* initial worked with the matching distributor, when set at 625-650 rpm.

We can also see Plymouth was relatively conservative with the timing in general. This probably was done to ensure there would be no pinging under any conditions, location, or fuel. So even with an original distributor advance, you could experiment with additional initial timing. For example if the distributor advance rate was near the maximum, setting initial 9* at 650 RPM would result in a 34* at 4000 rpm, WOT. That's not unreasonable. In fact its typical starting point for performance tuning the timing.