Run electric fans all the time?

I asked CVF Racing about their aluminum pulleys and this is what they said:

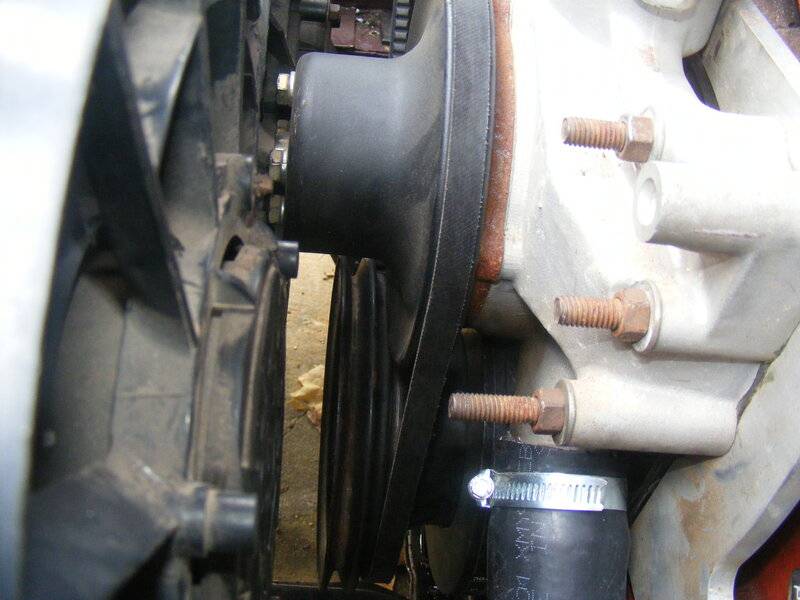

I looked at the stamped steel pulleys on there now, and the two rims are just about touching. The outer groove is for PS pump which I don't have. So the (inner) crank pulley would have to get bigger at the same time the water pump pulley gets smaller... Not only that, the water pump pulley can't get very much smaller either before hitting the pump bolts on its

ID.

Now what? :realcrazy:

I asked CVF Racing about their aluminum pulleys and this is what they said:

I looked at the stamped steel pulleys on there now, and the two rims are just about touching. The outer groove is for PS pump which I don't have. So the (inner) crank pulley would have to get bigger at the same time the water pump pulley gets smaller... Not only that, the water pump pulley can't get very much smaller either before hitting the pump bolts on its

ID.

Now what? :realcrazy: