You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Run electric fans all the time?

- Thread starter DrCharles

- Start date

-

DrCharles

Well-Known Member

Since I have a big-block (low deck) that won't be a problem

Now if I could only locate such a pulley!

Now if I could only locate such a pulley!

yellow rose

Overnight Sensation

I'm certainly willing to try a faster WP speed since that is relatively easy to do (compared to a new radiator), although I'm a bit wary of 30 or 40% overdrive... Not worried about throwing the belt, but of cavitation in the pump.

Today I've been searching for a pair of single-groove pulleys with faster than 0.95 ratio, but haven't been able to find anything either aftermarket or "pre-owned". The new ones are all "performance ratio" which is the exact opposite of what I'm looking for...

Honestly, I can’t remember what the discussion was on cavitation but whatever it was, there wasn’t much concern about it. It’s easy to pick up the phone tomorrow and call Evans and Stewart Components and talk to them about cavitation.

BTW, I chose those two companies because I switched to Evans coolant (I will no longer use anything else because of what that product does about system pressure...that alone is a big deal to me) and I wanted to make sure I was capable of running 11.25:1 on pump gas (I’m now at 11.77:1 when it goes back together) and not running it into detonation.

I called Steward Components because I use their thermostats and they make water pumps and other stuff for cooling systems.

Between the two, I did my cooling system. BTW, both said if you can get the fan close enough to the radiator to NOT use a shroud. Which I was already planning on not using a shroud.

yellow rose

Overnight Sensation

Since I have a big-block (low deck) that won't be a problem

Now if I could only locate such a pulley!

The only system I’ve found with enough over drive is a serpentine system from...damn...I can’t think of the place right now, but they are 14-15% over IIRC.

I’ll see if I can remember who that was...maybe it was CFV.

DrCharles

Well-Known Member

BTW, both said if you can get the fan close enough to the radiator to NOT use a shroud

My problem is getting the fan FAR enough from the radiator ;) I assume they're talking about mechanical fans, not electrical?

There might be room for the shortest fan clutch if I can find a solid fan that doesn't extend toward the core very far if at all. Otherwise I'd be stuck using a flex fan. For now I'd like to keep the Contour fans and see if I can make them work.

famous bob

mopar misfit

I'm certainly willing to try a faster WP speed since that is relatively easy to do (compared to a new radiator), although I'm a bit wary of 30 or 40% overdrive... Not worried about throwing the belt, but of cavitation in the pump.

Today I've been searching for a pair of single-groove pulleys with faster than 0.95 ratio, but haven't been able to find anything either aftermarket or "pre-owned". The new ones are all "performance ratio" which is the exact opposite of what I'm looking for...

Up a few posts , u said u didnt have a cooling problem , then why are u messing with it ??!

yellow rose

Overnight Sensation

My problem is getting the fan FAR enough from the radiator ;) I assume they're talking about mechanical fans, not electrical?

There might be room for the shortest fan clutch if I can find a solid fan that doesn't extend toward the core very far if at all. Otherwise I'd be stuck using a flex fan. For now I'd like to keep the Contour fans and see if I can make them work.

I’d even skip the clutch fan. It won’t matter. I use a stainless steel fix blade fan. IIRC it’s about .750 from the core. No shroud.

That big assed clutch fan just makes it tougher to get all that crap in there, and won’t cool any better than a decent fix blade fan.

DrCharles

Well-Known Member

Agreed, the fixed fan is the best cooler - but also consumes the most hp. I take it you are not a fan (pun intended) of flex fans?

Because I can never leave well enough alone

Up a few posts , u said u didnt have a cooling problem , then why are u messing with it ??!

Because I can never leave well enough alone

yellow rose

Overnight Sensation

Agreed, the fixed fan is the best cooler - but also consumes the most hp. I take it you are not a fan (pun intended) of flex fans?

Because I can never leave well enough alone

The HP loss from a fixed blade fan is made up at least in making more power controlling engine temperature.

I’ve said it many times on here, and why guys still argue the fact, that cooler engine temps make more power, every time.

Engine oils are so much better than they were in the 80’s and 90’s that it’s comical. So engine wear is a non issue IF you fix the tune up for cooler engine temps.

I wouldn’t worry about the few HP you give up with a fixed blade fan an get the engine temp down to 180 or less and make the power up and then some.

- Joined

- Apr 18, 2009

- Messages

- 4,300

- Reaction score

- 4,884

That’s not quite right. The hotter you can run an engine, the more power it will make, to a degree. Meaning if it gets too hot, bad things can/will happen.

Look at drag racing for a moment. Top Fuel, the longer they sit at the light, the more power they make due to the heat. That’s why, sometimes, they blow off the tires(smoke show). The game is played at the staging, ya hear about it all the time.

Look at drag racing for a moment. Top Fuel, the longer they sit at the light, the more power they make due to the heat. That’s why, sometimes, they blow off the tires(smoke show). The game is played at the staging, ya hear about it all the time.

yellow rose

Overnight Sensation

That’s not quite right. The hotter you can run an engine, the more power it will make, to a degree. Meaning if it gets too hot, bad things can/will happen.

Look at drag racing for a moment. Top Fuel, the longer they sit at the light, the more power they make due to the heat. That’s why, sometimes, they blow off the tires(smoke show). The game is played at the staging, ya hear about it all the time.

You sir, are DEAD wrong. The OP is NOT burning fuel. He’s on gasoline.

Maybe some time spend on the dyno to get the results and then to the track to prove them would help you.

Lower coolant temps make more power. Period. How is this even questioned any more?

DrCharles

Well-Known Member

I asked CVF Racing about their aluminum pulleys and this is what they said:

I looked at the stamped steel pulleys on there now, and the two rims are just about touching. The outer groove is for PS pump which I don't have. So the (inner) crank pulley would have to get bigger at the same time the water pump pulley gets smaller... Not only that, the water pump pulley can't get very much smaller either before hitting the pump bolts on its

ID.

Now what?

With aluminum pulleys you can only make the water pump pulley neck down to about 6.9" before it comes in contact with the bolts that hold the pump into the housing. With that being said, now you can only make the crank about 6.4" before it becomes too big and touches the water pump pulley. So the best ratio you're probably going to find is about 0.92:1. And we only do that combination with a two groove crank. Our single groove crank stuff is all underdriven because they are typically high horsepower race applications and aren't concerned with cooling or charging.

I looked at the stamped steel pulleys on there now, and the two rims are just about touching. The outer groove is for PS pump which I don't have. So the (inner) crank pulley would have to get bigger at the same time the water pump pulley gets smaller... Not only that, the water pump pulley can't get very much smaller either before hitting the pump bolts on its

ID.

Now what?

Last edited:

- Joined

- Apr 18, 2009

- Messages

- 4,300

- Reaction score

- 4,884

The Verdict: Hotter engines make more power. Sure, cooler air and fuel is denser, meaning more of it can fill combustion chambers to make more power, but once detonated, less energy (heat, in this case) being absorbed by engine material and coolant means more of it can be put toward forward motion.Nov 30, 2009

yellow rose

Overnight Sensation

The Verdict: Hotter engines make more power. Sure, cooler air and fuel is denser, meaning more of it can fill combustion chambers to make more power, but once detonated, less energy (heat, in this case) being absorbed by engine material and coolant means more of it can be put toward forward motion.Nov 30, 2009

Total and provable BULLSHIT. Believe it if you want, but you’ll still be wrong.

yellow rose

Overnight Sensation

I asked CVF Racing about their aluminum pulleys and this is what they said:

I looked at the stamped steel pulleys on there now, and the two rims are just about touching. The outer groove is for PS pump which I don't have. So the (inner) crank pulley would have to get bigger at the same time the water pump pulley gets smaller... Not only that, the water pump pulley can't get very much smaller either before hitting the pump bolts on its

ID.

Now what?

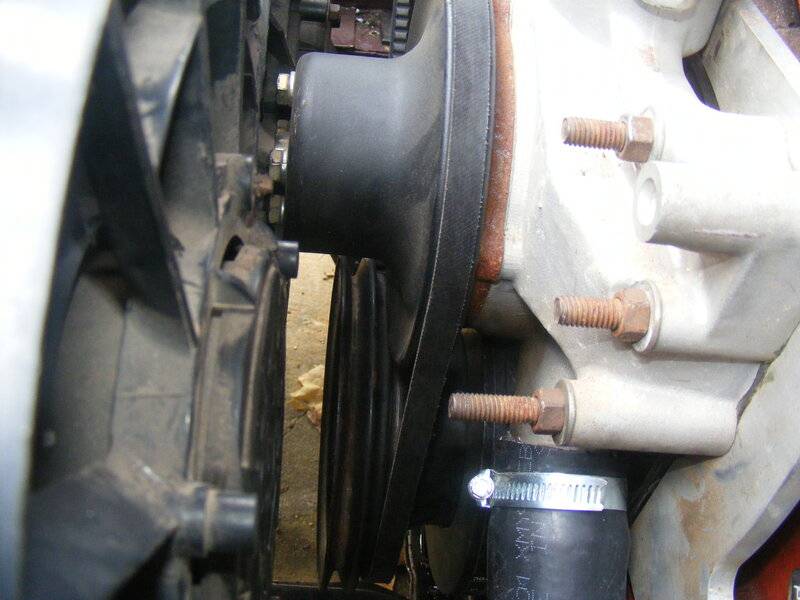

View attachment 1715595199

I’ll measure my pulleys when I get home, but they are overdriven.

Did you ask about the serpentine pulleys? Seems I called about them and they had a better ratio.

DrCharles

Well-Known Member

Hey guys... can you please start another thread debating this?

I just want to run my engine at 180-185.

And right now, need to know how to speed up the water pump (with a single belt, single groove setup if at all possible)...

I just want to run my engine at 180-185.

And right now, need to know how to speed up the water pump (with a single belt, single groove setup if at all possible)...

DrCharles

Well-Known Member

I’ll measure my pulleys when I get home, but they are overdriven.

Did you ask about the serpentine pulleys? Seems I called about them and they had a better ratio.

A pic of a working, big-block pulley setup would be great

I am not interested in putting all that serpentine stuff on my engine - nor spending the $ it would cost, thanks.

famous bob

mopar misfit

Agreed, the fixed fan is the best cooler - but also consumes the most hp. I take it you are not a fan (pun intended) of flex fans?

Because I can never leave well enough alone

Same here to an extent , refining my set up now , trying to make it better/faster . Cooling problem appears to be whipped , still have a 7 blade 17 1/2'' fan to try if the need arises next summer m, running this 6 blade 17'' now.

yellow rose

Overnight Sensation

A pic of a working, big-block pulley setup would be great

I am not interested in putting all that serpentine stuff on my engine - nor spending the $ it would cost, thanks.

I just called and asked. The serpentine system is 18% OVERdriven.

It’s only 345 bucks to convert if you just run an alternator. I wish I had done that when I bought my set up.

So my pulleys will be up for sale as I’m switching if that’s the only way to get the pump speed up.

A FWIW...any stooge can walk through the pits at any National Event and see all the Pro Stock, all the Comp Eliminator cars chilling their engines before every pass.

They must be the dumbest bastards on the planet to piss away power like that.

The fact is, again, for the umpteenth time, lower coolant temps make more power.

How low you can get depends on several factors, the biggest for guys driving their stuff around is at what temp does the heater become ineffective.

Other than that, the lower the coolant temp, the more power you can make.

DrCharles

Well-Known Member

The only factory pulley setup (from Bouchillon) I can find that will work is:

4-groove crank pulley (outer 2 grooves are 7") BPE4013

2-groove WP pulley (5-7/8") BPE4016

(and would have to relocate the alternator forwards to line up with the third groove).

But that gives a 7/5.875 = 1.19:1 ratio which might work.

I could make a spacer to relocate my existing 2-groove (or buy a single-groove) crank pulley forwards to line up with the 5-7/8" 2-groove WP pulley. Still have to space the alternator, too.

Stock crank groove is 6-9/16", resulting in 6.5625/5.875 = 1.12:1, maybe even better for my application.

Thoughts? ;)

4-groove crank pulley (outer 2 grooves are 7") BPE4013

2-groove WP pulley (5-7/8") BPE4016

(and would have to relocate the alternator forwards to line up with the third groove).

But that gives a 7/5.875 = 1.19:1 ratio which might work.

I could make a spacer to relocate my existing 2-groove (or buy a single-groove) crank pulley forwards to line up with the 5-7/8" 2-groove WP pulley. Still have to space the alternator, too.

Stock crank groove is 6-9/16", resulting in 6.5625/5.875 = 1.12:1, maybe even better for my application.

Thoughts? ;)

DrCharles

Well-Known Member

So my pulleys will be up for sale as I’m switching if that’s the only way to get the pump speed up.

Refresh my memory, what are you running right now (and what accessories)?

$345 isn't too bad. Will look at it, but I bet there are idlers and tensioners all over the place. The single V-belt has: alternator bracket, WP pulley, crank pulley. That's it!

DrCharles

Well-Known Member

CVF says their basic serpentine conversion is 0.92:1 underdrive. No good.

A 3-groove crank pulley (using the outer groove) and a 2-groove a/c WP pulley (using the inner groove) supposedly will line up. Alternator will need remounting. The problem is that the belt will be running very close to the Contour fan shroud since it'll be a lot further forward. So the faster water pump is not proving very practical in the limited A-body space.

I'm going to install a PWM controller and see if I can keep the temps cooler in the first place (no point in letting it get to 198 before the fans come on).

A 3-groove crank pulley (using the outer groove) and a 2-groove a/c WP pulley (using the inner groove) supposedly will line up. Alternator will need remounting. The problem is that the belt will be running very close to the Contour fan shroud since it'll be a lot further forward. So the faster water pump is not proving very practical in the limited A-body space.

I'm going to install a PWM controller and see if I can keep the temps cooler in the first place (no point in letting it get to 198 before the fans come on).

yellow rose

Overnight Sensation

CVF says their basic serpentine conversion is 0.92:1 underdrive. No good.

A 3-groove crank pulley (using the outer groove) and a 2-groove a/c WP pulley (using the inner groove) supposedly will line up. Alternator will need remounting. The problem is that the belt will be running very close to the Contour fan shroud since it'll be a lot further forward. So the faster water pump is not proving very practical in the limited A-body space.

I'm going to install a PWM controller and see if I can keep the temps cooler in the first place (no point in letting it get to 198 before the fans come on).

WTH?? They really said that? I actually called them and I wrote down the pulley diameters for the serpentine system. The crank is 6.4 inches and the water pump is 5.4 inches which is a skosh over 18% overdriven.

I won’t be home until Wednesday afternoon but when I get there, I can pull the receipt for the pulleys I now have. IIRC I ended up with a crank pulley they have listed as a big block part or it was the water pump pulley, I forget which.

Like I said...when I did mine, I didn’t want the serpentine system either. Since I only need 1 groove everything, I didn’t think it was a big deal. Now, I’m spending twice, which I hate doing to get the water pump speed where I want it.

I’ll let you know Wednesday what the part numbers are of the pulleys I have.

DrCharles

Well-Known Member

WTH?? They really said that? I actually called them and I wrote down the pulley diameters for the serpentine system. The crank is 6.4 inches and the water pump is 5.4 inches which is a skosh over 18% overdriven.

Yes.

That one is going to be slightly underdriven but not by much. It runs about 0.92:1

Look at the picture... no way is that WP pulley smaller than their standard 6.4" crank pulley.

Big Block Chrysler Serpentine Conversion, Alternator Only

-