HEADS UP

I have been finishing up a magnum block build with edelbrock LA heads this week. I just thought I would share this for anyone doing a similar build.

I put the heads on to check pushrod and piston to valve clearance with a couple of hyd roller lifters that I made solid for checking.

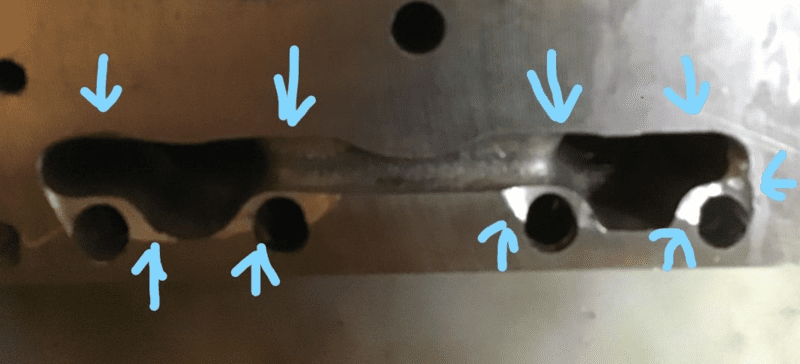

I found that with the edelbrock LA heads, the magnum roller lifters were too tall to able to be removed with the heads on. I had to grind clearance notches in the heads so that they can come out. The grinding at the top arrows is more than it appears in the picture.

With the notches the lifters can now go in and out with the heads on. I had milled this block only .012, and the head gaskets were the .051 thick 8553 felpros.

Also, this motor is using 273 adjustable rockers. I tubed the intake pushrod and head bolt holes in the heads for porting.

I anticipated needing more room, so I used 9/16 tubes for the pushrod holes instead of 17/32.

I still had to grind a lot to get the pushrods to clear on the bottom side of the head. I had to cut the far side of the holes (The farthest part of the hole away from the cam) a good bit.

I had to grind out the brass tube on the back side up about 600 thousandths. This was with 5/16 pushrods.

This should be a nice street motor, KB pistons .018 out of the hole, a tad over 11:1 compression. Lunati Hyd roller 296, 304 adv. 243, 251 @.050, 560" 565", 110

I have been finishing up a magnum block build with edelbrock LA heads this week. I just thought I would share this for anyone doing a similar build.

I put the heads on to check pushrod and piston to valve clearance with a couple of hyd roller lifters that I made solid for checking.

I found that with the edelbrock LA heads, the magnum roller lifters were too tall to able to be removed with the heads on. I had to grind clearance notches in the heads so that they can come out. The grinding at the top arrows is more than it appears in the picture.

With the notches the lifters can now go in and out with the heads on. I had milled this block only .012, and the head gaskets were the .051 thick 8553 felpros.

Also, this motor is using 273 adjustable rockers. I tubed the intake pushrod and head bolt holes in the heads for porting.

I anticipated needing more room, so I used 9/16 tubes for the pushrod holes instead of 17/32.

I still had to grind a lot to get the pushrods to clear on the bottom side of the head. I had to cut the far side of the holes (The farthest part of the hole away from the cam) a good bit.

I had to grind out the brass tube on the back side up about 600 thousandths. This was with 5/16 pushrods.

This should be a nice street motor, KB pistons .018 out of the hole, a tad over 11:1 compression. Lunati Hyd roller 296, 304 adv. 243, 251 @.050, 560" 565", 110