Fuel Gauge Inop

You need to treat the gauges as a SYSTEM. Do the other gauges work? If so, you can "sort of temporarily" eliminate some of the system

You evidently have a second sender that is out of a tank? If so you can use that as your test device.............

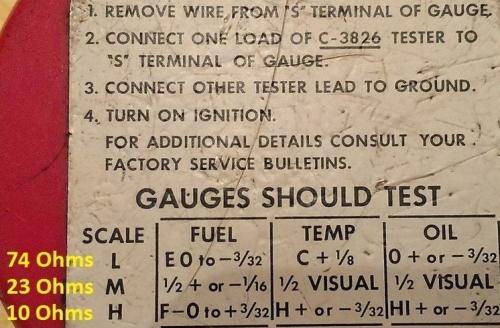

The photo below is a third party gauge tester that mimicks the factory one depicted in the service manual. If you do NOT have a service manual you need to wander over to MyMopar and download one.......free

Notice the yellow resistance readings. Someone created this edited photo, thank you whoever that was!!! Anyhow notice the 3 readings. you can take your gas sender and use your ohmeter to adjust it to either the middle or high reading, then hook it to the temp gauge wire, turn on the key, and verify that the temp gauge goes to that reading. This proves the "rest of" the system works (the IVR, etc) and that your concept is sound.

If this happens, connect your test device.......adjusted for the same as above......to the fuel sender wire. It should drive the gauge to same reading

==================================================

If the above test "passes" then it must be something to do with the sender in the tank. Start by measuring the sender resistance as installed in the tank, putting your probes onto the SENDER flange and the sender wire terminal. If you have the proper "empty" reading, then of course connecting to the gauge should indicate that

IF NOT, now leave the key 'in run' and stab your probe onto a GOOD body ground, making sure to stab through rust, etc. Now stab the remaining probe onto the sender flange. ANY voltage there means it is not truly grounded.

Next to confirm, pull the sender wire off. Perform same test with resistance. Meter should show zero or very close to zero.

=========================================================

When you reduce all the BS this is a fairly simple circuit. The functional path is:

Ignition switch........to PC board harness connector...........to IVR.........to gauge.........through gauge...........to harness connector.............sender wire down to left kick panel rear harness connector...........out to rear of car........to sender connector........through sender.......to ground

=============================================================

Common problems are loose pins on the PC board connector not making connection to pc board traces, bad connection at the IVR contacts to the board traces, and poor connections from the board traces to the gauge stud/ nuts. Gauge can be bad. Kick panel connector can be loose/ corroded, and SENDER END CONNECTOR can be damaged/ corroded inside the boot.

Sender can be poorly grounded. I would "do what it takes" to get a pigtail connected to the sender-------even if you solder one to say, the fuel nipple down low,.......and bolt the pigtail to a 'clean' point on the body

You need to treat the gauges as a SYSTEM. Do the other gauges work? If so, you can "sort of temporarily" eliminate some of the system

You evidently have a second sender that is out of a tank? If so you can use that as your test device.............

The photo below is a third party gauge tester that mimicks the factory one depicted in the service manual. If you do NOT have a service manual you need to wander over to MyMopar and download one.......free

Notice the yellow resistance readings. Someone created this edited photo, thank you whoever that was!!! Anyhow notice the 3 readings. you can take your gas sender and use your ohmeter to adjust it to either the middle or high reading, then hook it to the temp gauge wire, turn on the key, and verify that the temp gauge goes to that reading. This proves the "rest of" the system works (the IVR, etc) and that your concept is sound.

If this happens, connect your test device.......adjusted for the same as above......to the fuel sender wire. It should drive the gauge to same reading

==================================================

If the above test "passes" then it must be something to do with the sender in the tank. Start by measuring the sender resistance as installed in the tank, putting your probes onto the SENDER flange and the sender wire terminal. If you have the proper "empty" reading, then of course connecting to the gauge should indicate that

IF NOT, now leave the key 'in run' and stab your probe onto a GOOD body ground, making sure to stab through rust, etc. Now stab the remaining probe onto the sender flange. ANY voltage there means it is not truly grounded.

Next to confirm, pull the sender wire off. Perform same test with resistance. Meter should show zero or very close to zero.

=========================================================

When you reduce all the BS this is a fairly simple circuit. The functional path is:

Ignition switch........to PC board harness connector...........to IVR.........to gauge.........through gauge...........to harness connector.............sender wire down to left kick panel rear harness connector...........out to rear of car........to sender connector........through sender.......to ground

=============================================================

Common problems are loose pins on the PC board connector not making connection to pc board traces, bad connection at the IVR contacts to the board traces, and poor connections from the board traces to the gauge stud/ nuts. Gauge can be bad. Kick panel connector can be loose/ corroded, and SENDER END CONNECTOR can be damaged/ corroded inside the boot.

Sender can be poorly grounded. I would "do what it takes" to get a pigtail connected to the sender-------even if you solder one to say, the fuel nipple down low,.......and bolt the pigtail to a 'clean' point on the body