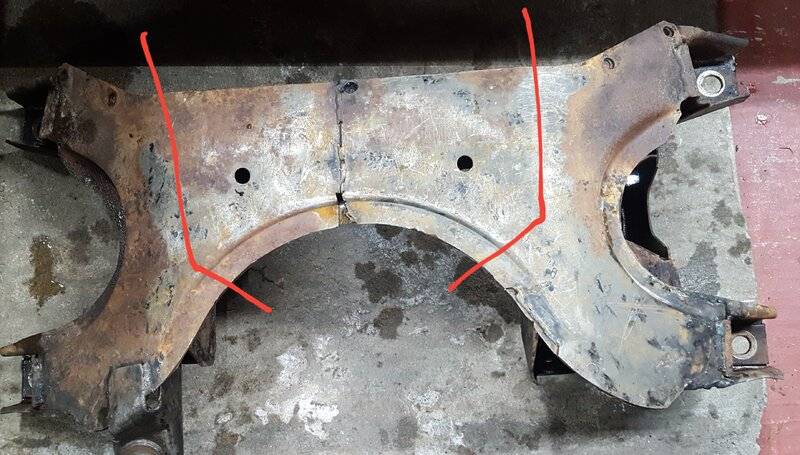

67 Big Block K-frame Reinforcement

I was also thinking that adding additional spot welds to the perimeter couldn't hurt, and found this on fbbo today:

B Body K member Best Upgrade

After considering a few things, cutting an access hole to weld the sleeves from the inside, adding additional spot welds around the perimeter on the bottom, possibly welding the seams, and dents in the bottom, which I pulled out slightly with a slide hammer through the bottom 2 holes, my brain asked -

How realistic it would be to separate the 2 bottom pieces completely?

It appears to be welded well in all 4 corners, and I don't want to remove the idler arm mount and screw it up.

I think the correct answer is address the sleeves by cutting access holes.

Then, see if I can cut the bottom out only where the dents are if there are not too many spot welds.

Add additional spot welds to the perimeter and call it done.

This isn't a track or race car, but it's out, all apart, and I'm putting in new suspension stuff.

Pics are before slide hammer, but even with the biggest washer I could get into the k-frame, and also working it with a steel dowel from the top holes, and a little heat, it's just too thick to move back into place.

Of course, what the heck do I know anyway.

I was also thinking that adding additional spot welds to the perimeter couldn't hurt, and found this on fbbo today:

B Body K member Best Upgrade

After considering a few things, cutting an access hole to weld the sleeves from the inside, adding additional spot welds around the perimeter on the bottom, possibly welding the seams, and dents in the bottom, which I pulled out slightly with a slide hammer through the bottom 2 holes, my brain asked -

How realistic it would be to separate the 2 bottom pieces completely?

It appears to be welded well in all 4 corners, and I don't want to remove the idler arm mount and screw it up.

I think the correct answer is address the sleeves by cutting access holes.

Then, see if I can cut the bottom out only where the dents are if there are not too many spot welds.

Add additional spot welds to the perimeter and call it done.

This isn't a track or race car, but it's out, all apart, and I'm putting in new suspension stuff.

Pics are before slide hammer, but even with the biggest washer I could get into the k-frame, and also working it with a steel dowel from the top holes, and a little heat, it's just too thick to move back into place.

Of course, what the heck do I know anyway.