You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Barracuda Notch 340

- Thread starter I8NEMO

- Start date

-

Waiting on fuel line and electrical harness so I dove into the motor shim generated air plenum modification, which is hard to accept since after all ofthat careful work the hood closed perfectly over the air cleaner from the get go. I had already determined how much I needed to trim from the right side of the plenums air cleaner hole and add to the left. I did this using a cardboard strip taped to the plenum jutting over the hole. With the air cleaner lid inverted, I used gray silicone dabbed onto the lids sharp edge and lowered the hood to get my mark. 11/16" minus my 3/16" gap equals 1/2" to trim off one side and add ro the other side, well I cut the side off and mocked it up with tape on the opposing side and lowered the hood and, not good. Too wide a cut so a big gap on one side and hitting air cleaner on the other side. I took the cut piece off and measured again, At least with the plenum clearing the air cleaner everywhere, I could shut the hood further and get a really good look, and another measurement- 5/16". So yesterday I glassed the cut piece back in its original position, today I'll cut again at 5/16"

More mocking up and hood opening and closing showed me a final measurement of 7/16" to cut from the right side and add to the left side. This worked perfect. The upside to the first attempt screw up is the entire hole perimeter now has 8 layers of epoxy/ fiberglass which significantly stiffened the entire piece. Made headway on new fuel tube saga. Stay tuned!

View attachment 1715634454 View attachment 1715634449 View attachment 1715634449 View attachment 1715634454 Fuel lines are done from pump to carb. The 4 row factory style radiator from Classic had no mounts for shroud so had my factory brackets soldered on to the new 4 row. My shroud from Mancini landed, got the radiator painted, shroud on, overflow done. Belt alignment on alternator was a little off so made a new spacer out of a cheap old deep socket. Im ready to break this motor in if I had the dash harness... still waiting.

View attachment 1715634449

View attachment 1715634453

View attachment 1715634449

View attachment 1715634453

Wiring in correct pigtails for 2014 Chally headlights and park/ turn signals. Welded in weld nuts for wiper bottle mount. Weird, I discovered 2 sets of mounting holes in the fender.

Still waiting on under dash harness to fire motor so keeping busy. I pulled the trigger on the 69 reverse lights so I have the socket and mount holes drilled. Next I'll fit up the housings and weld on weld nuts to the back of the valance.

Yeah, not that simple. Mustang lenses must be thicker, sockets were hitting valance so had to modify my socket holes, I didn't think the lenses would survive the belt sander with all the perimeter breaks. Once I had the housings exactly where I wanted them I Gorilla taped them in place. Free hand drilling the mounting screw holes was not fun but it worked. Cut down the weld nuts and got them welded in. 67/69 reverse lights on my 68 is now finished. Back to electrical tomorrow since my dealer only front 2014 Chally turn signal pigtails are in. $100 for both. Jeezuz,Weird, NAPA had the headlight pigtails for $18 a pc. That's Hot Rodding I guess.

Radiator spring clamps came in, we'll see if they leak. Reverse light gaskets landed. Got turn/park pigtails spliced soldered in today. Fan shroud bolts landed... now where's that damn back ordered dash harness.

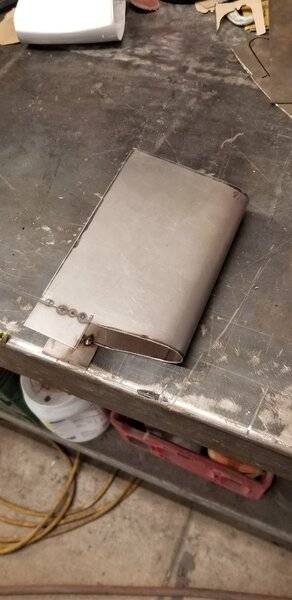

Still no dash harness but found a straggler project. Replace lower valance center piece mock up ( cut up painted armor all bottle) with steel piece.

Challngd73

Well-Known Member

That looks great. Nice work!Still no dash harness but found a straggler project. Replace lower valance center piece mock up ( cut up painted armor all bottle) with steel piece.

View attachment 1715649870

View attachment 1715649871

View attachment 1715649872

View attachment 1715649874

View attachment 1715649875

View attachment 1715649877

View attachment 1715649878

Your pictures will look better if you do this:

Much thanks!That looks great. Nice work!

Now that the nose piece is under the microscope, clearly the vertical core support needs some massaging. Pics don't really show it but the bottom of the nose piece needed to kick to passenger side. Looks right. Lastly I used stainless buttonhead screws to secure the nose piece to the support. Still no wiring harness.

Still waiting on b.o. wiring harness. Playing with an old idea. The hood is large and pretty flat, thought adding a3rd dimension would work. 3.5" quarter hemis on driver side, 4.5" hemis on passenger side, chopped down and " squished" . I don't have fancy tools, not even a band saw so this required hand held cuts on my old chop saw. Not bad for a mock up look. I like the 4.5" look

Topless69

Well-Known Member

2 things I’ve always wanted to do to an old Barracuda is make the hood inserts functional and the rear panel between the taillights one solid bar of light for the brake/running lights, or a squared oval running between the tail lights.

I like the mods you’re doing on yours - Following this build with great interest.

I like the mods you’re doing on yours - Following this build with great interest.

I think I'll move forward with this design idea in stainless so the entire assembly can be polished. Pretty sure these scoops will be removable as well. Here's pics with both sides completed in steel.

There is a Santa! Under dash harness landed so It's back to work y'all

Got my nose into all things electrical again, wired up new harness to instrument panel and installed this morning. My new fuse block has a blank right where the original had a dedicated fuse for tach, anyone know how critical this dedicated fuse is? It's not a dedicated circuit because the hot side is factory jumped from a neighboring fuse terminal. Had a lone unlabeled gray/ black wire in the parts tub, memory just couldn't kick in, then I got onto finding factory tach wires that aren't in the harness. Thankfully, my tear down pics showed the blue and gray/ black wires for the tach which saved some time. Ive gotta make bulk head connections, add oil and coolant, run through my checklist and I'll be ready to fire the motor, maybe this Saturday. Ive committed to a live start with friends so, if I missed something and it's a bust, we'll just drink more beer!

Yesterday was a milestone, got the 340 started in a big way but an inlet bowl fitting leak won the day. Brand new carb but I swapped in 5/16" fittings to accommodate the smaller tube nuts on the SS tubes factory looking dual feed kit. Today I reinstalled the 3/8" fittings with adapters to Male barbs and will run fuel hose for now. Waiting for ss tubes to respond on switching nut size to 3/8" . I will say the 15 seconds of run time really blew me away, this thing is one cam loping high strung pissed off small block. Maybe body and paint ain't that important, lol

Too bad video files are too big to share here.

Last Sunday had fuel leak resolved and moved fwd with cam break in. Got it done with an oil leak this time. Streaming out at 3k rpm so my guess is, oil filter plate. Got a Canton billet replacement coming. Also, after much searching for Magnum style t stat housings I went with a stamped pos only because I haven't had luck with o ring billet necks. Had to grind 2 nubs off the bottom of the pos, and yep it leaks. P.O.S. the gasket disintegrated, scraped it into mush with a fingernail. Going with a billet o ring job from JEGS next. What's another week right?

This is some of the best money I’ve spent on my Duster. Granted, this gasket is for the smaller LA t-stat. I couldn’t find one for a magnum so I bought a sheet of high temp silicone and cut out my own.

Thermostat Housing Gasket (SILICONE) MOPAR V-8 ENGINES - Part # RG-53063 | eBay

Thermostat Housing Gasket (SILICONE) MOPAR V-8 ENGINES - Part # RG-53063 | eBay

That outta last a long long time. Thanks for your info!This is some of the best money I’ve spent on my Duster. Granted, this gasket is for the smaller LA t-stat. I couldn’t find one for a magnum so I bought a sheet of high temp silicone and cut out my own.

Thermostat Housing Gasket (SILICONE) MOPAR V-8 ENGINES - Part # RG-53063 | eBay

Yeah I’ve had it on my engine for several years and had the thermostat housing off a few times, just clean the gasket up and put it back together, leak freeThat outta last a long long time. Thanks for your info!

-