A life's (fatal) lesson on how NOT to maintain magnetos

I ran across this guy when searching for info on the terrible air -to-air float plane crash this summer.

These videos deal with the tragic loss of the "was" gorgeous "909" B-17 and LOSS OF LIFE.

The last video shows some pretty bad examples of "how not to maintain" magnetos, whether your lawn mower, old OMC outboard, or A/G dragster.........or your "hobby" warbird

BEAR IN MIND that these guys GET YOU to donate money TO GO FOR A RIDE!!!

The last video first

The first video

In the following photos, investigators found BIG BIG problems with BOTH mags on the no4 engine.

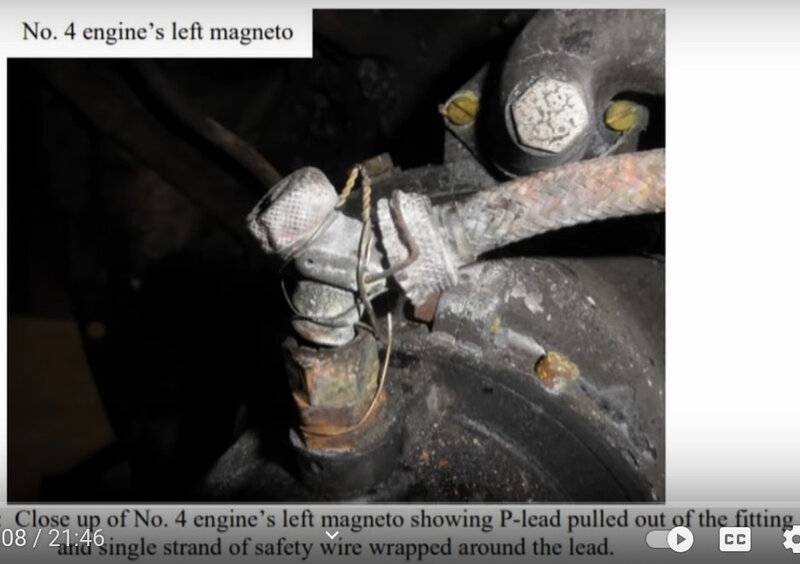

One "P lead" (primary lead) is pulled out of the left mag far enough that the "safety" grounding tab GROUNDED THE MAG, disabling that mag

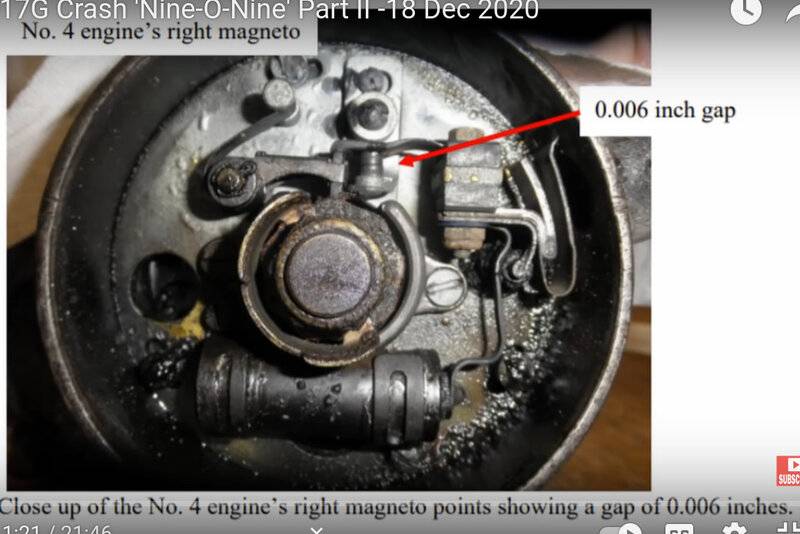

The points on the right mag WERE ONLY GAPPED at .006"

Additionally, investigators found weak condensers and coils on both mags, and one mag had the cam lobe worn below specs meaning that even if they had been "operating" the spark would have been marginal

In addition, plug gaps were excessive, and evidently required plug maintenance was lacking

First photo below is illustrating the "almost none" points gap on one mag. There are other problems

Below, "P lead" pulled out of mag. This lead goes to the "kill" switch in the cockpit and grounds/ kills the mag in "off." In this case a "safety" device engaged, killing the mag. The safety device is held off when the 'P lead' is properly inserted and installed

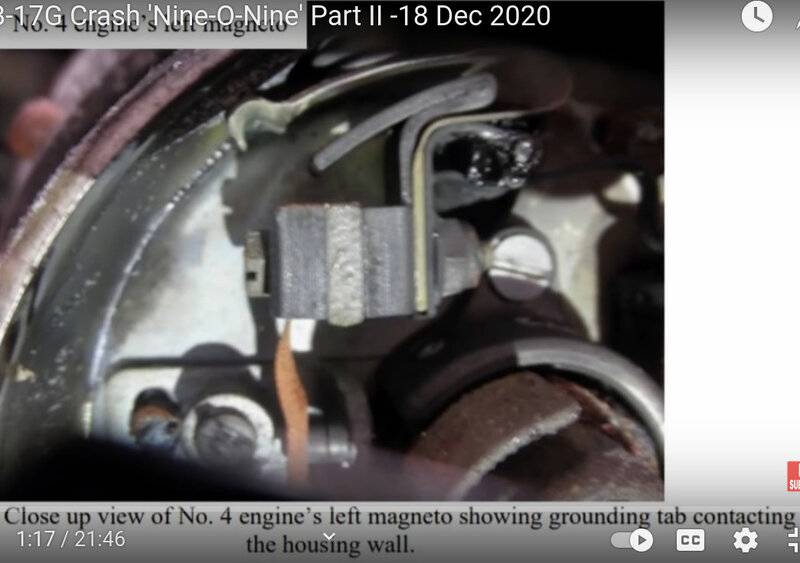

Below, this last photo showing the "safety" device which grounds the points if the "P lead" (primary lead) gets pulled out of the mag. The "safety" part is that the P lead grounds the mag to "kill" it just like on a lawn mower. You would not want to not be able to shut down an engine, right? But in this case it cause deterioration of engine performance because this mag quit working at some point, as the safety contact grounded it

I ran across this guy when searching for info on the terrible air -to-air float plane crash this summer.

These videos deal with the tragic loss of the "was" gorgeous "909" B-17 and LOSS OF LIFE.

The last video shows some pretty bad examples of "how not to maintain" magnetos, whether your lawn mower, old OMC outboard, or A/G dragster.........or your "hobby" warbird

BEAR IN MIND that these guys GET YOU to donate money TO GO FOR A RIDE!!!

The last video first

The first video

In the following photos, investigators found BIG BIG problems with BOTH mags on the no4 engine.

One "P lead" (primary lead) is pulled out of the left mag far enough that the "safety" grounding tab GROUNDED THE MAG, disabling that mag

The points on the right mag WERE ONLY GAPPED at .006"

Additionally, investigators found weak condensers and coils on both mags, and one mag had the cam lobe worn below specs meaning that even if they had been "operating" the spark would have been marginal

In addition, plug gaps were excessive, and evidently required plug maintenance was lacking

First photo below is illustrating the "almost none" points gap on one mag. There are other problems

Below, "P lead" pulled out of mag. This lead goes to the "kill" switch in the cockpit and grounds/ kills the mag in "off." In this case a "safety" device engaged, killing the mag. The safety device is held off when the 'P lead' is properly inserted and installed

Below, this last photo showing the "safety" device which grounds the points if the "P lead" (primary lead) gets pulled out of the mag. The "safety" part is that the P lead grounds the mag to "kill" it just like on a lawn mower. You would not want to not be able to shut down an engine, right? But in this case it cause deterioration of engine performance because this mag quit working at some point, as the safety contact grounded it