Speedmaster heads part 2. Plus intake work

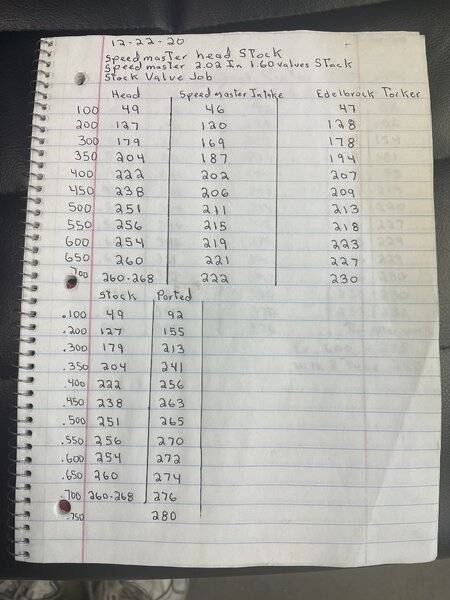

Ok some updated flow numbers and to say I’m happy would be an understatement. My whole mission was to give Ethan a good head but one that would shine with a cam under .550 lift, probably closer to .500 lift. One of the reasons I do this is to engage others and not only show what I can do but get ideas from others as I too learn something almost every time I port a head. Something I think Brian (OU812) said was in the back of my mind and here was the perfect chance to try it. He said if you don’t do chamber work the low lift numbers will be better. Hmmm perfect job to put that thinking to test. I removed some bad machine flashing left around one intake valve with a sanding roll. (Not the one I flow tested) I also relieved the spark plug holes (no affect on flow) and that was it, nothing more. I would have loved to added a 15 degree cut to the valve job but couldn’t because of the large 30 degree they cut. I added a 30 degree back cut to the speedmaster intake valves. I’m going to now retest the new speedmaster intake then port it but will start another port on that work. I have a few intakes I would like to test on this head. Ohhh I lapped in a couple of the valve jobs that came on the heads and if all look as good as those two they will go on his car that way. Seeing these numbers give me no reason to do a valve job.

all look as good as those two they will go on his car that way. Seeing these numbers give me no reason to do a valve job.

Ok some updated flow numbers and to say I’m happy would be an understatement. My whole mission was to give Ethan a good head but one that would shine with a cam under .550 lift, probably closer to .500 lift. One of the reasons I do this is to engage others and not only show what I can do but get ideas from others as I too learn something almost every time I port a head. Something I think Brian (OU812) said was in the back of my mind and here was the perfect chance to try it. He said if you don’t do chamber work the low lift numbers will be better. Hmmm perfect job to put that thinking to test. I removed some bad machine flashing left around one intake valve with a sanding roll. (Not the one I flow tested) I also relieved the spark plug holes (no affect on flow) and that was it, nothing more. I would have loved to added a 15 degree cut to the valve job but couldn’t because of the large 30 degree they cut. I added a 30 degree back cut to the speedmaster intake valves. I’m going to now retest the new speedmaster intake then port it but will start another port on that work. I have a few intakes I would like to test on this head. Ohhh I lapped in a couple of the valve jobs that came on the heads and if