Fuel Gauge

The general "flow."

1...Wiring. Wiring is always on your mind, how old are these girls. Bad connections at the cluster PC board for one

2...Bad instrument voltage limiter regulator

3...Bad sender or poorly calibrated aftermarket replacement sender.

4....Poor sender to tank ground

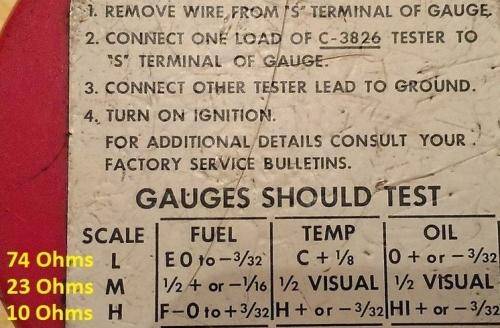

HOW TO START. One is to see if system OTHER than sender is OK. Two ways to do so. One way is to separate kick panel connector which goes to tail harness, ID the sender wire and use a decent digital meter to check resistance of sender. "Whatever that reads" interpolate that to what you think gauge should read. Here are the test resistances:

Second to this is get on egag or an electronics supplier and buy some test resistors, or obtain an old rheostat which will cover that range Both fuel and temp and oil if equipped gauges should read the same with same sender resistance.

This should give you an idea of "which half" of the system is bad--sender or gauge system

The general "flow."

1...Wiring. Wiring is always on your mind, how old are these girls. Bad connections at the cluster PC board for one

2...Bad instrument voltage limiter regulator

3...Bad sender or poorly calibrated aftermarket replacement sender.

4....Poor sender to tank ground

HOW TO START. One is to see if system OTHER than sender is OK. Two ways to do so. One way is to separate kick panel connector which goes to tail harness, ID the sender wire and use a decent digital meter to check resistance of sender. "Whatever that reads" interpolate that to what you think gauge should read. Here are the test resistances:

Second to this is get on egag or an electronics supplier and buy some test resistors, or obtain an old rheostat which will cover that range Both fuel and temp and oil if equipped gauges should read the same with same sender resistance.

This should give you an idea of "which half" of the system is bad--sender or gauge system