Sway Bars And Relocated Springs

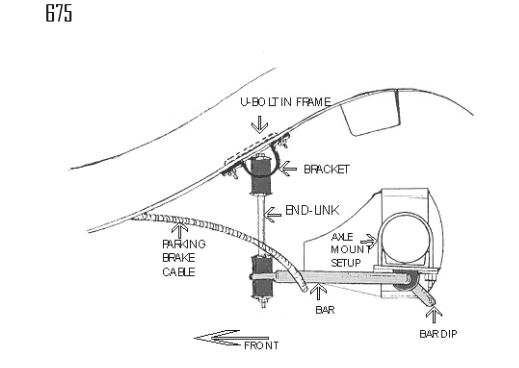

The Addco bars have the bracket that bolts through the frame rail vertically, and then has the single bolt end link style if I remember right. That would probably be the hardest version to adapt. There certainly are different end links you can buy that would be a horizontal bolt on one side and vertical on the other (you can also get the ball end type in this style, I think some modern Fords have this type).

Like 72bluNblu says, end links vertical and then the arms parallel to the ground is the best possible outcome. My only comment on the 72BBSwinger picture would be that I would highly recommend you hang the bar in double shear if it was this type with the bolts because I'm sure there's some bending going on there and it may eventually crack.

Now with that being said, some wacky ideas that may just work for you--- mounting the bar backwards so it hangs behind the axle and above which could be possible if you are not running exhaust through there. There are some factory ones like this (95-01 Ford Explorer comes to mind) These vehicles also have an s-curve in their horizontal bolt style end links. With the single bolt style you'd have to really improvise but not impossible.

And the last wacky idea - which is possible IF you have a solid sway bar is to literally just narrow it and weld it back together at the width you would like. My friend who's kind of a cowboy when it comes with just trying stuff - we once widened a Caprice 9C1 sway bar that was either 3/4" or 1" solid to fit his caprice wagon by about 2", just cut large bevels into the bar, added a chunk of solid steel bar in the middle, did some pre-heating, and then did a multi-pass mig weld with a regular 220V 190A mig on full power and then ground it smooth. That held up for 30k miles before he sold it. Do it at your own risk but it should work.

The Addco bars have the bracket that bolts through the frame rail vertically, and then has the single bolt end link style if I remember right. That would probably be the hardest version to adapt. There certainly are different end links you can buy that would be a horizontal bolt on one side and vertical on the other (you can also get the ball end type in this style, I think some modern Fords have this type).

Like 72bluNblu says, end links vertical and then the arms parallel to the ground is the best possible outcome. My only comment on the 72BBSwinger picture would be that I would highly recommend you hang the bar in double shear if it was this type with the bolts because I'm sure there's some bending going on there and it may eventually crack.

Now with that being said, some wacky ideas that may just work for you--- mounting the bar backwards so it hangs behind the axle and above which could be possible if you are not running exhaust through there. There are some factory ones like this (95-01 Ford Explorer comes to mind) These vehicles also have an s-curve in their horizontal bolt style end links. With the single bolt style you'd have to really improvise but not impossible.

And the last wacky idea - which is possible IF you have a solid sway bar is to literally just narrow it and weld it back together at the width you would like. My friend who's kind of a cowboy when it comes with just trying stuff - we once widened a Caprice 9C1 sway bar that was either 3/4" or 1" solid to fit his caprice wagon by about 2", just cut large bevels into the bar, added a chunk of solid steel bar in the middle, did some pre-heating, and then did a multi-pass mig weld with a regular 220V 190A mig on full power and then ground it smooth. That held up for 30k miles before he sold it. Do it at your own risk but it should work.