ply478

Well-Known Member

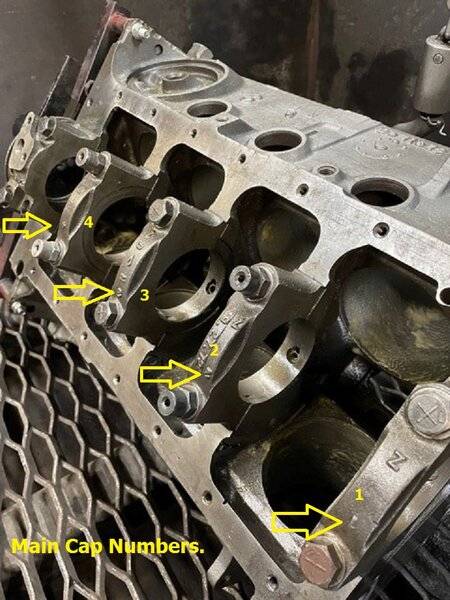

The main caps are in order front to back. 1-2-3-4

Numbers 2 & 4 Main Caps have the windage tray main stud bolts.

Look at the block main on #3 The groove for the thrust bearing machined into the block.

Then look at the #4 Main cap. There is the other groove for the other half of the main thrust bearing.

What the heck? Has anyone ever seen this before?

PLY478

Numbers 2 & 4 Main Caps have the windage tray main stud bolts.

Look at the block main on #3 The groove for the thrust bearing machined into the block.

Then look at the #4 Main cap. There is the other groove for the other half of the main thrust bearing.

What the heck? Has anyone ever seen this before?

PLY478