400/450 stroker....Cheap parts, lotta work.

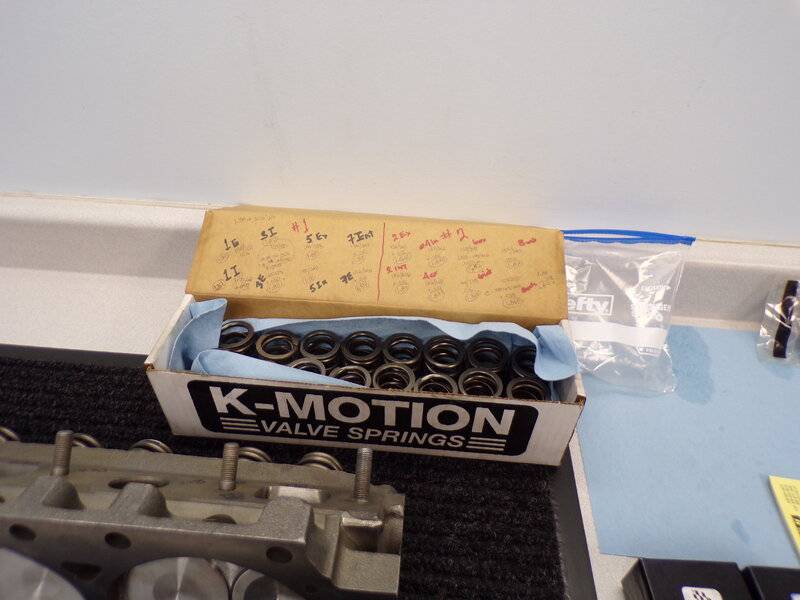

I'll probably hate myself for using these valve springs I took off of some OOTB Indy EZ heads. Spring pressures are all over the planet. I've had to use a lot of different spring shims to correct the pressures. Cheap parts, lotta work. I'm using some softer springs to break in the cam and lifters. Every final spring has been designated to a specific valve and is marked on the box so when we change over to them, after break in on the dyno, they'll be over the correct amount of shims. I just randomly placed the break in springs on the valves because that will be good enough for the no more than 3,000 rpm for break in.

I have to measure each valve, retainer, lock and spring locator combination and keep them together for that chamber.

Take the mic and retainer and set the spring tester to zero, then put a spring with the retainer on the tester and measure the height that gives me the correct seat pressure I want. Subtract the second measurement from the first and that gives me the amount of shims to put under the spring locator.

My old aluminum mic is a bit worn and checking the mic with the dial caliper says the mic reads .010" longer than what it actually is. I need to be smarter than the mic. God help me please.

I'll probably hate myself for using these valve springs I took off of some OOTB Indy EZ heads. Spring pressures are all over the planet. I've had to use a lot of different spring shims to correct the pressures. Cheap parts, lotta work. I'm using some softer springs to break in the cam and lifters. Every final spring has been designated to a specific valve and is marked on the box so when we change over to them, after break in on the dyno, they'll be over the correct amount of shims. I just randomly placed the break in springs on the valves because that will be good enough for the no more than 3,000 rpm for break in.

I have to measure each valve, retainer, lock and spring locator combination and keep them together for that chamber.

Take the mic and retainer and set the spring tester to zero, then put a spring with the retainer on the tester and measure the height that gives me the correct seat pressure I want. Subtract the second measurement from the first and that gives me the amount of shims to put under the spring locator.

My old aluminum mic is a bit worn and checking the mic with the dial caliper says the mic reads .010" longer than what it actually is. I need to be smarter than the mic. God help me please.