Another Boggie One

That all makes sense.

Keep at it and you'll keep improving it.

Sometimes there may be steps back as well as forward. It does take some time and fuel but its worth it.

That's a reasonable starting point.

Keep this in mind. They wrote that knowing the mechanical advance in the distributor would result in an initial timing around 10 to 14*.

End result was a good baseline for mid and top end performance and probably OK idle performance depending on the cam and engine.

Idle performance being the lower priority, and also the hardest to predict as there are so many different cams and compression ratios.

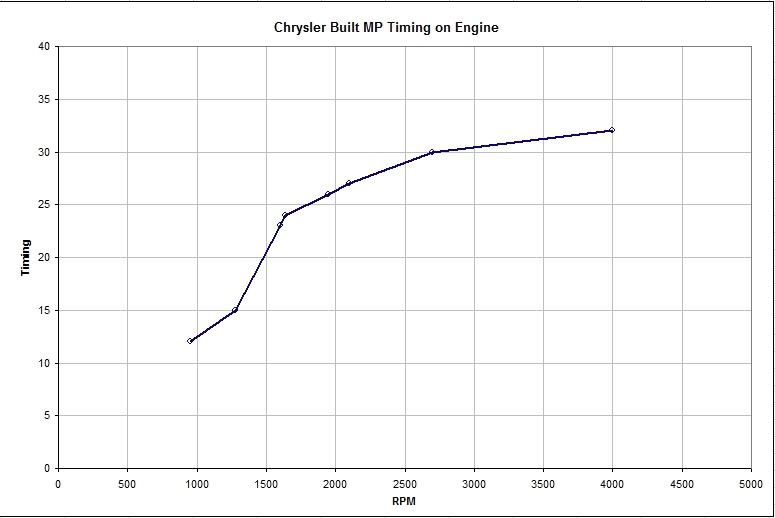

Here's a plot of the timing for the MP distributor when I set the timing to be 30* at 2700 rpm.

I didn't get the timing below 900 rpm that day, so I don't know the actual initial. (We sometimes learn from our mistakes! :) )

Anyway the point here is that your distributor probably has a different advance curve.

Perhaps the closest factory ones to the one above are in 273 4 bbl distributors (non-CAP).

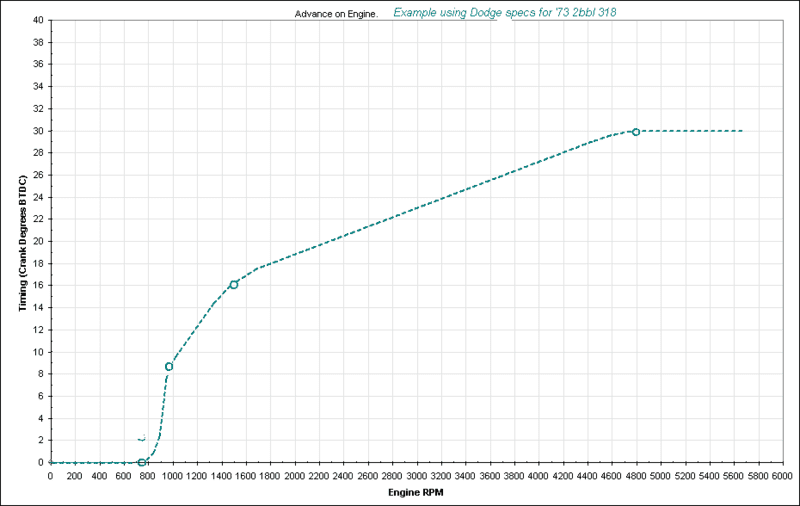

Any factory CAP/CAS distributors from the late 60s, early 70s will have a super quick and long initial advance.

Here's an example of that (from shop manual specs).

Notice how fast timing jumps up from 750 to 950 rpm. This was to make up for the fact it was purposely retarded at idle (compared with a non-CAP engine).

Using less initial timing made the cylinders hotter at idle so the combustion more completely consumed all of the hydrocarbons. The made less power, so higher idle speed was needed (750 rpm). The compromise here was entirely at idle. A little less efficiency in terms of power was traded for a lot less CO and HC out the exhaust. Above idle everything is pretty much back to normal.

That all makes sense.

Keep at it and you'll keep improving it.

Sometimes there may be steps back as well as forward. It does take some time and fuel but its worth it.

That's a reasonable starting point.

Keep this in mind. They wrote that knowing the mechanical advance in the distributor would result in an initial timing around 10 to 14*.

End result was a good baseline for mid and top end performance and probably OK idle performance depending on the cam and engine.

Idle performance being the lower priority, and also the hardest to predict as there are so many different cams and compression ratios.

Here's a plot of the timing for the MP distributor when I set the timing to be 30* at 2700 rpm.

I didn't get the timing below 900 rpm that day, so I don't know the actual initial. (We sometimes learn from our mistakes! :) )

Anyway the point here is that your distributor probably has a different advance curve.

Perhaps the closest factory ones to the one above are in 273 4 bbl distributors (non-CAP).

Any factory CAP/CAS distributors from the late 60s, early 70s will have a super quick and long initial advance.

Here's an example of that (from shop manual specs).

Notice how fast timing jumps up from 750 to 950 rpm. This was to make up for the fact it was purposely retarded at idle (compared with a non-CAP engine).

Using less initial timing made the cylinders hotter at idle so the combustion more completely consumed all of the hydrocarbons. The made less power, so higher idle speed was needed (750 rpm). The compromise here was entirely at idle. A little less efficiency in terms of power was traded for a lot less CO and HC out the exhaust. Above idle everything is pretty much back to normal.