400/450 stroker....Cheap parts, lotta work.

After installing the damper we needed to check the damper timing degree marks with the chain cover timing indicator. With the heads installed there would need to be a piston stop that was used in the #1 cylinder spark plug hole.

Enter a piston stop that Dad made for factory iron heads with an old spark plug, a piece of 3/8-16 all thread and a 3/8 jam nut. This same tool has been used by this family for at least 50 years.

With the crankshaft about 90 degrees before TDC on #1 cylinder, we install the piston stop in the #1 spark plug hole. Then slowly and GENTLY turn the crankshaft clockwise until it hits the pistons top. Mark a line on the damper corresponding to zero (0) on the cover timing tab.

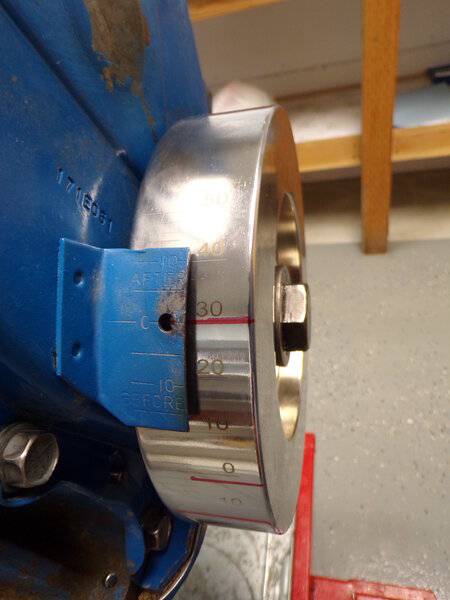

Then go counter-clockwise with crankshaft until the piston hits the stop in that direction and mark the damper again at where zero (0) is on the cover tab. This time it just happens to be at 30 degrees on the damper. Now turn the crankshaft a little clockwise and remove the piston stop. It is no longer needed and this will prevent you from smashing into the piston stop during the rest of the process.

Now we need to rotate the engine until we can measure and make a third mark in the center of the two marks we made. This will be TDC on #1 cylinder when the center red line on the damper is placed at zero on the timing cover. Let's do that....

Huh! The timing cover zero doesn't match the damper zero.

No Rob (RRR), after the aluminum intake manifold bolt down theory, we are not going to remark the entire damper to get the zeros to align.

I think we'll just put a line of paint on the timing cover tab corresponding to the damper zero. Because if we use the original timing cover zero and the damper zero, we're always going to be, what, in reality 2 degrees advanced from where we think we are? Sometimes I get really damned confused at this point.

After installing the damper we needed to check the damper timing degree marks with the chain cover timing indicator. With the heads installed there would need to be a piston stop that was used in the #1 cylinder spark plug hole.

Enter a piston stop that Dad made for factory iron heads with an old spark plug, a piece of 3/8-16 all thread and a 3/8 jam nut. This same tool has been used by this family for at least 50 years.

With the crankshaft about 90 degrees before TDC on #1 cylinder, we install the piston stop in the #1 spark plug hole. Then slowly and GENTLY turn the crankshaft clockwise until it hits the pistons top. Mark a line on the damper corresponding to zero (0) on the cover timing tab.

Then go counter-clockwise with crankshaft until the piston hits the stop in that direction and mark the damper again at where zero (0) is on the cover tab. This time it just happens to be at 30 degrees on the damper. Now turn the crankshaft a little clockwise and remove the piston stop. It is no longer needed and this will prevent you from smashing into the piston stop during the rest of the process.

Now we need to rotate the engine until we can measure and make a third mark in the center of the two marks we made. This will be TDC on #1 cylinder when the center red line on the damper is placed at zero on the timing cover. Let's do that....

Huh! The timing cover zero doesn't match the damper zero.

No Rob (RRR), after the aluminum intake manifold bolt down theory, we are not going to remark the entire damper to get the zeros to align.

I think we'll just put a line of paint on the timing cover tab corresponding to the damper zero. Because if we use the original timing cover zero and the damper zero, we're always going to be, what, in reality 2 degrees advanced from where we think we are? Sometimes I get really damned confused at this point.