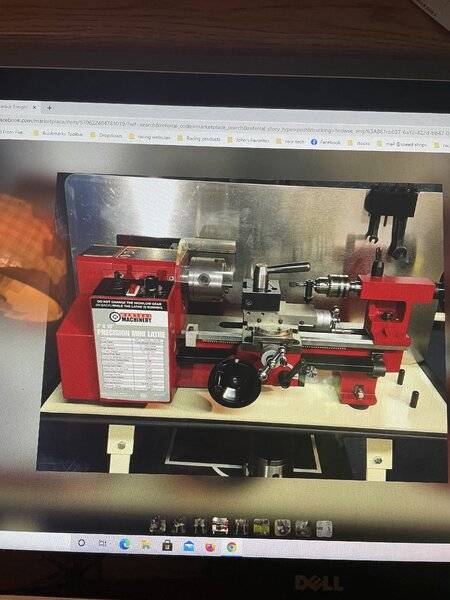

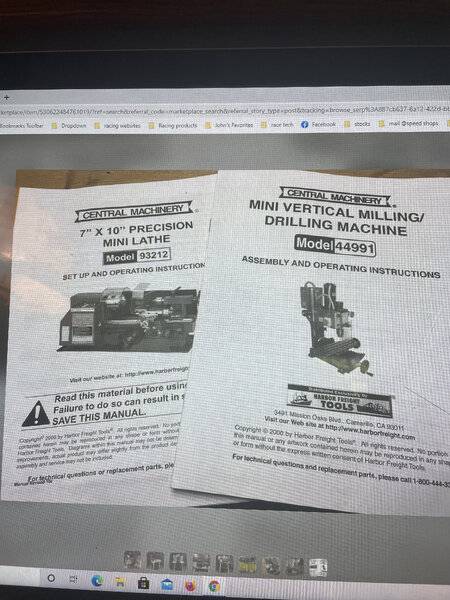

I found a Harbor freight mill and lathe for sale locally. Some updates were done and it looks like it’s been treated nicely. Have any of you guys owned or used either of these. What were your thoughts. He wants 1300.00 for everything.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harbor freight mill and lathe question

- Thread starter pittsburghracer

- Start date

-

Nope. It's a little dinky thing and Harbor Freight quality.

yellow rose

Overnight Sensation

The biggest issue is going to be the ability to take a decent cut. You can’t take big cuts and you really can’t crowd the tooling.

Back in late 2008 I bought a used Smithy lathe/mill combo for here at home. It paid for itself in the first 4 months. I never trust the dials on the machine and I use dial indicators on anything that has any tolerance.

Would I rather have a Bridgeport??? Absolutely. But those tools will do work if you understand their limitations and you don’t mind taking a little extra time.

Back in late 2008 I bought a used Smithy lathe/mill combo for here at home. It paid for itself in the first 4 months. I never trust the dials on the machine and I use dial indicators on anything that has any tolerance.

Would I rather have a Bridgeport??? Absolutely. But those tools will do work if you understand their limitations and you don’t mind taking a little extra time.

This would be the minumal you would need for work with soft metals, brass, copper, and aluminum. Really not suited for anything automotive...well maybe speedo repair?

I would suggest a "Smithy".

Smithy Machine Tools - Premium Machine Tools by Detroit Machine Tools

I would suggest a "Smithy".

Smithy Machine Tools - Premium Machine Tools by Detroit Machine Tools

My old boss used to have a mill very similar to that one.. I think it was set up for R8. He made a lot of ....stuff, with it but he wasn't much of a machinist.

The Lathe however, check out his YT video. (Tony) runs a mini lathe like that one through some tests.

Entertaining too.

The Lathe however, check out his YT video. (Tony) runs a mini lathe like that one through some tests.

Entertaining too.

gzig5

Well-Known Member

The lathe and mill must be considered a kit as they come from HF. They can be made into very usable machines. A lot of those little square column mills have been converted to CNC with good results. But, the work size envelope is extremely limited on both. You won't be doing any head work on that mill for instance. Not enough room under the spindle for tooling let alone fitting a head to the table. Finally, I think he is way too high on the price for used machines. If you could put them to use, I'd offer half his asking and walk away if he wouldn't accept it.

diymirage

HP@idle > hondaHP@redline

Maybe you oughta ask @Oldmanmopar where his boy shops?

Yard sales

SLOPAR72

Well-Known Member

You were a Millwright OP..... This is a Tinker toy for you. Unfortunately used mills have escalated in price however look in Auctions where a Manufacturing plant has closed. You can create a 3rd leg for 3 phase or go VFD.

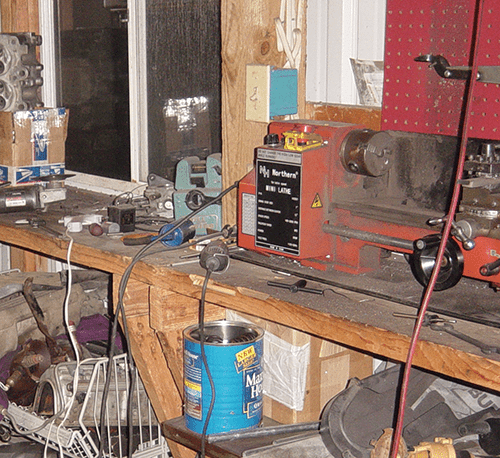

I only know one person who has spent the money on a small Lathe for doing work on very small projects and he didn't keep it long....

JW

I only know one person who has spent the money on a small Lathe for doing work on very small projects and he didn't keep it long....

JW

You were a Millwright OP..... This is a Tinker toy for you. Unfortunately used mills have escalated in price however look in Auctions where a Manufacturing plant has closed. You can create a 3rd leg for 3 phase or go VFD.

I only know one person who has spent the money on a small Lathe for doing work on very small projects and he didn't keep it long....

JW

I’m space limited till I get rid of some cars and if I get rid of some cars I wouldn’t need the tools. My buddy called the other day and I passed on his valve seat machine as I would easily have 2200.00 plus in it by time I upgraded it, maybe even more. Probably the only reason I paid attention to this is I have some plates to make up to use my W2 headers on my Edelbrock heads. I’ll probably end up doing them by hand like I’ve done everything else.

I have a big drill press here and I wonder if I could rough out these header adapter plates with a 1/4 inch end mill bit and finish them off by hand with a carbide burr. 3/8 inch thick aluminum

gzig5

Well-Known Member

If you are making new ones you can chain drill the profiles With a regular drill bit and then clean up with the file or grinder. If you’re modifying something you should be able to plunge an end mill without too much chatter in small increments. But drill press the bearings do not like sideloading

gzig5

Well-Known Member

On the other hand you can cut aluminum with woodworking tools so you could router it out if you needed to

On the other hand you can cut aluminum with woodworking tools so you could router it out if you needed to

No router either. I figured no matter what I was going to have to start by drilling a hole so I’ll go from there. The aluminum plate showed up today so I coated with blueing and will start laying it out tomorrow. I ordered a set of plates from Headman on Wednesday and he told me they were in stock but I had to order them from a vendor so I ordered them through summit.

It should work great, they use it for mass production in China.

A million workers and 3 million machines.

use your better judgement

A million workers and 3 million machines.

use your better judgement

I've owned the top-of-the-line HF mill, their high-end 3-n-1, and that very same table lathe. DON'T DO THE DEAL!! I had to replace every roll pin in the mac-daddy, the 3-in-1 still spins the lathe, but the mill quit shortly after I got it. Oh, and I bought 3 of those table lathes and all died.

famous bob

mopar misfit

This would be the minumal you would need for work with soft metals, brass, copper, and aluminum. Really not suited for anything automotive...well maybe speedo repair?

I would suggest a "Smithy".

Smithy Machine Tools - Premium Machine Tools by Detroit Machine Tools

i have a smithy , wish I`d got the biggest one they made. they have sold out to a place in new york i think, and down sized the inventory ------

dont know how i ever got along w/o one !

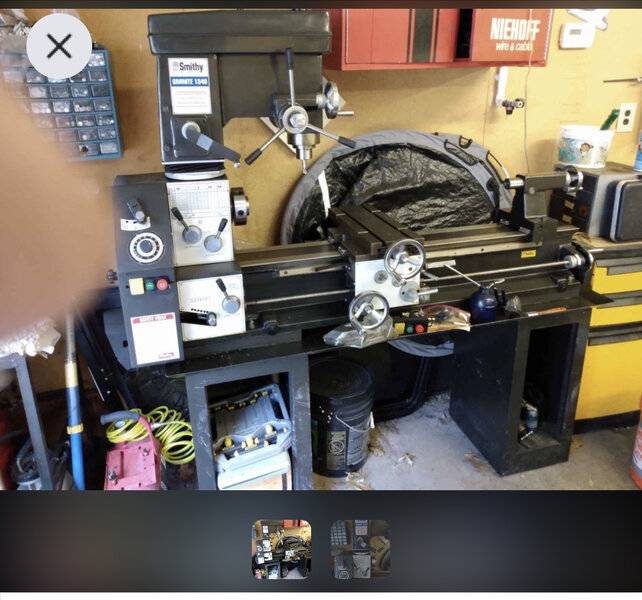

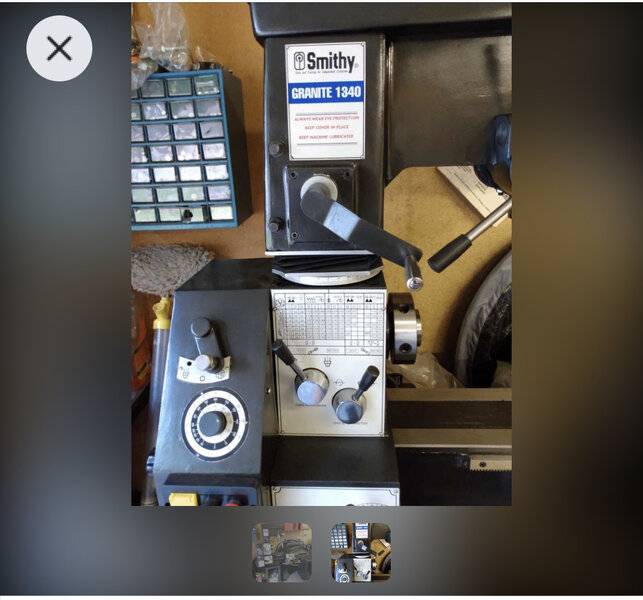

Well I found this one driving distance from home. Says 12 hours of use. 3500.00.

SLOPAR72

Well-Known Member

Well I found this one driving distance from home. Says 12 hours of use. 3500.00.

View attachment 1715756561

View attachment 1715756562

That's a step in the right direction. How much tooling?

JW

That's a step in the right direction. How much tooling?

JW

I’m working in the shop today so I didn’t call. The other one that I ask about above was marked sold and I’m glad you guys aimed me in another direction. I already have an idea LS craftsman lathe that I don’t use so I’m going to go slow and easy on this. I could have had a full size mill off a buddy for 2000.00 with tooling but like I said above I’m pretty stacked full here. If you say what I was doing by hand today you would be rolling on the floor laughing.

SLOPAR72

Well-Known Member

I’m working in the shop today so I didn’t call. The other one that I ask about above was marked sold and I’m glad you guys aimed me in another direction. I already have an idea LS craftsman lathe that I don’t use so I’m going to go slow and easy on this. I could have had a full size mill off a buddy for 2000.00 with tooling but like I said above I’m pretty stacked full here. If you say what I was doing by hand today you would be rolling on the floor laughing.

A Millwright can do things with basic tools that won't make sense to most people lol so what you are doing without a Mill wouldn't surprise me....

I ran across a sweet deal on a Knee Mill and Lathe a few years back with tooling and converted to VFD's and spent a day too many considering it. Those deals are few and far between today....

JW

mopar head

Well-Known Member

I hear ya, I`ts hard being a machinist with a drill press-die grinder-angel grinders and files, isn`t budI’m working in the shop today so I didn’t call. The other one that I ask about above was marked sold and I’m glad you guys aimed me in another direction. I already have an idea LS craftsman lathe that I don’t use so I’m going to go slow and easy on this. I could have had a full size mill off a buddy for 2000.00 with tooling but like I said above I’m pretty stacked full here. If you say what I was doing by hand today you would be rolling on the floor laughing.

-