67/68/69 cuda dilemma

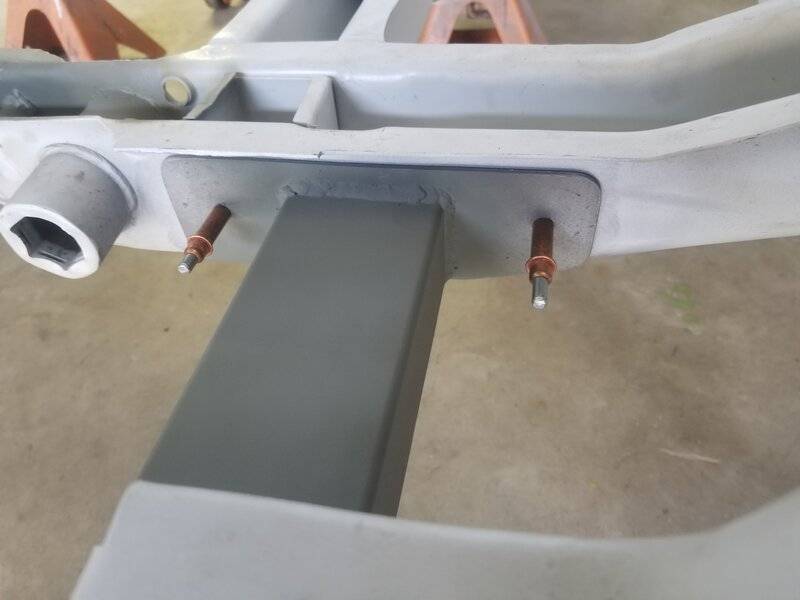

Tapered the subframe connector in since the framerail actually tapers a bit. The subframe connector fits so tight at the back now that currently the only things holding it pinned in place are the two 1/8" clecos in the front. The 5/16" holes at the back are for plug welds. It will also get lap welded at the framerail, and at the torsion bar crossmember. This car seems to be taking forever, but its hot out, and I am very picky at how stuff fits together. Must be the aviation sheetmetal mechanic in me, and once you weld it in, if it's wrong, it's a ***** to cut it back apart. After i weld this one in, the left side is next. Lots of pix, but I hope this thread helps others with some of this stuff.

Tapered the subframe connector in since the framerail actually tapers a bit. The subframe connector fits so tight at the back now that currently the only things holding it pinned in place are the two 1/8" clecos in the front. The 5/16" holes at the back are for plug welds. It will also get lap welded at the framerail, and at the torsion bar crossmember. This car seems to be taking forever, but its hot out, and I am very picky at how stuff fits together. Must be the aviation sheetmetal mechanic in me, and once you weld it in, if it's wrong, it's a ***** to cut it back apart. After i weld this one in, the left side is next. Lots of pix, but I hope this thread helps others with some of this stuff.