Distributor curve help needed

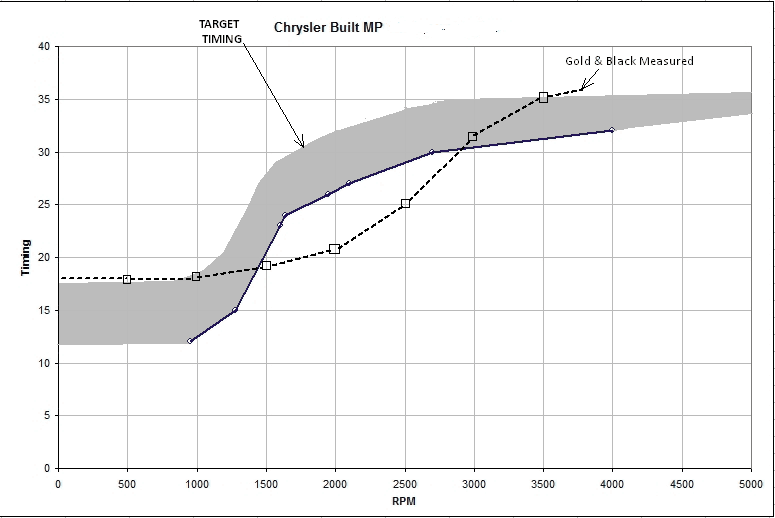

Made a goof in the graphs above (at 3500 rpm) when I plotted out the timing you measured.

Fortunately doesn't change the main point.

In gray is the range where I think the timing ought to be.

So the next question is how to get there.

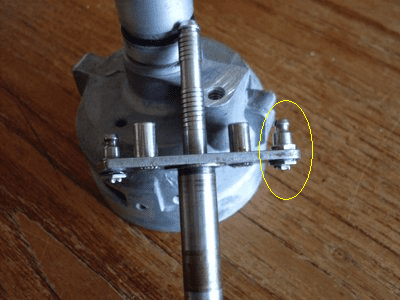

The first thing to do is reduce the tension of the primary spring. That's the spring with tension when the distributor isn't turning, or turning slow. On a Chrysler distributor you do that by turning the spring perch (circled).

You don't have to disassemble the distributor unless its really stubborn.

You can file a screwdriver into a tool to adjust from the top.

Or,

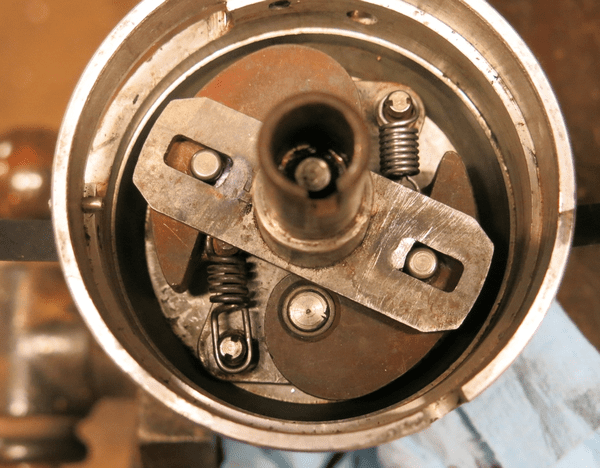

if both springs have tension on them, then turn both spring perches until they have the least amount of tension.

Or, better yet, if both springs have tension replace one spring with a long looped spring. In that case, don't reduce the tension on the primary spring. Not yet. Test first.

Example of a long looped spring.

The loop length and perch position determine how many degrees into the advance the second spring begines to assist.

But that's for later.

Made a goof in the graphs above (at 3500 rpm) when I plotted out the timing you measured.

Fortunately doesn't change the main point.

In gray is the range where I think the timing ought to be.

So the next question is how to get there.

The first thing to do is reduce the tension of the primary spring. That's the spring with tension when the distributor isn't turning, or turning slow. On a Chrysler distributor you do that by turning the spring perch (circled).

You don't have to disassemble the distributor unless its really stubborn.

You can file a screwdriver into a tool to adjust from the top.

Or,

if both springs have tension on them, then turn both spring perches until they have the least amount of tension.

Or, better yet, if both springs have tension replace one spring with a long looped spring. In that case, don't reduce the tension on the primary spring. Not yet. Test first.

Example of a long looped spring.

The loop length and perch position determine how many degrees into the advance the second spring begines to assist.

But that's for later.