Small block TrickFlow heads part 1

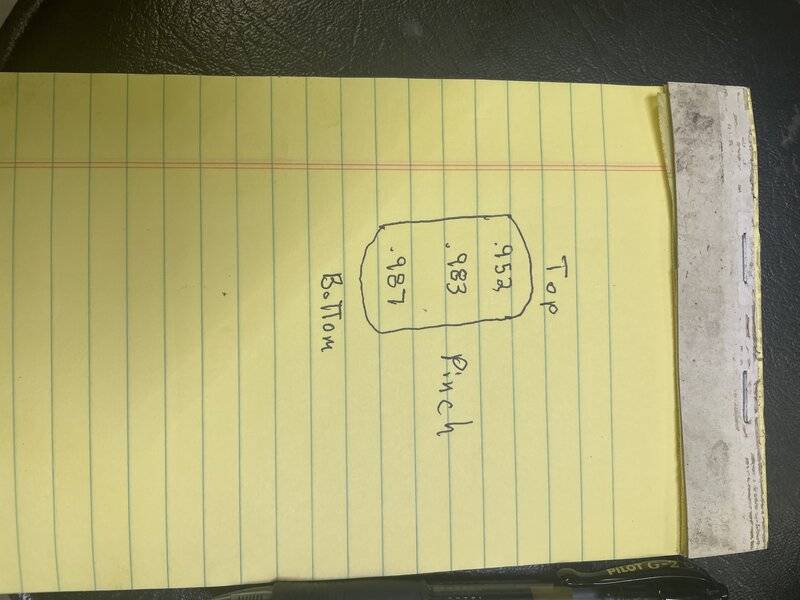

Ok here’s a little picture of the pinch measurements and as you can see it’s tapered. As I open it I’m technically moving the pinch towards the valve. Two things are going on. The common wall is tapered in as it goes towards the valve and the pinch wall tilts in. So as I open the pinch I’m also working it towards the valve. I’m going slow and easy because a fix would require me to break out the welder (I already fixed an intake today) I’ll remove.015-.020 and sonic check it. Even doing that it’s tricky. I’m not touching the common wall till after I flow it so I can give you guys an accurate figure. Snap gauges are your friend here and a cheap investment. Ohhh I’m up to 1.050 now and you should be able to see the difference. I’ll sonic check it after a small break and see if I can gain anymore. I would like to leave at least .050 of material.

Ok here’s a little picture of the pinch measurements and as you can see it’s tapered. As I open it I’m technically moving the pinch towards the valve. Two things are going on. The common wall is tapered in as it goes towards the valve and the pinch wall tilts in. So as I open the pinch I’m also working it towards the valve. I’m going slow and easy because a fix would require me to break out the welder (I already fixed an intake today) I’ll remove.015-.020 and sonic check it. Even doing that it’s tricky. I’m not touching the common wall till after I flow it so I can give you guys an accurate figure. Snap gauges are your friend here and a cheap investment. Ohhh I’m up to 1.050 now and you should be able to see the difference. I’ll sonic check it after a small break and see if I can gain anymore. I would like to leave at least .050 of material.