SM Head Install... forgetting anything?

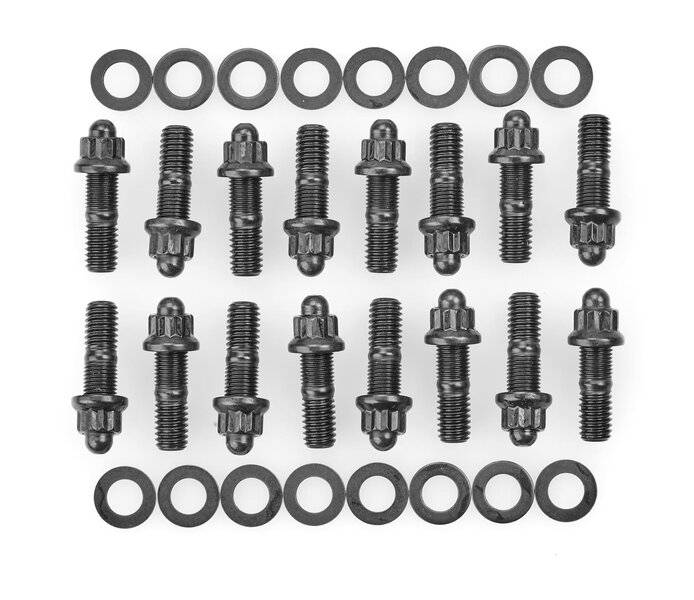

Use studs for the limited access locations, grind the stud to the exact length needed for the nuts thread engagement, round the end of the stud to aide slipping the nut on, but leave no excess threads exposed. Grind the nut thinner as needed but still be able to get a wrench “securely” in place to tighten. Grind the wrench as needed, thin it down. Radius the edges of the box end. Any one or combination of the above will work. Been there done that on many situations. 3/8”, 7/16” etc. Header bolts/ studs especially. You don’t need all that bolt head with washer length to fasten a couple header bolts.

Use studs for the limited access locations, grind the stud to the exact length needed for the nuts thread engagement, round the end of the stud to aide slipping the nut on, but leave no excess threads exposed. Grind the nut thinner as needed but still be able to get a wrench “securely” in place to tighten. Grind the wrench as needed, thin it down. Radius the edges of the box end. Any one or combination of the above will work. Been there done that on many situations. 3/8”, 7/16” etc. Header bolts/ studs especially. You don’t need all that bolt head with washer length to fasten a couple header bolts.