Squareback vs round back alternator?

The revised squarebacks are slightly larger than the regular ones.

Note the ballast resistor is meant to be a temperature sensitive device. The theory was that during highway speed driving it would be air cooled, and have less resistance so provide more current at these higher rpms. That would help compensate for the loss of time between sparks.

When the battery is turning the starter, the supply voltage is low. There also may be resistance in the circuit.

When the engine is running, the supply voltage at the alternator may be high. a little will be due to the regulator being temperature dependent. Cold engine compartment will result in slightly higher voltage. Often we find voltage of the alternator high due to resistance in the circuit. This is especially so immediately after starter because the high current supplied current for battery charging.

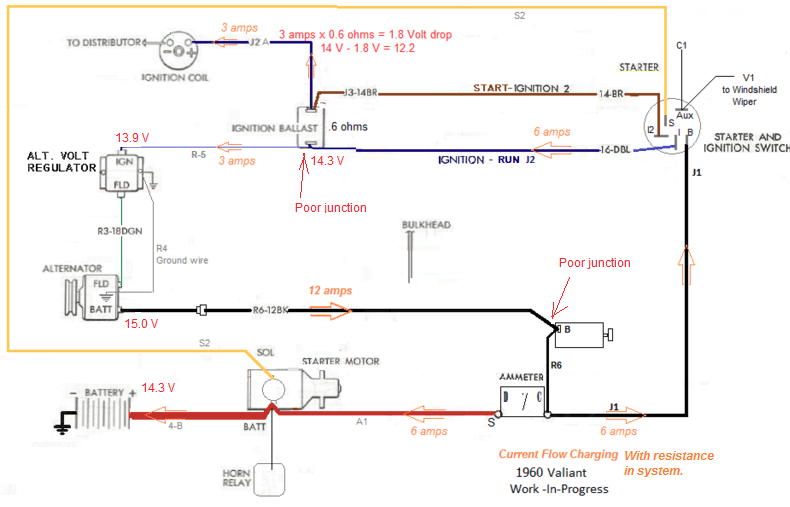

I don't know how you have rearranged the relays and extra fuses etc. So the following illustration is simply using the factory configuration. In this example there are two poor junctions and the rest of the wiring is perfect.

The alternator is producing power at 15.0 Volts.

WHY?

Because the regulator is sensing the system voltage is low. It brings the alternator voltage up enough so the regulator is at least seeing its minimum setpoint of 13.9 Volts.

The first voltage drop effects the entire system. All 12 amps flow through it. Voltage drops from 15 to 14.3 Volts.

change in V = I x R. 0.7 V = 12 amps x R

Therefore resistance is 0.06 Ohms.

It doesn't take much resistance to ruin our day.

As the battery charges, this voltage drop goes down.

The second voltage drop in this example is 0.4 Volts.

This will remain about the same since field and ignition requirements do not change significantly.

Troubleshoot by comparing voltages and/or directly measuring voltage drop between connections in the wiring.

The resistances are too small to read directly.

Also as Dana mentoned earlier, at idle speeds these alternators don't produce much power. With the engine around 700 to 800 rpm the power should be enough for most purposes. The shop manual load tests were at 1250 rpm.

The revised squarebacks are slightly larger than the regular ones.

Why?

Note the ballast resistor is meant to be a temperature sensitive device. The theory was that during highway speed driving it would be air cooled, and have less resistance so provide more current at these higher rpms. That would help compensate for the loss of time between sparks.

The measurements at the ballast connection need to be compared with the supply voltage.

When the battery is turning the starter, the supply voltage is low. There also may be resistance in the circuit.

When the engine is running, the supply voltage at the alternator may be high. a little will be due to the regulator being temperature dependent. Cold engine compartment will result in slightly higher voltage. Often we find voltage of the alternator high due to resistance in the circuit. This is especially so immediately after starter because the high current supplied current for battery charging.

I don't know how you have rearranged the relays and extra fuses etc. So the following illustration is simply using the factory configuration. In this example there are two poor junctions and the rest of the wiring is perfect.

The alternator is producing power at 15.0 Volts.

WHY?

Because the regulator is sensing the system voltage is low. It brings the alternator voltage up enough so the regulator is at least seeing its minimum setpoint of 13.9 Volts.

The first voltage drop effects the entire system. All 12 amps flow through it. Voltage drops from 15 to 14.3 Volts.

change in V = I x R. 0.7 V = 12 amps x R

Therefore resistance is 0.06 Ohms.

It doesn't take much resistance to ruin our day.

As the battery charges, this voltage drop goes down.

The second voltage drop in this example is 0.4 Volts.

This will remain about the same since field and ignition requirements do not change significantly.

Troubleshoot by comparing voltages and/or directly measuring voltage drop between connections in the wiring.

The resistances are too small to read directly.

Also as Dana mentoned earlier, at idle speeds these alternators don't produce much power. With the engine around 700 to 800 rpm the power should be enough for most purposes. The shop manual load tests were at 1250 rpm.