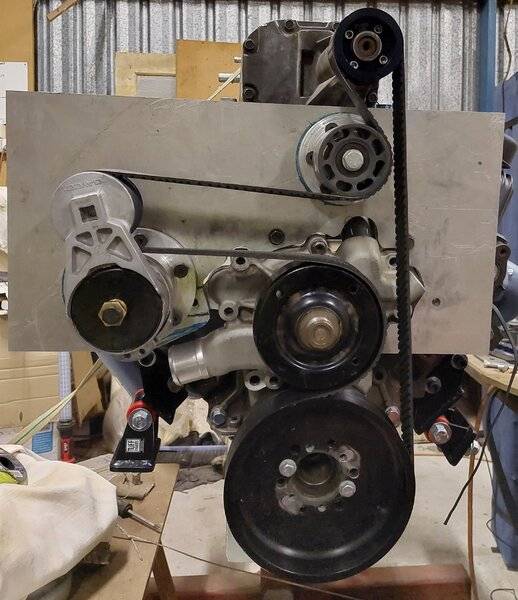

5.9 magnum with M122 blower/intercooler

Hey guys.

Been working on this for a while now, still a long way to go but it's starting to take shape.

Thought I'd share some pics I took recently.

(Edited for more info below)

The Blower and intercooler are both from an 07-12 Ford GT500 5.4L, these blowers are capable of supporting about 600hp on E85.

The intake manifold is a factory kegger which I modified myself to allow room for the intercooler. I cut the top off the manifold manually with a hand saw I made for performing a horizontal cut.

I will try to get pics of the inside of the manifold.. a LOT of material was gutted using air tools. The runners are almost non-existent now unfortunately.

The Crank pulley is a Vortech "universal" (does not fit mopar) 10-rib unit, it measures 7.8" diameter.

This is the largest possible pulley I could use while still clearing the magnum water pump pulley.

I had to fill the existing holes and redrill to suit the mopar dampener bolt pattern.

The supercharger snout is from a pontiac Grand prix GTP M90 as the GT500 snout was too short. It has 8 bolts instead of 7 and will need to be welded and redrilled.

The blower pulley is an Edelbrock piece that is made for their 10-rib E-force superchargers and measures 2.625" diameter. These are by far the most affordable 10-rib blower pulleys I could find. (I also have them in 2.75", 3.0" and 3.25" so I can turn the boost up/down)

The blower pulley is mounted on a 4-bolt hub that I made by machining down a factory steel press fit pulley in a lathe then drilled/tapped.

The spring loaded tensioner and idler are both from a Cummins ISX 12L diesel. Perhaps excessive. (you can't do too much to eliminate belt slip with a serpentine)

The tensioner is mounted on a 6 bolt bracket that can be rotated to adjust the position of the arm in small increments. (Just like adjusting a cam gear for more advance/retard)

This should be useful for adjusting preload, blower pulley diameter changes or to compensate for any belt stretch.

All the aluminium blower and accessory plates were machined using a makita wood router and single flute carbide bits, either freehand or using timber jigs.

I will be running a tank of water in the boot to feed the intercooler. to save on cost I will be using a mechanical belt-driven water pump from a jag AJ6 engine mounted as an accessory instead of an electric pump.

This should hopefully outperform most electric pumps at a fraction of the price anyway.

The engine itself is currently stock as a rock.

I'm tempted to gap the rings, upgrade the valve springs, install some MLS head gaskets and see how it responds.

Hey guys.

Been working on this for a while now, still a long way to go but it's starting to take shape.

Thought I'd share some pics I took recently.

(Edited for more info below)

The Blower and intercooler are both from an 07-12 Ford GT500 5.4L, these blowers are capable of supporting about 600hp on E85.

The intake manifold is a factory kegger which I modified myself to allow room for the intercooler. I cut the top off the manifold manually with a hand saw I made for performing a horizontal cut.

I will try to get pics of the inside of the manifold.. a LOT of material was gutted using air tools. The runners are almost non-existent now unfortunately.

The Crank pulley is a Vortech "universal" (does not fit mopar) 10-rib unit, it measures 7.8" diameter.

This is the largest possible pulley I could use while still clearing the magnum water pump pulley.

I had to fill the existing holes and redrill to suit the mopar dampener bolt pattern.

The supercharger snout is from a pontiac Grand prix GTP M90 as the GT500 snout was too short. It has 8 bolts instead of 7 and will need to be welded and redrilled.

The blower pulley is an Edelbrock piece that is made for their 10-rib E-force superchargers and measures 2.625" diameter. These are by far the most affordable 10-rib blower pulleys I could find. (I also have them in 2.75", 3.0" and 3.25" so I can turn the boost up/down)

The blower pulley is mounted on a 4-bolt hub that I made by machining down a factory steel press fit pulley in a lathe then drilled/tapped.

The spring loaded tensioner and idler are both from a Cummins ISX 12L diesel. Perhaps excessive. (you can't do too much to eliminate belt slip with a serpentine)

The tensioner is mounted on a 6 bolt bracket that can be rotated to adjust the position of the arm in small increments. (Just like adjusting a cam gear for more advance/retard)

This should be useful for adjusting preload, blower pulley diameter changes or to compensate for any belt stretch.

All the aluminium blower and accessory plates were machined using a makita wood router and single flute carbide bits, either freehand or using timber jigs.

I will be running a tank of water in the boot to feed the intercooler. to save on cost I will be using a mechanical belt-driven water pump from a jag AJ6 engine mounted as an accessory instead of an electric pump.

This should hopefully outperform most electric pumps at a fraction of the price anyway.

The engine itself is currently stock as a rock.

I'm tempted to gap the rings, upgrade the valve springs, install some MLS head gaskets and see how it responds.