K-Member / Rack & Pinion Steering Suggestions

this miight be ueful for anyone who doesn't want to spend a lot on aftermarket parts

the aussies went racing with their valiants in the 70s

they did the following to cater for uncapped roads harsh treatement of the cars, and racing... eventually all cars produced had similar mods on the production line

upper arm brackets had 1/4 circle gussets welded in one or two little 90* wedge gussets on the outide of the brackets.

all cars had torque boxes in the chassis regardless of model

all cars from 71 had a strengthening plate welded to the top off the inner wing on the plattue above the shock tower, it had a smooth stud pressed through a hole in it, that passed through the inner wing and through the top of the pressing that makes up the horn on the shock and upper arm support behind the wheel. this was threaded on the lower end and clamped the top of that section to the inner wing reducing flex

they ran v8 torsion bars in six cylinder cars

they had heavy duty spring hangers at the rear, some with 2 front mount positions to tweak under or over stear for different circuits

they used amtrong shocks that came with a range of different valving to cater for short tight and long sweeping curve tracks or street/police/towing

thay ran 16:1 ratio manual steering and manual brakes in both race cars and some police "chasers"

the cars were set up with 1/2 to 3/4 inch clerance between the chassis and the lower bump stop

most of their cars were lighter and the charger was 10 inches shorter and 60s b body width at the rear...

all race focused/ RT style cars ran single pot sliding calipers and anti sway bars.

i think if you get to this point you have a good baseline to work from and have a good basis for any future upgrade spend.... let the baseline dicate what you need.

the cars could corner in a manner that caused so much flex that the hood hit the edges of the fenders. obvioulsy this needs to be addressed.

if they had been allowed to by the race sanctioning bodies i'm sure a front lower radiator mounbt brace would have helped.

The following is an extract of a Chrysler Australia Service Bulletin dated June 1979.

SUBJECT: Loss of Wheel Alignment – Upper Control Arm Reinforcement

MODEL: All Valiant

To overcome problems of loss of wheel alignment mainly experienced with vehicles operated under severe conditions or unsealed roads a running change adding reinforcement plates to the upper control arm brackets was made in late 1978.

In the event that repeat loss of wheel alignment is experienced and fatigue cracking of the front attachment tab of the upper control arm bracket is noticed, on vehicle manufactured prior to the introduction of the reinforcement plate we recommend that the following corrective action is taken.

Dave

this miight be ueful for anyone who doesn't want to spend a lot on aftermarket parts

the aussies went racing with their valiants in the 70s

they did the following to cater for uncapped roads harsh treatement of the cars, and racing... eventually all cars produced had similar mods on the production line

upper arm brackets had 1/4 circle gussets welded in one or two little 90* wedge gussets on the outide of the brackets.

all cars had torque boxes in the chassis regardless of model

all cars from 71 had a strengthening plate welded to the top off the inner wing on the plattue above the shock tower, it had a smooth stud pressed through a hole in it, that passed through the inner wing and through the top of the pressing that makes up the horn on the shock and upper arm support behind the wheel. this was threaded on the lower end and clamped the top of that section to the inner wing reducing flex

they ran v8 torsion bars in six cylinder cars

they had heavy duty spring hangers at the rear, some with 2 front mount positions to tweak under or over stear for different circuits

they used amtrong shocks that came with a range of different valving to cater for short tight and long sweeping curve tracks or street/police/towing

thay ran 16:1 ratio manual steering and manual brakes in both race cars and some police "chasers"

the cars were set up with 1/2 to 3/4 inch clerance between the chassis and the lower bump stop

most of their cars were lighter and the charger was 10 inches shorter and 60s b body width at the rear...

all race focused/ RT style cars ran single pot sliding calipers and anti sway bars.

i think if you get to this point you have a good baseline to work from and have a good basis for any future upgrade spend.... let the baseline dicate what you need.

the cars could corner in a manner that caused so much flex that the hood hit the edges of the fenders. obvioulsy this needs to be addressed.

if they had been allowed to by the race sanctioning bodies i'm sure a front lower radiator mounbt brace would have helped.

The following is an extract of a Chrysler Australia Service Bulletin dated June 1979.

SUBJECT: Loss of Wheel Alignment – Upper Control Arm Reinforcement

MODEL: All Valiant

To overcome problems of loss of wheel alignment mainly experienced with vehicles operated under severe conditions or unsealed roads a running change adding reinforcement plates to the upper control arm brackets was made in late 1978.

In the event that repeat loss of wheel alignment is experienced and fatigue cracking of the front attachment tab of the upper control arm bracket is noticed, on vehicle manufactured prior to the introduction of the reinforcement plate we recommend that the following corrective action is taken.

- Remove the upper control arm from the upper control arm bracket (refer page 2-2-9 of the CL Service Manual).

- Weld all existing cracks or failed welds on the upper control arm bracket.

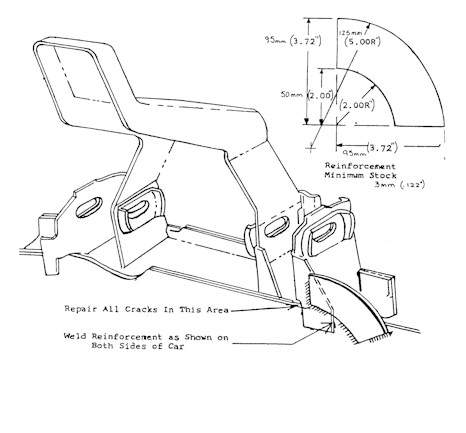

- Fabricate two reinforcements as shown in illustration below.

- Install reinforcement on both sides of the vehicle and weld as shown in illustration below. Clean up welded area and protect against corrosion using zinc rich primer and under body black.

- Reinstall upper control arm using new cam bolts and nuts.

- Measure and adjust vehicle height and wheel alignment. Note: Correct torque of the cam bolt nuts to 88 Nm (65 lbs./ft.) is important to prevent loss of wheel alignment as the result of movement of the cam bolts. It may be necessary to tighten the cam bolts using normal spanner then raise the wheels clear off the ground to provide clearance for the application of the torque wrench.

Dave