Carter Thermoquads ~ 'More General Information'

the early '69-'71 TQ's had downward angled nozzles.

the later '72-up TQ carbs, was add upward angled nozzles with air bleeds in the top nose, to allow air to pass through the top of the nozzle and mix with fuel. same as a Qjet.

but...the air metered and solid fuel metered both have air bleeds in the lid, in almsot the exact same place. that the solid fuel metered does, is merely move some bleeds close to/into the nozzle itself. for more fine control, for emissions. that's why Holleys 4bbl and the old CS carbs don't use solid fuel metering, they were not emission carbs, but strictly racing/performance carbs. that's also why Holleys get such lousy mileage, and were always pig rich (laughter...)but I still like my Holleys...they have their place.

the best illustrations for the difference, are the BBD 2-barrel on Mike's Carb Parts site. notice the "solid fuel metering" still has an air bleed facing forward in the nozzle cluster horizontally, in addition to an air bleed in the top nose of the upward facing nozzle, with a fuel discharge hole in the bottom of the nozzle.

basically solid fuel metering adds many more AIR BLEEDS, closer to the cluster/nozzle, which has the effect of leaning out the mixture, and adding emulsion to the mixture, and a finer control of the nozzle discharge.

Barry Grant was famous for doing the same thing with the Holley design, in his Demon carbs. instead of 2-3 emulsion air bleeds per barrel, there were 5-6 air bleeds per barrel. the idle/high speed air bleeds in the top were also larger than standard Holley bleeds for the same size carburetor. this can be a 2-edged sword in some applications. it delays primary activation, adds emulsions, and leans it, but then richens it at the top end. the air rushing into all those open air bleeds at WOT, has the effect of pushing the fuel out of the nozzles at WOT and high rpm. so it can create a top end rich condition.

BBD Identification

Air Bled & Solid Fuel

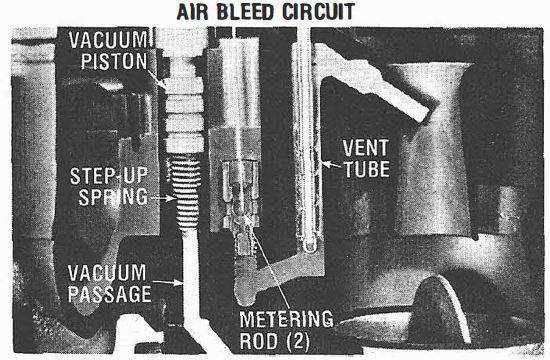

Air Bled

The air bled circuit used prior to 197 4 has an emulsion tube or vent tube that extends downward into the high speed well. This tube mixes air with the fuel before it leaves the high speed well. The air bled design always uses “down hill” nozzles. The air bleed in the high speed circuit also serve as-an anti-percolator passage.

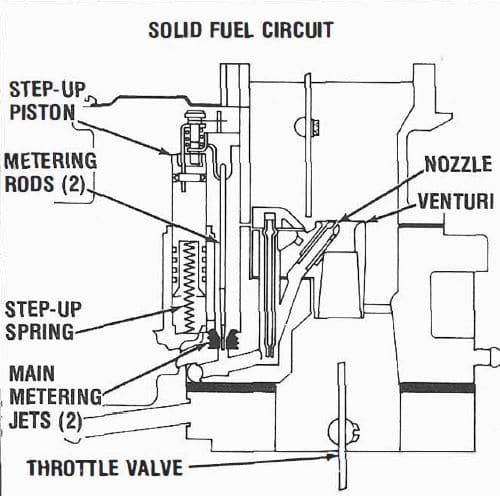

Solid Fuel

The solid fuel design, 1974 and ‘later, takes solid fuel from the high speed well and bleeds air into the circuit at the top through the extended vent tubes located in the cluster, closer to the tip of the nozzle. The solid fuel design always uses “uphill” nozzles and gives a closer calibration to meet the emission standards and also serves as an anti-percolator passage.

the early '69-'71 TQ's had downward angled nozzles.

the later '72-up TQ carbs, was add upward angled nozzles with air bleeds in the top nose, to allow air to pass through the top of the nozzle and mix with fuel. same as a Qjet.

but...the air metered and solid fuel metered both have air bleeds in the lid, in almsot the exact same place. that the solid fuel metered does, is merely move some bleeds close to/into the nozzle itself. for more fine control, for emissions. that's why Holleys 4bbl and the old CS carbs don't use solid fuel metering, they were not emission carbs, but strictly racing/performance carbs. that's also why Holleys get such lousy mileage, and were always pig rich (laughter...)but I still like my Holleys...they have their place.

the best illustrations for the difference, are the BBD 2-barrel on Mike's Carb Parts site. notice the "solid fuel metering" still has an air bleed facing forward in the nozzle cluster horizontally, in addition to an air bleed in the top nose of the upward facing nozzle, with a fuel discharge hole in the bottom of the nozzle.

basically solid fuel metering adds many more AIR BLEEDS, closer to the cluster/nozzle, which has the effect of leaning out the mixture, and adding emulsion to the mixture, and a finer control of the nozzle discharge.

Barry Grant was famous for doing the same thing with the Holley design, in his Demon carbs. instead of 2-3 emulsion air bleeds per barrel, there were 5-6 air bleeds per barrel. the idle/high speed air bleeds in the top were also larger than standard Holley bleeds for the same size carburetor. this can be a 2-edged sword in some applications. it delays primary activation, adds emulsions, and leans it, but then richens it at the top end. the air rushing into all those open air bleeds at WOT, has the effect of pushing the fuel out of the nozzles at WOT and high rpm. so it can create a top end rich condition.

BBD Identification

Air Bled & Solid Fuel

Air Bled

The air bled circuit used prior to 197 4 has an emulsion tube or vent tube that extends downward into the high speed well. This tube mixes air with the fuel before it leaves the high speed well. The air bled design always uses “down hill” nozzles. The air bleed in the high speed circuit also serve as-an anti-percolator passage.

Solid Fuel

The solid fuel design, 1974 and ‘later, takes solid fuel from the high speed well and bleeds air into the circuit at the top through the extended vent tubes located in the cluster, closer to the tip of the nozzle. The solid fuel design always uses “uphill” nozzles and gives a closer calibration to meet the emission standards and also serves as an anti-percolator passage.