A cautionary tale when working on push rods

I know this thread is a couple months old, but wanted to chime in with the experience I've had this week as well, in case others are wondering if this is common or experience something similar. Hopefully this will be useful. We have a fully rebuilt 318 LA engine with Edelbrock Performer RPM heads and Comp Cam cam, lifters and pushrods.

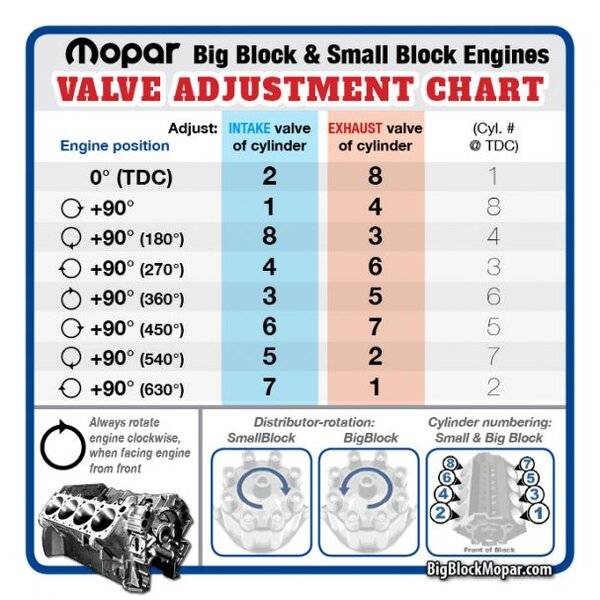

When we originally fired the engine up there was valve train noise and I couldn't ever get the timing to be stable at higher RPMs. We pulled the valve covers and re-set the pre-load/lash on all rocker arms using the Mopar 90 degree rotation method (see photo). We ran the engine and it seemed better. Within a few weeks the engine had developed a loud tick in the top end again. Pulled the VC and found a super loose rocker arm. So I tightened it up, put the VC back on. It sounded and ran better... for about 30 minutes... then the noises were back :).

So I pulled the intake and discovered the same exact issue that Charlie had with the lifter retainer clips failing. Turned out we had SEVEN clips that had popped out and 1 lifter that was essentially collapsed/stuck in the bore (see photos).

After breaking it in, we ran the engine up to 5K RPMs but I don't think that should be enough to hammer name brand components like this. It's quite possible that the initial pre-load wasn't enough (or too much?) and it caused the issue at start up. I just bought and installed Lunati lifters that have a different lifter clip (see photo) so I'm hoping it is more durable or forgiving. We should have it on the road again this weekend so I'll provide an update on what happens.

If anyone has some last minute advice on setting lash/pre-load with hydraulic flat tappet lifters, I'd love to hear it before I get this all buttoned back up.

I know this thread is a couple months old, but wanted to chime in with the experience I've had this week as well, in case others are wondering if this is common or experience something similar. Hopefully this will be useful. We have a fully rebuilt 318 LA engine with Edelbrock Performer RPM heads and Comp Cam cam, lifters and pushrods.

When we originally fired the engine up there was valve train noise and I couldn't ever get the timing to be stable at higher RPMs. We pulled the valve covers and re-set the pre-load/lash on all rocker arms using the Mopar 90 degree rotation method (see photo). We ran the engine and it seemed better. Within a few weeks the engine had developed a loud tick in the top end again. Pulled the VC and found a super loose rocker arm. So I tightened it up, put the VC back on. It sounded and ran better... for about 30 minutes... then the noises were back :).

So I pulled the intake and discovered the same exact issue that Charlie had with the lifter retainer clips failing. Turned out we had SEVEN clips that had popped out and 1 lifter that was essentially collapsed/stuck in the bore (see photos).

After breaking it in, we ran the engine up to 5K RPMs but I don't think that should be enough to hammer name brand components like this. It's quite possible that the initial pre-load wasn't enough (or too much?) and it caused the issue at start up. I just bought and installed Lunati lifters that have a different lifter clip (see photo) so I'm hoping it is more durable or forgiving. We should have it on the road again this weekend so I'll provide an update on what happens.

If anyone has some last minute advice on setting lash/pre-load with hydraulic flat tappet lifters, I'd love to hear it before I get this all buttoned back up.