Check out these nuts. (Problem solved)

Charrlie is correct. The reason why that nut is installed that way is because as the nut moves into the washer, it gets squozen which causes it to clamp onto the stud, making the 10 lb·ft torque come sooner than it otherwise would, in terms of the amount of clamping force on the manifold. This is necessary so the exhaust manifold can move as it heats and cools. Otherwise, with too much clamping force and restricted movement, -->crack.

Future readers of this thread, who aren't as fortunate as cruiser who had all his necessary hardware: read this (whole) thread for the dope on finding appropriate studs and nuts.

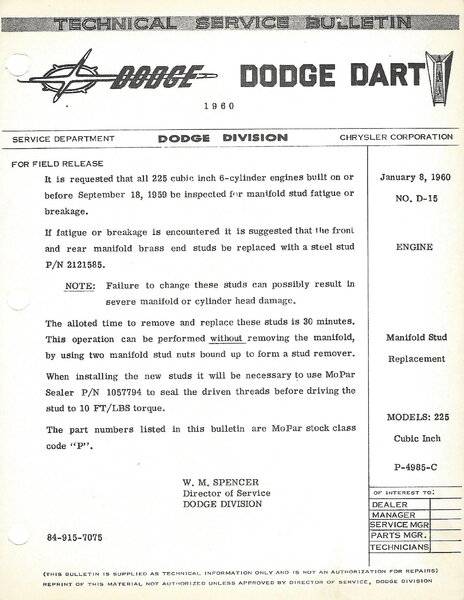

Oh, and the brass front and rear manifold-to-head studs were used on the very earliest Slant-6 engines made in 1959:

Charrlie is correct. The reason why that nut is installed that way is because as the nut moves into the washer, it gets squozen which causes it to clamp onto the stud, making the 10 lb·ft torque come sooner than it otherwise would, in terms of the amount of clamping force on the manifold. This is necessary so the exhaust manifold can move as it heats and cools. Otherwise, with too much clamping force and restricted movement, -->crack.

Future readers of this thread, who aren't as fortunate as cruiser who had all his necessary hardware: read this (whole) thread for the dope on finding appropriate studs and nuts.

Oh, and the brass front and rear manifold-to-head studs were used on the very earliest Slant-6 engines made in 1959: