The Great Pumpkin - '71 Duster

More progress to report on this car.

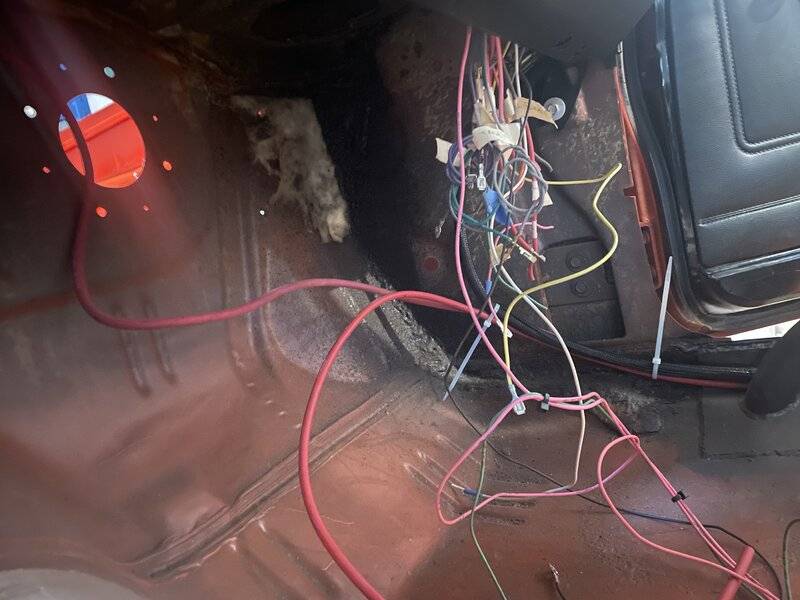

The re-wire job has finally commenced. The rear section of the main harness and the battery disconnect switch is mostly complete. Starting in the rear was the best way to attack this job since the longest runs of wire originate at this point. The disconnect switch is essentially where all the power comes from so it would not have made sense to start connecting things under the dash before seeing how the rearward wires would meet up with their termination points in front.

Initially, the plan was to use an aluminum battery box but due to having to more than one wire that needs to go directly to the battery itself, it would have made things more difficult since it required drilling several holes in the sides of the box to get the other wires to the terminals. Kind of defeats the purpose of having a closed battery box...

As you can see in the pic below, I dug out my old blue plastic Moroso battery box to help mock things up. Since I am installing a rear firewall to seal the passenger compartment from the trunk, it's no longer a requirement to have the battery in a sealed enclosure so I may just end up using a tray instead. I do prefer the idea of a box but the more stuff that has to connect to it the more of a P.I.T.A. it becomes. We'll see, maybe I can figure it out.

Whether it's visible or not, when finished, much of the wiring will be covered with expandable, nylon braided wire sheathing or split loom. I do like this stuff because it tidies things up nicely. It's not the "factory appearing" vinyl wrap but there's not much left on this car that is factory anything. The nylon braid stuff is easy to work with, lightweight, relatively inexpensive and does not involve adhesives of any kind.

The group of wires running up the passenger side in the next pic consists of the alternator charge wire, the Holley EFI main power and ground and the main feed to the fuse box from the disconnect switch. The rear lamp harness and main battery cable to the starter run up the driver's side. You can see the battery cable where it comes around the right rear down bar and routes across the front of the trunk under the package tray.

Even if you've only casually skimmed any Holley EFI literature in the last few years, you'll know that they relentlessly beat you over the head with the notion that the EFI main power and ground leads must go directly to the battery terminals. The idea is that the EFI needs "clean" power that isn't susceptible RFI and/or is not powering any other things with high current draw. Of course, having the battery in the trunk makes that 10x more difficult to execute, especially when you factor in a disconnect switch that has to shut the alterntor off as well.

I'm sure Holley repeats this phrase like a mantra because guys will inevitably find the easiest (stupidest) power supply they can tap into, like the coil + or a piggy back spade terminal tap to the radio power fuse. Everyone seems to know know better though because "that's how we did things back in the day." And besides, what does it matter, B+ is B+? But then wonder why they spent 2 grand on a fancy-new EFI system that won't work. They call the tech line and that's literally the first question they ask you. It's only a matter of time though before they throw in towel and yank the whole thing. Out comes the trusty old 4150 and then its time to come on the forums and bash EFI.

I've literally experienced this exact scenario with a neighbor who I helped install a Sniper system. His original, 55 year old wiring was trashed - the main battery cable was literally hanging on to the terminal by one strand of copper, no lie. I told him point blank he needed to rewire the car before even attempting to get the Sniper running or it would never work right. Even after offering to help, he was convincerd it was a weekend job and he'd be cruising in no time. He installed it himself and it wouldn't start. He didn't follow instructions and did a really poor job wiring the thing and changed none of the old woring out like I suggested. I couldn't even figure out what he did. He was ready to give up but I convinced him to fix the wiring and try again which he did. He eventualy got it running but if I wasn't pushing him to keep trying and making him focus on the correct wiring procedures, he'd be back to a carb. But I digress.

I'm sure you can run the main power to the B+ lug on the fuse box without any issue. But since I'm starting from scratch and have enough wire, I'm doing it the "right" way. :BangHead:

Here's the main dash harness mocked into place. I've removed all the unnecessary wires from it, saved a couple pounds and helps to keep clutter to a minimum. I'm a little stuck as to how I'm going to get the wires through the firewall though. The bulkhead connector that is supplied with the AAW harness kit is a GM part and it sucks. It basically does not fit the original opening. I mean why would it, it's from a completely different manufacturer. Their bulkhead also requires drilling two holes in your firewall to secure it, it does not utilie the factory clips. The two parts screw together to keep them tight which is not such a bad idea but since it does not fit, it inevitably cocks to one side when tightened in the slightest. Just garbage. I've already changed out their crazy fuse box so the bulkhead connector is just another step towards making it work in a Mopar application. Next time, I'll just buy a couple hundred bucks worth of wire and figure it out myself. I could probably make an entirely new harness with all the left over wire. Oh well.

As alluded to, I am working on a rear firewall. I'm not the type to just cut a piece of aluminum to fit, slap some rivets on it and call it done so of course this little project has become somewhat involved. A rear firewall must seal the passenger compartment from the trunk so that includes the package tray. It's not as easy as you'd think to fit stuff back here. There were cardboard templates involved and lots of trial and error.

Package tray templates. The carboard was from a food gift someone sent us. It was really nice cardboard!

Getting there. I will probably end up having to cut the bend at the front, at least on the far right piece. The package tray is sightly uneven where the sections meet and the panel sits a little crooked. I'm not sure how but the aluminum will eventualy get covered up.

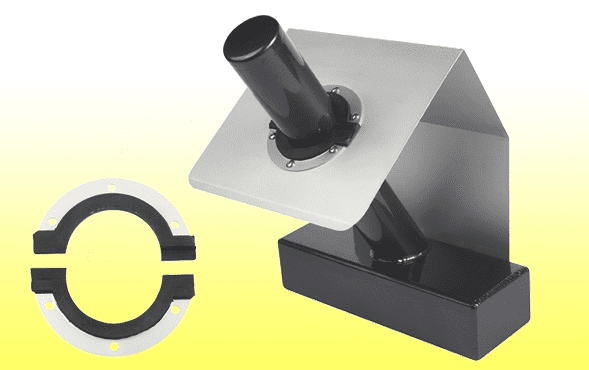

I need to figure out how to cover the gap around the rear bars. There are split grommets available for this exact purpose I'd love to be able to use but again, there's not enough room in front of the bar to secure it.

Like so;

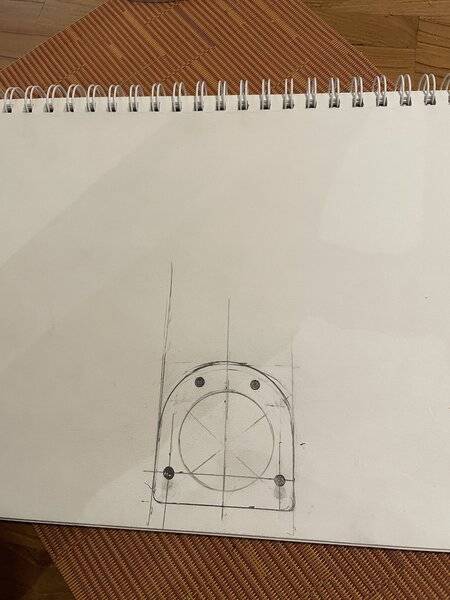

I have some scrap aluminum plate that I plan to use for a bezel. The thing will be visible so it has to look decent and fit fairly precisely. I gotta make two of these things so best to sketch it out first. It will be split horizontally so it will cover the seam. I'm gonna try real hard to cut straight lines and drill the holes equidistant. Neither of those skills are my strong suit.

Also kicking around the idea of a "rear seat delete." The approach will be slightly different from say the Super Stock Hemi Darts in that I'd like to cover the rear seat area with a raised platform of sorts. Figure I have to make some sort of basic frame and the aluminum sheet and fasten to that. I may or may not do this. I've already shown the rear firewall shape I cut out a few posts back. Thinking that will get covered in black vinyl if I can find a match for the door panel material.

This is a road sign which is around .080" thick and seems perfect for this. I only have the one right now, I might try to eh uh, find another one for the passenger side.

All for now. More to come.

More progress to report on this car.

The re-wire job has finally commenced. The rear section of the main harness and the battery disconnect switch is mostly complete. Starting in the rear was the best way to attack this job since the longest runs of wire originate at this point. The disconnect switch is essentially where all the power comes from so it would not have made sense to start connecting things under the dash before seeing how the rearward wires would meet up with their termination points in front.

Initially, the plan was to use an aluminum battery box but due to having to more than one wire that needs to go directly to the battery itself, it would have made things more difficult since it required drilling several holes in the sides of the box to get the other wires to the terminals. Kind of defeats the purpose of having a closed battery box...

As you can see in the pic below, I dug out my old blue plastic Moroso battery box to help mock things up. Since I am installing a rear firewall to seal the passenger compartment from the trunk, it's no longer a requirement to have the battery in a sealed enclosure so I may just end up using a tray instead. I do prefer the idea of a box but the more stuff that has to connect to it the more of a P.I.T.A. it becomes. We'll see, maybe I can figure it out.

Whether it's visible or not, when finished, much of the wiring will be covered with expandable, nylon braided wire sheathing or split loom. I do like this stuff because it tidies things up nicely. It's not the "factory appearing" vinyl wrap but there's not much left on this car that is factory anything. The nylon braid stuff is easy to work with, lightweight, relatively inexpensive and does not involve adhesives of any kind.

The group of wires running up the passenger side in the next pic consists of the alternator charge wire, the Holley EFI main power and ground and the main feed to the fuse box from the disconnect switch. The rear lamp harness and main battery cable to the starter run up the driver's side. You can see the battery cable where it comes around the right rear down bar and routes across the front of the trunk under the package tray.

Even if you've only casually skimmed any Holley EFI literature in the last few years, you'll know that they relentlessly beat you over the head with the notion that the EFI main power and ground leads must go directly to the battery terminals. The idea is that the EFI needs "clean" power that isn't susceptible RFI and/or is not powering any other things with high current draw. Of course, having the battery in the trunk makes that 10x more difficult to execute, especially when you factor in a disconnect switch that has to shut the alterntor off as well.

I'm sure Holley repeats this phrase like a mantra because guys will inevitably find the easiest (stupidest) power supply they can tap into, like the coil + or a piggy back spade terminal tap to the radio power fuse. Everyone seems to know know better though because "that's how we did things back in the day." And besides, what does it matter, B+ is B+? But then wonder why they spent 2 grand on a fancy-new EFI system that won't work. They call the tech line and that's literally the first question they ask you. It's only a matter of time though before they throw in towel and yank the whole thing. Out comes the trusty old 4150 and then its time to come on the forums and bash EFI.

I've literally experienced this exact scenario with a neighbor who I helped install a Sniper system. His original, 55 year old wiring was trashed - the main battery cable was literally hanging on to the terminal by one strand of copper, no lie. I told him point blank he needed to rewire the car before even attempting to get the Sniper running or it would never work right. Even after offering to help, he was convincerd it was a weekend job and he'd be cruising in no time. He installed it himself and it wouldn't start. He didn't follow instructions and did a really poor job wiring the thing and changed none of the old woring out like I suggested. I couldn't even figure out what he did. He was ready to give up but I convinced him to fix the wiring and try again which he did. He eventualy got it running but if I wasn't pushing him to keep trying and making him focus on the correct wiring procedures, he'd be back to a carb. But I digress.

I'm sure you can run the main power to the B+ lug on the fuse box without any issue. But since I'm starting from scratch and have enough wire, I'm doing it the "right" way. :BangHead:

Here's the main dash harness mocked into place. I've removed all the unnecessary wires from it, saved a couple pounds and helps to keep clutter to a minimum. I'm a little stuck as to how I'm going to get the wires through the firewall though. The bulkhead connector that is supplied with the AAW harness kit is a GM part and it sucks. It basically does not fit the original opening. I mean why would it, it's from a completely different manufacturer. Their bulkhead also requires drilling two holes in your firewall to secure it, it does not utilie the factory clips. The two parts screw together to keep them tight which is not such a bad idea but since it does not fit, it inevitably cocks to one side when tightened in the slightest. Just garbage. I've already changed out their crazy fuse box so the bulkhead connector is just another step towards making it work in a Mopar application. Next time, I'll just buy a couple hundred bucks worth of wire and figure it out myself. I could probably make an entirely new harness with all the left over wire. Oh well.

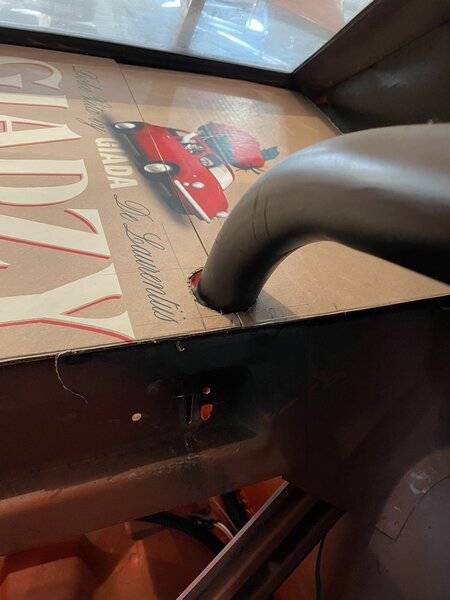

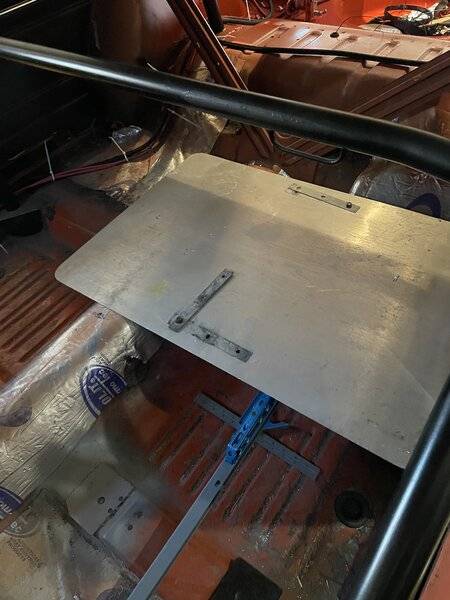

As alluded to, I am working on a rear firewall. I'm not the type to just cut a piece of aluminum to fit, slap some rivets on it and call it done so of course this little project has become somewhat involved. A rear firewall must seal the passenger compartment from the trunk so that includes the package tray. It's not as easy as you'd think to fit stuff back here. There were cardboard templates involved and lots of trial and error.

Package tray templates. The carboard was from a food gift someone sent us. It was really nice cardboard!

Getting there. I will probably end up having to cut the bend at the front, at least on the far right piece. The package tray is sightly uneven where the sections meet and the panel sits a little crooked. I'm not sure how but the aluminum will eventualy get covered up.

I need to figure out how to cover the gap around the rear bars. There are split grommets available for this exact purpose I'd love to be able to use but again, there's not enough room in front of the bar to secure it.

Like so;

I have some scrap aluminum plate that I plan to use for a bezel. The thing will be visible so it has to look decent and fit fairly precisely. I gotta make two of these things so best to sketch it out first. It will be split horizontally so it will cover the seam. I'm gonna try real hard to cut straight lines and drill the holes equidistant. Neither of those skills are my strong suit.

Also kicking around the idea of a "rear seat delete." The approach will be slightly different from say the Super Stock Hemi Darts in that I'd like to cover the rear seat area with a raised platform of sorts. Figure I have to make some sort of basic frame and the aluminum sheet and fasten to that. I may or may not do this. I've already shown the rear firewall shape I cut out a few posts back. Thinking that will get covered in black vinyl if I can find a match for the door panel material.

This is a road sign which is around .080" thick and seems perfect for this. I only have the one right now, I might try to eh uh, find another one for the passenger side.

All for now. More to come.