65amp wiring/trouble shooting

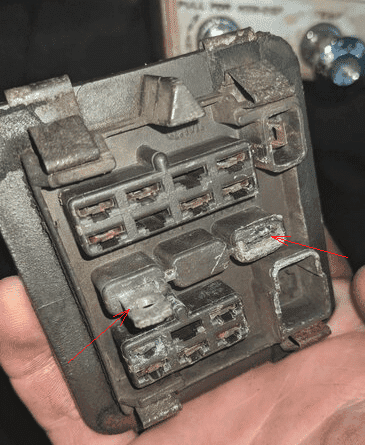

In most (all?) of the documented cases damage to the plastic is a consequence of high current going through resistance.

Paying attention to the meter will alert the driver that there is a problem developing or occuring.

The weakest point in the construction of the meter's themselves is the press fit of the studs to the plate. On some years and models these seem to have had an occassional tendency to get loose over time. Maybe not enough interference in the fit or the hardness of the metal on those particular models. Some people have reinforced the press fit by soldering. I don't normally suggest this option because its not a project to learn on.

When there is too much current for the meter, there is also too much current for the rest of the circuit.

The '63 and '65 main feed connections at the bulkhead are not dependent on press fit or spring action of the terminals.

But they still will get damaged by too much current. Each time a connection gets overheated, it speeds up oxidation, so resistance increases over time unless its cleaned up and fixed.

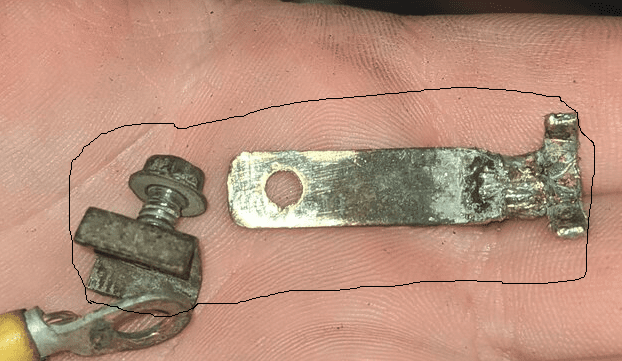

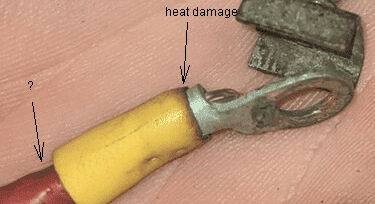

The engine bay wire itself also showed signs of overheating.

These are the wire terminals after the owner ran the engine for something like 20-30 minutes with ammeter pegged to charge.

That might help a little, but its not the cause. That piece is probably nylon or phenolic. You can look up the transistion temperature when those begine to flow (or if phenolic or bakelite) melt or burn.

In most (all?) of the documented cases damage to the plastic is a consequence of high current going through resistance.

Paying attention to the meter will alert the driver that there is a problem developing or occuring.

The weakest point in the construction of the meter's themselves is the press fit of the studs to the plate. On some years and models these seem to have had an occassional tendency to get loose over time. Maybe not enough interference in the fit or the hardness of the metal on those particular models. Some people have reinforced the press fit by soldering. I don't normally suggest this option because its not a project to learn on.

When there is too much current for the meter, there is also too much current for the rest of the circuit.

The '63 and '65 main feed connections at the bulkhead are not dependent on press fit or spring action of the terminals.

But they still will get damaged by too much current. Each time a connection gets overheated, it speeds up oxidation, so resistance increases over time unless its cleaned up and fixed.

The engine bay wire itself also showed signs of overheating.

These are the wire terminals after the owner ran the engine for something like 20-30 minutes with ammeter pegged to charge.