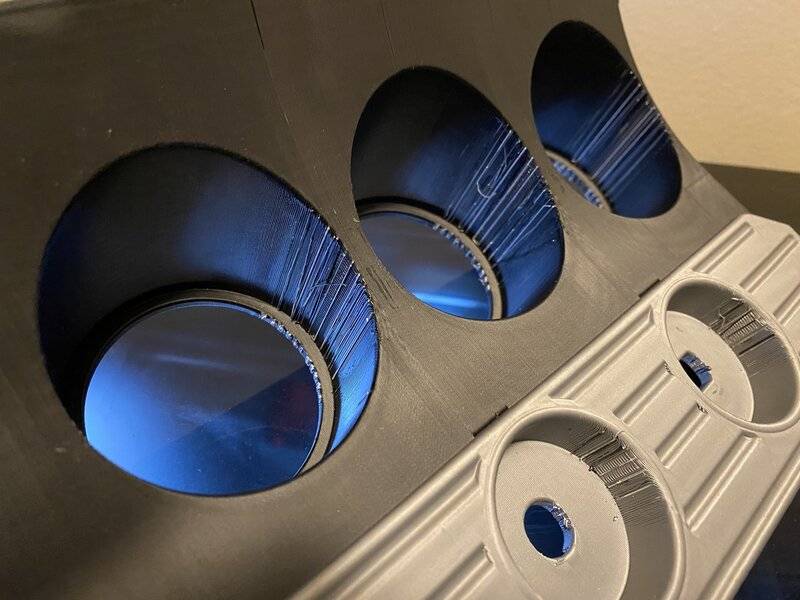

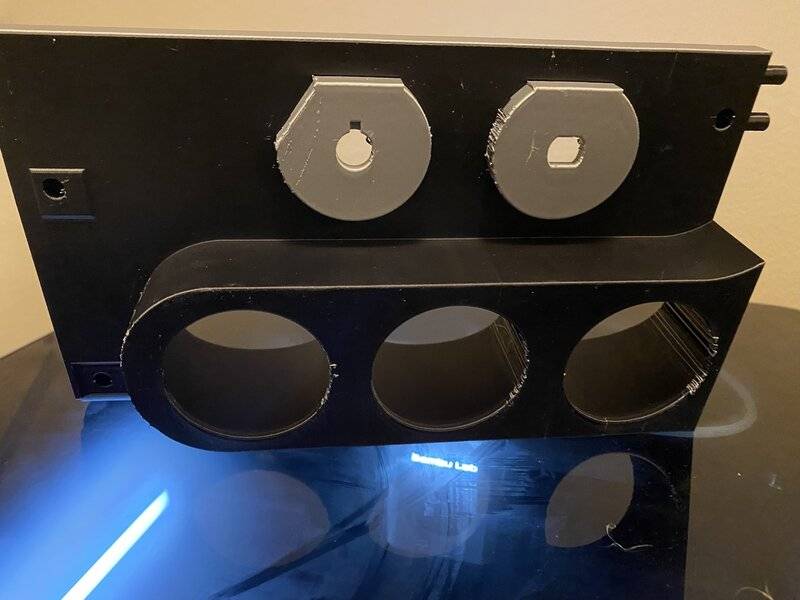

I'm 3D Printing a set of Dash Panels with Gauges

ok first full test print of piece #1 of the dashboard: mixed results. The issues that appeared are #1 warping again, and #2 the surface above the supports.

The warping I was hoping would be eliminated by printing it sideways, but it did still warp a little, not a lot...but enough to make a few cracks appear along layer lines. My options are: Try to install a mini heater in the enclosure to bring the temp up from 44c to around 60-65c, or chop the first piece into two separate pieces. The less you print, the less warp stress exists. This being the largest of the pieces may just be too much material at one time to not warp. If it was just one hairline crack I would be tempted to fill it with epoxy and call it done, as this is gonna have to get sanded and painted in the end.

The second issue is the rough surface where the top of the supports were. I can fix this if I do a bunch of testing and adjusting the support setting until it's dead on, or figuring out the issue with the support filament and how to better use it. If I can print it on its back instead of it's side, the issue moves to an area I don't care about, so in the end I may end up using all of these fixes...smaller part to print, more heat in the chamber, printing on it's back, and using the support filament.

Either way this print has also shown me I need to ventilate the space, so I've got to spend about $250 in supplies to vent the room with a fan going into the attic. Not a hard project, but it's going to cost me a few days. Anyway, in the end I will just keep trying different things until the print is right, so it's a matter of patience. By the way, the way this piece fits into the dashboard cutout is phenomenal...it practically holds itself in there with a bit of friction.

ok first full test print of piece #1 of the dashboard: mixed results. The issues that appeared are #1 warping again, and #2 the surface above the supports.

The warping I was hoping would be eliminated by printing it sideways, but it did still warp a little, not a lot...but enough to make a few cracks appear along layer lines. My options are: Try to install a mini heater in the enclosure to bring the temp up from 44c to around 60-65c, or chop the first piece into two separate pieces. The less you print, the less warp stress exists. This being the largest of the pieces may just be too much material at one time to not warp. If it was just one hairline crack I would be tempted to fill it with epoxy and call it done, as this is gonna have to get sanded and painted in the end.

The second issue is the rough surface where the top of the supports were. I can fix this if I do a bunch of testing and adjusting the support setting until it's dead on, or figuring out the issue with the support filament and how to better use it. If I can print it on its back instead of it's side, the issue moves to an area I don't care about, so in the end I may end up using all of these fixes...smaller part to print, more heat in the chamber, printing on it's back, and using the support filament.

Either way this print has also shown me I need to ventilate the space, so I've got to spend about $250 in supplies to vent the room with a fan going into the attic. Not a hard project, but it's going to cost me a few days. Anyway, in the end I will just keep trying different things until the print is right, so it's a matter of patience. By the way, the way this piece fits into the dashboard cutout is phenomenal...it practically holds itself in there with a bit of friction.