360 block limits

Hi, I run 400hp Nitrous (Doul Plate Edelbrock system on a Tunnel Ram) on a 1972 360 LA, and have for three years in my son 1977 2600lb F Body, and all I do is Magnaflux it every year. Here is how we do it, use it if you want, I will just put it out there for you to think about. The first thing I will tell you will cause all kinds of comments, it is always funny when I bring this part up. I am a Mechanical Engineer, my father was one as well, but he was also part of the design team members that designed the 360. When they started 360 the did not have a dedicated mold for the 360 so they used the 340 and stamped it 360 until mid 1973. This is getting sidetracked so I will, “in complete disclosure.” We have changed to the R Siamese Bore Blocks, with 4 bolt mains and girdle.

But back on topic, I will tell you what we do and you can decide if we are lucky or good.

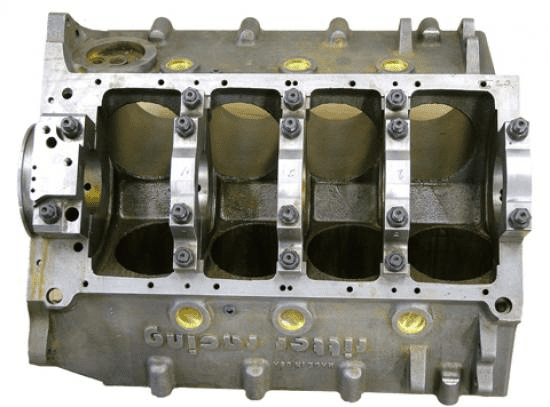

Block (2) 1971 blocks heat treated (Put in a kiln heated to 1500 degrees and cooled in 500 increments) and Magnaflux, Main studs and aligned honed, with girdle, the block was squared, with hard block. Heb McCandless oiling system (and yes it works great). 7qt oil pan

Now when it comes to the bottom end there are two thoughts “Strong or Soft” Aluminum Rod and caps or how we did it Strong Steel caps and H-Beam Rods, with free floating pistons, and a balanced rotating assembly.

Heads Edelbrock RPM with full Hughes Porting with needle bearing rockers with heavy walled cupped push rods and 1.6 rockers and 640 lift roller cam.

Gear drive cam gears

We like to use Ross piston at 0 deck, Flat Tops to allow for consist 360 pressure. 13.0 to 1 with Aluminum heads the engine thinks it is 1 CR less.

Modified or Nitrous Oxide - 0.005in x 4.00in bore = 0.020 inch ring gap. “we ran them at 0.024

Cams we run 112 to 114 center on the cams, 2 degrees of retard for every 100hp of NX, and a dedicated fuel pump and tank for the NX. 100 gph for every 100hp “so if you have a 400hp system you run 400 GPH fuel pump, with a 5 gal tank.

You can use Cometic TRI-Metal “0.040” gasket up to 250hp of NX after that its O-Ringing the Block and Copper Gaskets.

You can played with a time delay for activation, if you are running a 904 I would delay the activation until 0.002 after you shift to second gear. To comp for that you can run a 2.72 first gear and you will still have a good strong launch. The inherent weakness of the 904 is the 1 to 2 gear shift.

For 100 hp NX shot 2 degrees retard on timing, and run a bigger fuel pump, TM Head Gaskets and you will be fine. DO NOT RUN A DRY SYSTEM.

Hi, I run 400hp Nitrous (Doul Plate Edelbrock system on a Tunnel Ram) on a 1972 360 LA, and have for three years in my son 1977 2600lb F Body, and all I do is Magnaflux it every year. Here is how we do it, use it if you want, I will just put it out there for you to think about. The first thing I will tell you will cause all kinds of comments, it is always funny when I bring this part up. I am a Mechanical Engineer, my father was one as well, but he was also part of the design team members that designed the 360. When they started 360 the did not have a dedicated mold for the 360 so they used the 340 and stamped it 360 until mid 1973. This is getting sidetracked so I will, “in complete disclosure.” We have changed to the R Siamese Bore Blocks, with 4 bolt mains and girdle.

But back on topic, I will tell you what we do and you can decide if we are lucky or good.

Block (2) 1971 blocks heat treated (Put in a kiln heated to 1500 degrees and cooled in 500 increments) and Magnaflux, Main studs and aligned honed, with girdle, the block was squared, with hard block. Heb McCandless oiling system (and yes it works great). 7qt oil pan

Now when it comes to the bottom end there are two thoughts “Strong or Soft” Aluminum Rod and caps or how we did it Strong Steel caps and H-Beam Rods, with free floating pistons, and a balanced rotating assembly.

Heads Edelbrock RPM with full Hughes Porting with needle bearing rockers with heavy walled cupped push rods and 1.6 rockers and 640 lift roller cam.

Gear drive cam gears

We like to use Ross piston at 0 deck, Flat Tops to allow for consist 360 pressure. 13.0 to 1 with Aluminum heads the engine thinks it is 1 CR less.

Modified or Nitrous Oxide - 0.005in x 4.00in bore = 0.020 inch ring gap. “we ran them at 0.024

Cams we run 112 to 114 center on the cams, 2 degrees of retard for every 100hp of NX, and a dedicated fuel pump and tank for the NX. 100 gph for every 100hp “so if you have a 400hp system you run 400 GPH fuel pump, with a 5 gal tank.

You can use Cometic TRI-Metal “0.040” gasket up to 250hp of NX after that its O-Ringing the Block and Copper Gaskets.

You can played with a time delay for activation, if you are running a 904 I would delay the activation until 0.002 after you shift to second gear. To comp for that you can run a 2.72 first gear and you will still have a good strong launch. The inherent weakness of the 904 is the 1 to 2 gear shift.

For 100 hp NX shot 2 degrees retard on timing, and run a bigger fuel pump, TM Head Gaskets and you will be fine. DO NOT RUN A DRY SYSTEM.