66 Dart GT HT Whatsitgonnabe?

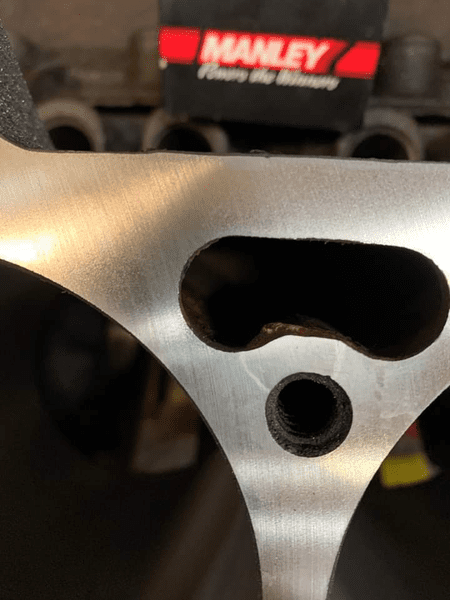

Today I welded what I thought were two cracks in a 440 block I sold a while back.

It turned out to be an old weld repair that had sort of come loose on one end. The other end was not really a crack, just a different material. There were some inclusions so I had to grind it down a bit.

I went and got some cast iron electrodes and practiced on a cracked head. Then I went to work. Built up patches and peened in between layers.

The top surface was tricky. It kept digging a crater so the weld crept closer and closer to the bore on one side. I finally managed to make it fuse with the top surface and after a rough grinding there is only a little porosity right next to the threads of the bolt hole.

I think that may disappear when the surface is decked once more. Whether the fix will hold remains to be seen. It’s my first time welding cast iron.

The reason I had to do this is that I sold the block and it was rough bored and decked before the machinist found the cracks. I ended up paying for the work so in order to salvage the block and still have a chance to make some money off it, I couldn’t have a professional do it.

If it holds, I’m good. If it cracks, I’m no worse off than I already was.

Anyway. We’ll see. I’m not sure if I should try drill and tap it standard size again or put in an insert.

Today I welded what I thought were two cracks in a 440 block I sold a while back.

It turned out to be an old weld repair that had sort of come loose on one end. The other end was not really a crack, just a different material. There were some inclusions so I had to grind it down a bit.

I went and got some cast iron electrodes and practiced on a cracked head. Then I went to work. Built up patches and peened in between layers.

The top surface was tricky. It kept digging a crater so the weld crept closer and closer to the bore on one side. I finally managed to make it fuse with the top surface and after a rough grinding there is only a little porosity right next to the threads of the bolt hole.

I think that may disappear when the surface is decked once more. Whether the fix will hold remains to be seen. It’s my first time welding cast iron.

The reason I had to do this is that I sold the block and it was rough bored and decked before the machinist found the cracks. I ended up paying for the work so in order to salvage the block and still have a chance to make some money off it, I couldn’t have a professional do it.

If it holds, I’m good. If it cracks, I’m no worse off than I already was.

Anyway. We’ll see. I’m not sure if I should try drill and tap it standard size again or put in an insert.