340 windage tray to oil pan edge fitment

Had the same issue but was more of a concern on my stroked 360. Edges were pushed in and the rods hit that rolled edge. Had to modify the tray to fit and clearance properly. On a 340 with shorter stroke that shouldn’t be a concern.

My original post about this:

Post on using the MP tray on a 360 with 4” stoke and oem rods:

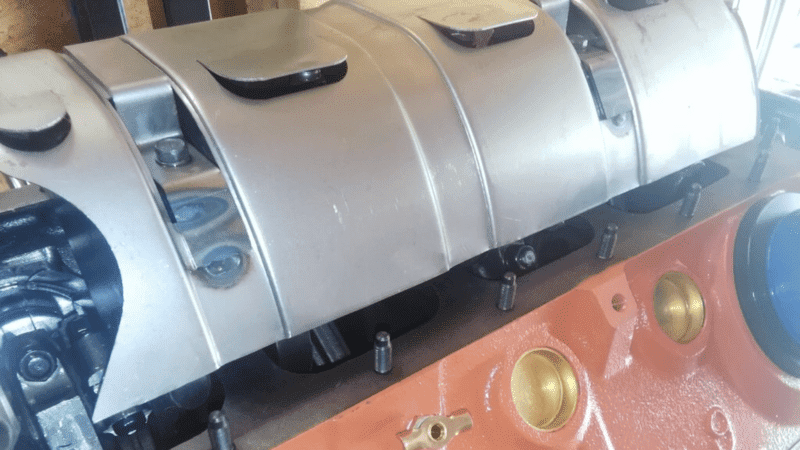

The picture above shows how the un-modified tray mounts, the curled ends extend outward onto the block oil pan rails. Note how close the rods are to the tray, and if the pan were installed with the tray “as is” the tray will compress inward and the rods will then contact it.

Had the same issue but was more of a concern on my stroked 360. Edges were pushed in and the rods hit that rolled edge. Had to modify the tray to fit and clearance properly. On a 340 with shorter stroke that shouldn’t be a concern.

My original post about this:

Post on using the MP tray on a 360 with 4” stoke and oem rods:

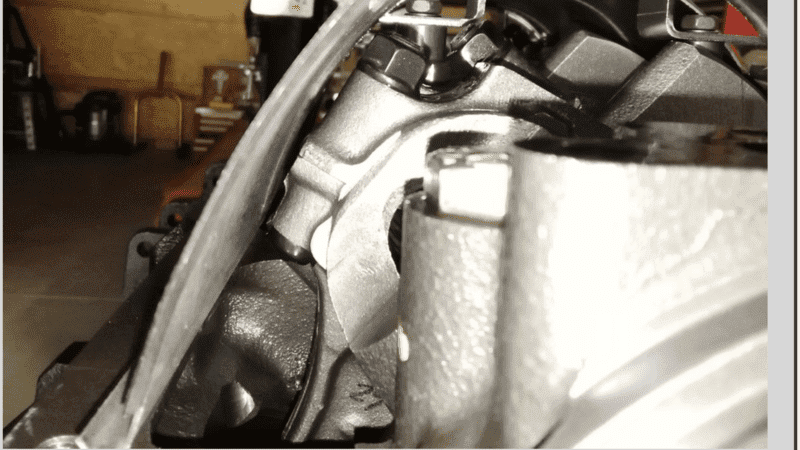

Note, when the pan is installed the edges of the windage tray (cut down, as shown in picture) fit close to the sides of the oil pan, so ignore the gap as shown between the tray edge and block.

The picture above shows how the un-modified tray mounts, the curled ends extend outward onto the block oil pan rails. Note how close the rods are to the tray, and if the pan were installed with the tray “as is” the tray will compress inward and the rods will then contact it.