The Great Pumpkin - '71 Duster

Been a rainy couple days here which helped facilitate some progress on the wiring front. I made a panel and set the EFI components in place. Little clunky but so far it seems like it should work. Did OK drilling the holes accurately, only muffed one or two this time.

The panel essentially occupies the same space as the heater box. At the front, it will screw into the the bottom of the dash under the glove box and will span the gap between the dash frame and firewall. It's supported at the firewall by the two lower blower motor delete plate bolts. It's solid.

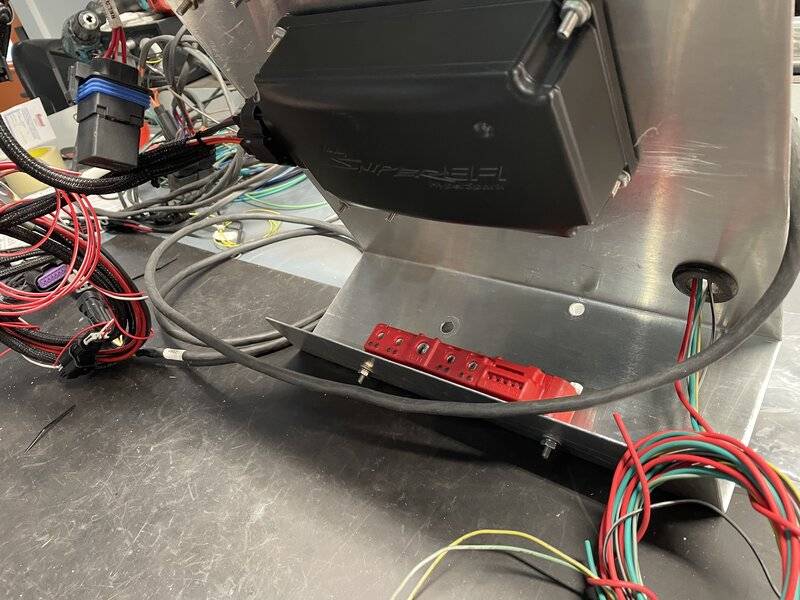

The initial plan was to make everything fit on the bottom side (see post #437) but there's no way that would have worked. Too cluttered, wires too short and strained, upside-down, etc. It's nice to have stuff in close proximity but it would have made the wiring a mess. Making the little shelf at the bottom of the panel for the relay module thing and putting the ignition box on the bottom were the right moves.

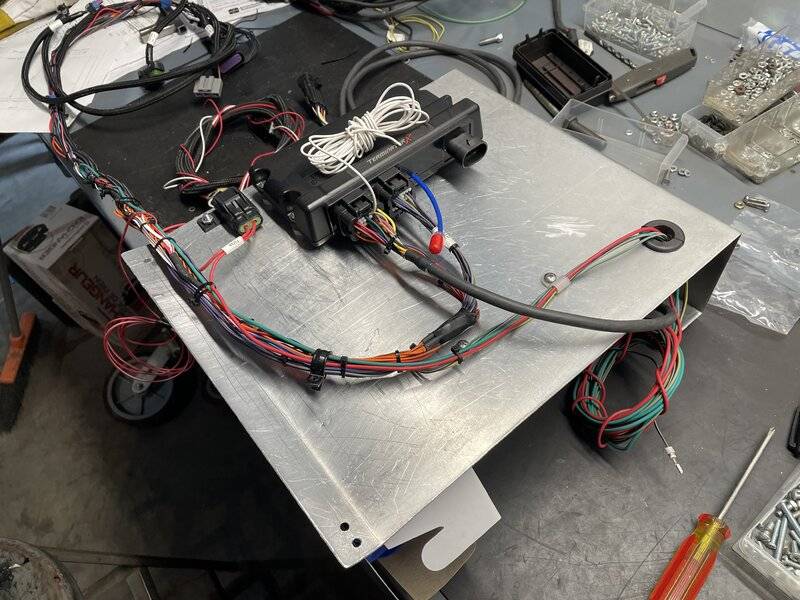

Once the components were in place I laid out the wiring in the car. The main focus was to make sure there was enough length to get the main harness across the dash and to the bulkhead connector. Essentially, I bundled everything up and routed it close to the way it will end up. That was a good thing to do because it confirmed that the panel was OK.

The blue tape markers on the left indicate where the harness turns towards the bulkhead and then terminates at the firewall. The wires going into the engine bay will get cut at the tape and terminated into a bulkhead connector. The wrapped up bundle in the middle there is the ignition box wiring. The only wires for the ignition that will go through the bulkhead are for the coil, evrything else goes to the ECU, fuse box or ground. The main power is supposed to go directly to the battery but I'm going to run it to the main B+ stud on the fuse box. Don't tell anyone.

Here's the other side. The empty connector on the ECU is for the main power and ground harness which is in the car. The wires that go through the grommet to the solid state relay are ECU 'output' wires that will control the electric water pump, cooling fan and fuel pump. The larger shrink tubed-bundle is the O2 sensor wiring. I broke it out of the main harness because it will route through the floor somewhere to get to the header collector. The blue tube with the red cap on it is for the internal MAP sensor. The signal comes from a vacuum port on the throttle body base plate and is connected directly to the ECU by a 3/16" vadcuum line. That's a nice feature since it eliminates the need to purchase and wire in another sensor.

Besides the FI wires, the forward light harness and whatever else that has to go through the firewall will be routed through this connector. This a Deutsch style bulkhead connector with solid contacts. The two sides twist together and lock tightly. I made a backing panel on the inside to keep the black bezel secured since it's just a hair larger than the OE bulkhead connector opening. This connector has it's limitations for sure but it's light years ahead of the old plastic part with the Packard 56 terminals.

Probably easy to see now why I was dreading this job so I'm glad to have made a dent in it. There is a ways to go but having the basic framework in place is helpful and encouraging.

More to come.

Been a rainy couple days here which helped facilitate some progress on the wiring front. I made a panel and set the EFI components in place. Little clunky but so far it seems like it should work. Did OK drilling the holes accurately, only muffed one or two this time.

The panel essentially occupies the same space as the heater box. At the front, it will screw into the the bottom of the dash under the glove box and will span the gap between the dash frame and firewall. It's supported at the firewall by the two lower blower motor delete plate bolts. It's solid.

The initial plan was to make everything fit on the bottom side (see post #437) but there's no way that would have worked. Too cluttered, wires too short and strained, upside-down, etc. It's nice to have stuff in close proximity but it would have made the wiring a mess. Making the little shelf at the bottom of the panel for the relay module thing and putting the ignition box on the bottom were the right moves.

Once the components were in place I laid out the wiring in the car. The main focus was to make sure there was enough length to get the main harness across the dash and to the bulkhead connector. Essentially, I bundled everything up and routed it close to the way it will end up. That was a good thing to do because it confirmed that the panel was OK.

The blue tape markers on the left indicate where the harness turns towards the bulkhead and then terminates at the firewall. The wires going into the engine bay will get cut at the tape and terminated into a bulkhead connector. The wrapped up bundle in the middle there is the ignition box wiring. The only wires for the ignition that will go through the bulkhead are for the coil, evrything else goes to the ECU, fuse box or ground. The main power is supposed to go directly to the battery but I'm going to run it to the main B+ stud on the fuse box. Don't tell anyone.

Here's the other side. The empty connector on the ECU is for the main power and ground harness which is in the car. The wires that go through the grommet to the solid state relay are ECU 'output' wires that will control the electric water pump, cooling fan and fuel pump. The larger shrink tubed-bundle is the O2 sensor wiring. I broke it out of the main harness because it will route through the floor somewhere to get to the header collector. The blue tube with the red cap on it is for the internal MAP sensor. The signal comes from a vacuum port on the throttle body base plate and is connected directly to the ECU by a 3/16" vadcuum line. That's a nice feature since it eliminates the need to purchase and wire in another sensor.

Besides the FI wires, the forward light harness and whatever else that has to go through the firewall will be routed through this connector. This a Deutsch style bulkhead connector with solid contacts. The two sides twist together and lock tightly. I made a backing panel on the inside to keep the black bezel secured since it's just a hair larger than the OE bulkhead connector opening. This connector has it's limitations for sure but it's light years ahead of the old plastic part with the Packard 56 terminals.

Probably easy to see now why I was dreading this job so I'm glad to have made a dent in it. There is a ways to go but having the basic framework in place is helpful and encouraging.

More to come.