Overhauling Heater/AC Box

Once I got the heater core installed (bent tube and all:BangHead:), I needed to test for leaks. I took a piece of 3/16 brake tubing and pushed it through a hole I drilled through a rubber stopper.

I used a second stopper to plug the other tube and immersed the whole thing in a container of water. I applied air to the open end of the tubing; no bubbles. I held the pressure for a little while till it finally popped the other stopper out of the tube, so I know it was pressurized.

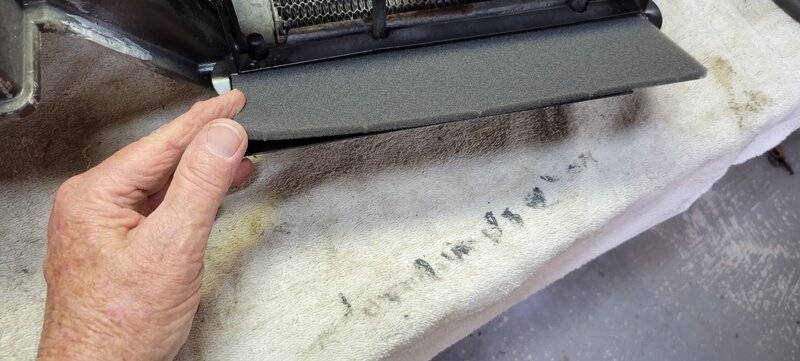

I used a foam and gasket kit from DMT to finish off the re-build.

I was careful to squeeze okum into the seams between box halves as well as into every little gap I could see.

I put all the retainer clips back in place to complete the re-assembly. It looks like my JB Weld sculpture work is holding just fine.

Once I got the heater core installed (bent tube and all:BangHead:), I needed to test for leaks. I took a piece of 3/16 brake tubing and pushed it through a hole I drilled through a rubber stopper.

I used a second stopper to plug the other tube and immersed the whole thing in a container of water. I applied air to the open end of the tubing; no bubbles. I held the pressure for a little while till it finally popped the other stopper out of the tube, so I know it was pressurized.

I used a foam and gasket kit from DMT to finish off the re-build.

I was careful to squeeze okum into the seams between box halves as well as into every little gap I could see.

I put all the retainer clips back in place to complete the re-assembly. It looks like my JB Weld sculpture work is holding just fine.