Stop in for a cup of coffee

Gale banks - an expert before there was youtube! :thumbsup:

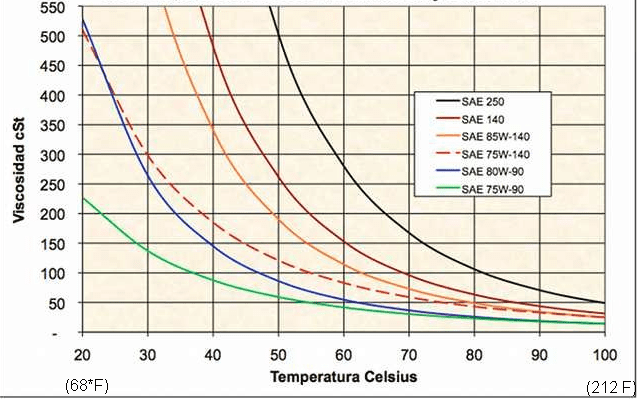

Here's a gear oil viscosity graph from Richard Widman.

Similar to motor oil, the non W grades are spec'd at 100 C (212*F).

So a 140 is about twice as viscous as a 90 at 212 F.

What is most interesting is the viscosity below 212 F, especially the multi-grades.

Keep in mind 90 is the thickest grade Chrysler spec'd before good multi-weights were on the market.

From here

https://www.widman.biz/English/Tables/gr-dif.html

He also has a white paper on the differences in GL4 vs GL5

https://www.widman.biz/English/Selection/oil.html

If you find it, that would be cool.

Gale banks - an expert before there was youtube! :thumbsup:

Here's a gear oil viscosity graph from Richard Widman.

Similar to motor oil, the non W grades are spec'd at 100 C (212*F).

So a 140 is about twice as viscous as a 90 at 212 F.

What is most interesting is the viscosity below 212 F, especially the multi-grades.

Keep in mind 90 is the thickest grade Chrysler spec'd before good multi-weights were on the market.

From here

https://www.widman.biz/English/Tables/gr-dif.html

He also has a white paper on the differences in GL4 vs GL5

https://www.widman.biz/English/Selection/oil.html