change in gas and temp gauges

You need to treat troubleshooting cluster/ gauges like an end to end system

That is: Proper 12.6--14.2 power to the cluster pin that supplies the gauge regulator/ IVR, and ground----and proper gauge readings with a given test resistor. THEN you can check the whole thing to the original senders.

Get some resistors so you can test the gauges. If you still have an OEM gauge voltage limiter, replace it with a solid state one like from RTE

Otherwise, generally problem areas in no particular order

1...the cluster connector pins are crimped and can corrode/ come loose. Clean them and solder to the board traces

2...Of course the gauges can become inaccurate

3...As mentioned, the IVR can become inaccurate

4...The "socket" where the IVR plugs in, those contacts can lose connection with the board traces. Clean and socler jumpers across from the contacts to the board traces

5....The studs on the gauges can lose contact with the board traces. Consider replacing the fake nuts with real ones. Loosen/ tighten the nuts several times to scrub the board copper clean

6....Cluster grounding is poor, and depended on mounting screws. Find a common ground point on the cluster, connect a grounding pigtail, and bolt that to the column support or the dash itself.

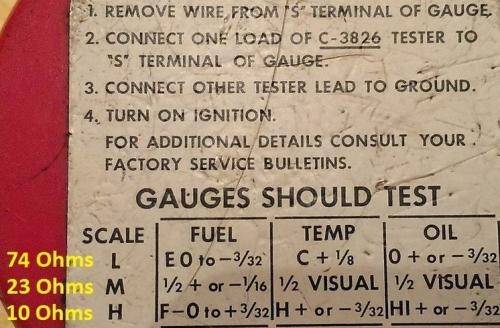

TEST the cluster/ gauges with test resistors. Here are the figures:

Once you KNOW the cluster works and have used resistors to verify that, THEN you can go after bad connections in the sender wires, or bad senders.

You need to treat troubleshooting cluster/ gauges like an end to end system

That is: Proper 12.6--14.2 power to the cluster pin that supplies the gauge regulator/ IVR, and ground----and proper gauge readings with a given test resistor. THEN you can check the whole thing to the original senders.

Get some resistors so you can test the gauges. If you still have an OEM gauge voltage limiter, replace it with a solid state one like from RTE

Otherwise, generally problem areas in no particular order

1...the cluster connector pins are crimped and can corrode/ come loose. Clean them and solder to the board traces

2...Of course the gauges can become inaccurate

3...As mentioned, the IVR can become inaccurate

4...The "socket" where the IVR plugs in, those contacts can lose connection with the board traces. Clean and socler jumpers across from the contacts to the board traces

5....The studs on the gauges can lose contact with the board traces. Consider replacing the fake nuts with real ones. Loosen/ tighten the nuts several times to scrub the board copper clean

6....Cluster grounding is poor, and depended on mounting screws. Find a common ground point on the cluster, connect a grounding pigtail, and bolt that to the column support or the dash itself.

TEST the cluster/ gauges with test resistors. Here are the figures:

Once you KNOW the cluster works and have used resistors to verify that, THEN you can go after bad connections in the sender wires, or bad senders.