Gasket matching vs. port matching.

"made as one" I get that's a good idea.

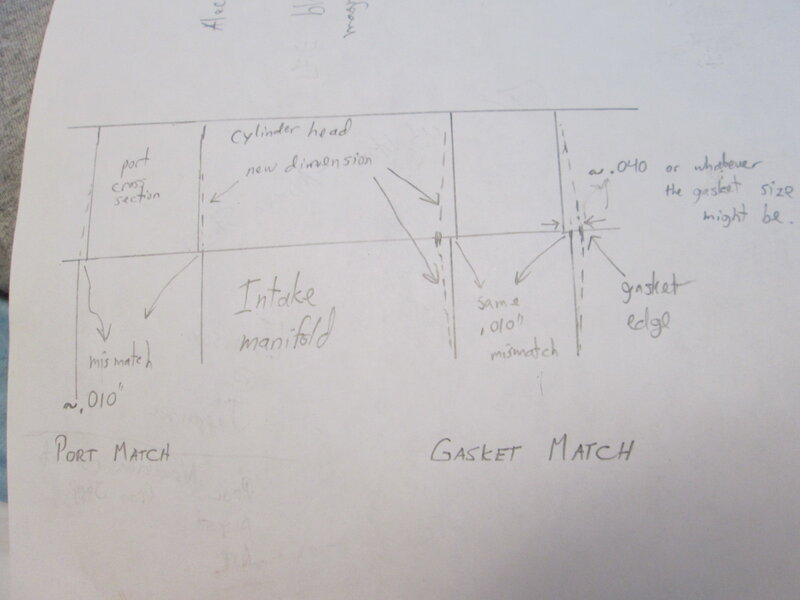

Yes, I'm saying port matching and gasket matching are two different things.

Port matching is correcting the head/intake mismatch just enough so the runners are aligned. Make a template method.

Gasket matching is grinding the head/intake runners to meet the edge of the gasket. This will increase port cross section area over a short distance. Removes a lot of metal beyond what is necessary to bring the port in alignment.

"Why gasket match" is the question. That takes time and effort to grind the additional metal away to the gasket edge. When removing a small amount would get the transition smooth.

Plus a large change in port cross section area for a short distance.

Why grind to the arbitrary size of the gasket opening?

"made as one" I get that's a good idea.

Yes, I'm saying port matching and gasket matching are two different things.

Port matching is correcting the head/intake mismatch just enough so the runners are aligned. Make a template method.

Gasket matching is grinding the head/intake runners to meet the edge of the gasket. This will increase port cross section area over a short distance. Removes a lot of metal beyond what is necessary to bring the port in alignment.

"Why gasket match" is the question. That takes time and effort to grind the additional metal away to the gasket edge. When removing a small amount would get the transition smooth.

Plus a large change in port cross section area for a short distance.

Why grind to the arbitrary size of the gasket opening?